https://www.youtube.com/watch?v=94v53KGuyLA

How Engines Are Made

Engines are made up of over 300 bolts and dozens of moving parts like pistons and valve springs that all work together to turn combustion into motion .

One part can be the difference between a powerful engine and catastrophic failure .

Here .

Blueprint manufactures 12,000 Chevy Ford and Chrysler compatible engines .

This is how it's done .

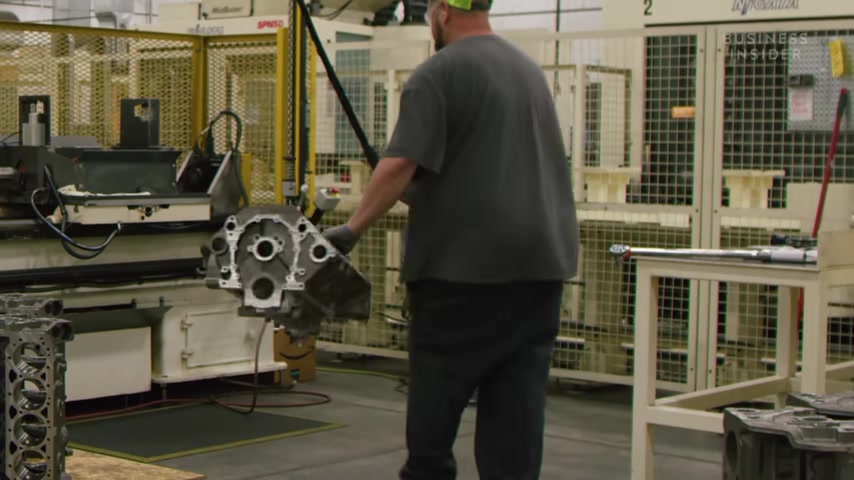

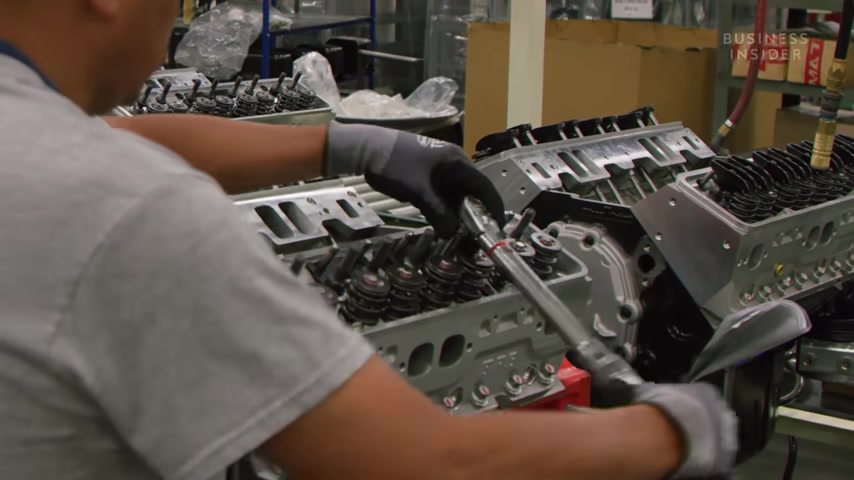

It all starts with the engine block which is the base that all the components will eventually connect to the blocks come pre forged and are built to blueprint specifications .

The cavities you see here are designed to fit the pistons and connecting rods .

Here , the gas ignites and pushes the two components up and down .

This causes the connecting rods to spin the crankshaft , turning the linear motion into a rotational motion that will ultimately drive the wheels .

But to get here , the cavities are resized to fit the components .

That's where the aligned hone machine comes in here .

The center of the block is cut to size to fit the crankshaft which will be installed later in the process , the metal shavings are cleaned off and the block is sent to the cylinder home here .

AC N C machine cuts the cylinders to fit the pistons .

After a worker inspects each cylinder for cross hatches .

These are tiny xli scratches that hold oil and allow the piston to glide smoothly inside the cavity .

Then it's sent for a wash .

Mhm .

This removes any metal shaving stuck to the block which can cause catastrophic damage if they cycle through the running engine on the other side of the warehouse , the rest of the components are assembled , tested and prepped for their marriage to the block .

