https://www.youtube.com/watch?v=xatHPihJCpM

Why Car Companies Still Spend Thousands On Clay Models _ Cars Insider

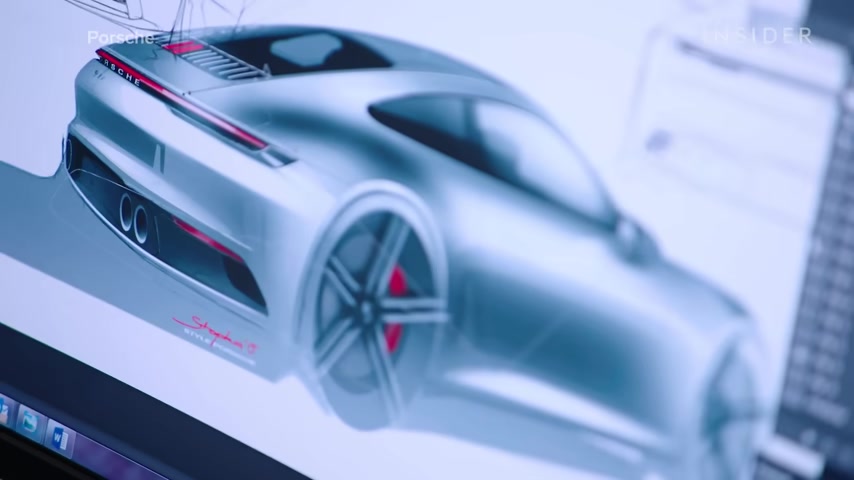

Every automobile you've ever seen once started as a full size carefully sculpted clay model .

Constructing these models can cost automakers hundreds of thousands of dollars per vehicle with major advancements in 3d imaging and virtual reality technology .

Why are automakers still investing so much money in giant hunks of clay to design their cars ?

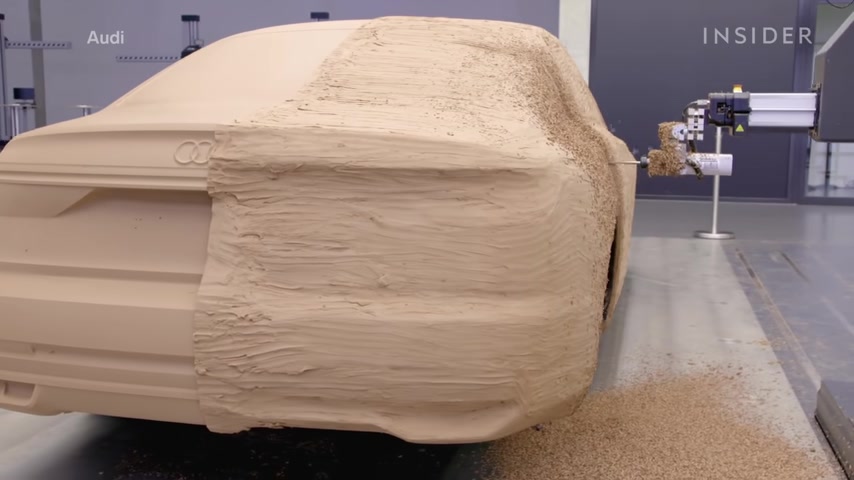

Well , typically inside a clay model they have um it's just usually a steel frame with , with your wheel hubs attached to it .

And on top of the steel frame , it will um get , get blocks of foam glued to it .

And then from there we'll pack , you know , 1 to 2 inches of clay on that , which will be a machine um which then we start sculpting on or or or refining the design from there .

The details vary based on how intricate of a model it is still a full size clay model may feature $20,000 worth of materials and the hours of labor contributed by digital designers , sculptors and milling by C N C machines add up depending on how many adjustments are made to the model .

It can take a couple of years to finalize the origins of clay modeling can be traced back to General Motors in the 19 thirties , Harley Earl , head of G M styling studio was the first to turn sketches into full scale models using malleable clay .

It changed the industry by how much it simplified and sped up the design process .

Designers could now visualize shapes and forms that were difficult and time consuming to create in steel .

But in the 21st century , the age of all things digital , why is clay modeling still worth it as much as you can do on a screen ?

Digitally ?

Mathematically , it's still in essence a two D image .

So at some point in the process , very early on , we need a 3D image that we can see , we can touch .

Uh and we can evaluate proportion .

It's very difficult to evaluate proportions of a car on a screen .

And the thing is with the 3D model , you can't lie , there's no cheating .

It is what it is , what you see on a on the on the tube or on the screen .

Uh It might look great even in V R for example , but when you mill it out , there's always a lot of surprises .

For example , certain lines , you know on a on on a digital module , for example , they may look sweet , but when it's milled in full size , they might hang and the the proportions might look look wrong .

Like I say , you can't lie with 3D clay models can also be useful for aerodynamic testing in the wind tunnels where engineers evaluate a car's drag or how easily it passes through the air around it .

They're the perfect time saving tool .

Well , ultimately , you need to , to lower the drag coefficient , you know , particularly in an electric car , you know , the lower figure , the better , obviously , it's more efficient .

And the thing is with the wind tunnel , it's very expensive to rent per hour .

It's 1000 thousands of times sometimes .

So we do work on a clay model in the wind tunnel .

So we can quickly implement changes because time , time is money basically .

And al although we have computer models for a Dinas , we still need to double check to see if you can be 100% sure .

Perhaps most importantly , what clay models reveal that digital imaging doesn't is what the vehicle will look like in natural light .

One of the crucial tests is taking it outside where designers can see what the car will look like where it will actually be driving .

It's here that they can see how the sun bounces off of its curves and whether it looks like they imagine or just plain wrong .

This doesn't mean clay models are an ancient design method that hasn't changed decades ago when the entire model had to be developed by hand .

It could take weeks upon weeks to create a model to begin working with and testing today with C N C machines and data driven systems .

A detailed model can be milled overnight for sculptors to begin working on just like the entire car industry .

It's evolved to be faster in our design process too .

Like we make many variants quickly in data , in digital data and quickly review N V R um every single week .

Um But whenever we need a validation , we always mail it out again in play overnight and check it again .

If , if it needs some hand work , we do it quickly .

Despite how much quicker computers have made carving whole cars out , there's still an area where human modelers have the advantage , finesse .

Sometimes a detail on a car's body may need to be changed as little as a millimeter and edit like this can be tedious .

But using the malleable clay allows designers to visualize and make multiple changes with real world proportions .

Something a computer rendering can't compete with .

Even if digital technology continues to make car design less labor intensive .

Only clay models finished by human sculptors will help car companies achieve what they're aiming for .

Are you looking for a way to reach a wider audience and get more views on your videos?

Our innovative video to text transcribing service can help you do just that.

We provide accurate transcriptions of your videos along with visual content that will help you attract new viewers and keep them engaged. Plus, our data analytics and ad campaign tools can help you monetize your content and maximize your revenue.

Let's partner up and take your video content to the next level!

Contact us today to learn more.