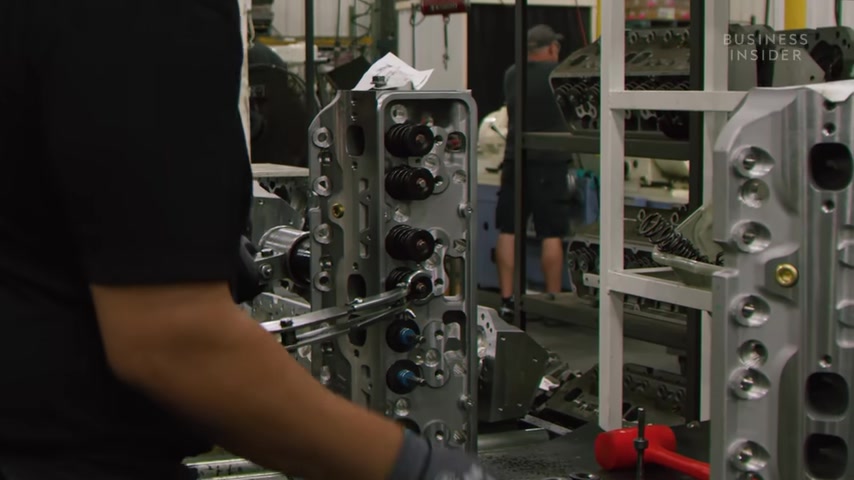

The cylinder head helps to form the combustion chamber where the gas is ignited like the block , the cylinder head is pre forged and delivered to blueprints factory .

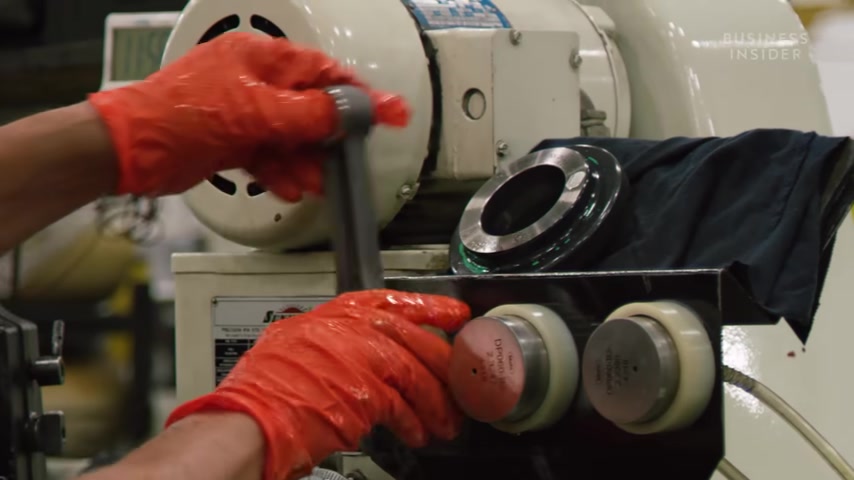

After inspection , some heads go through a milling machine which creates an airtight seal for the combustion chamber .

After a thermometer measures the surface finish of the head .

Then a worker installs the valves and springs .

These can compress and expand upwards of 50,000 times per hour to regulate the pressure inside the combustion chamber .

So proper assembly is crucial .

Once the valve spring pressure is checked , the cylinder head is tagged and set on a shelf to await transport to the engine block .

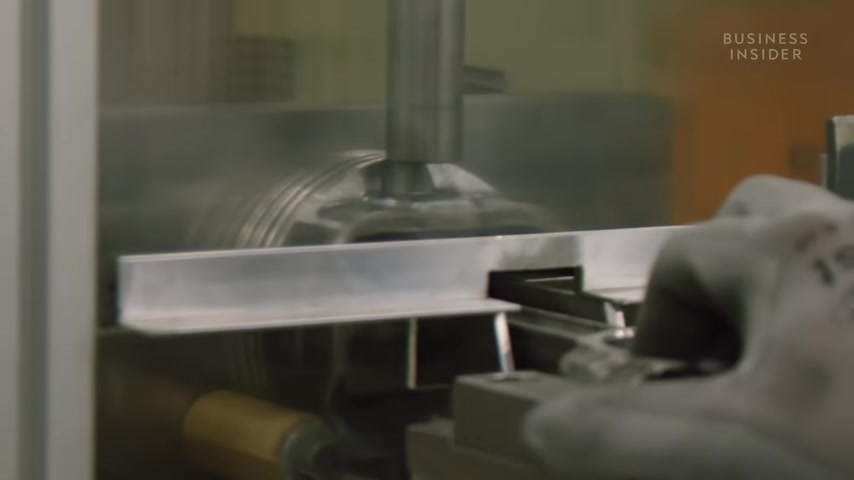

At another station , the crankshaft is balanced even a slight wobble in the way it spins and it can damage the engine here .

The crankshaft is balanced , it's assembled in a cradle that spins 5 to 600 revolutions per minute .

A computer analyzes the movement and tells the worker where and how deep to drill to balance the weight and the process is repeated until the component is perfectly balanced .

Once it's balanced , a worker measures the crankshaft with an air gauge to make sure it's within blueprints , predetermined tolerances here .

An air gauge measures the roundness of the connecting rods in microns about 1/50 the size of a human hair .

Then they are sorted by weight before making their way to piston assembly .

Before both components can be put together , rings are added to the pistons .

This creates an airtight seal in the engine cylinder .

The piston is placed into a machine that will marry the connecting rod and piston above it .

A pin designed to connect the two components is suspended by a magnet .

The connecting rod is heated to about 600 degrees to expand the metal .

Then it's placed inside the piston and the pin connects the two components .

Now the engine can finally be a symbol .

First , the crank shaft is bolted onto the block .

Then the piston is pushed into the cylinder using air pressure .

The oil pan is bolted on and it's sent down the line where a robot bolts the cylinder heads to the block .

During this five minute process , it torques all the bolts down on a second pass .

It relaxes the bolts , then it torques them down again .

In the third and final pass .

The block continues down the assembly line where workers add the top end components such as rocker arms push rods and valve covers which regulate the pressure inside the combustion chamber .

This stage requires close attention to detail .

Blueprint makes a wide variety of engines where components can vary the correct rocker arms or push rods have to be installed on the appropriate engine .

If not , the engine may fail inspection or fail to work altogether .

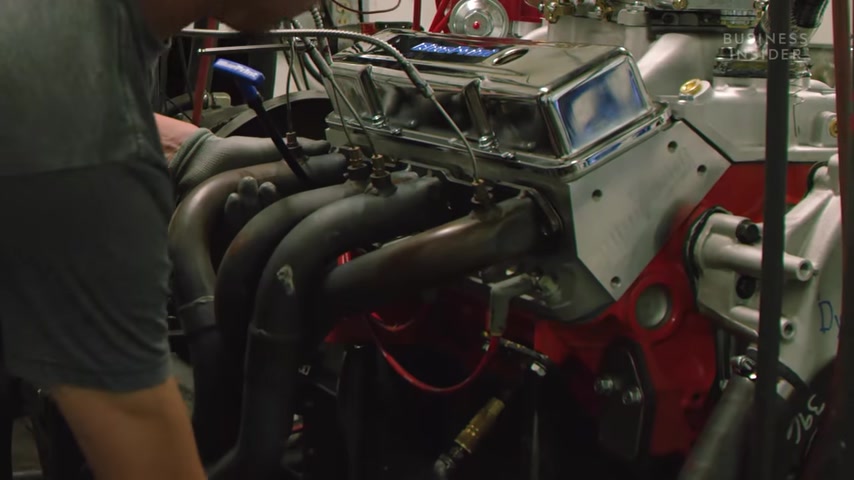

Once the engine is built , it's sent over to one of four dino testing bays here .

The engine is installed into the dynamometer as if it were a car , it's then fired up and put through its paces to make sure it produces the advertised power .

If the engine passes the test , it's bagged to protect the components and packed into a crate before leaving the manufacturing facility .

Are you looking for a way to reach a wider audience and get more views on your videos?

Our innovative video to text transcribing service can help you do just that.

We provide accurate transcriptions of your videos along with visual content that will help you attract new viewers and keep them engaged. Plus, our data analytics and ad campaign tools can help you monetize your content and maximize your revenue.

Let's partner up and take your video content to the next level!

Contact us today to learn more.