https://www.youtube.com/watch?v=AWiyreFFt-Q

Which Wire Connectors Should You Use

How's it going ?

You guys , it's Scott with everyday home repairs and when it comes to D I wires and doing electrical work around their house , why do I say that a wire net is the good option .

The ideal pushin connectors or just a push in connector is the better option .

And the wa lever net is the best option .

I'll review all that and we'll go through three different areas .

We'll start off by just looking at the construction and how do you use each of these ?

That's a big part of the overall good , better best assessment .

But we'll also talk about price because there is quite a range across these three different wire connectors .

And then we'll finish off with basically , what did you say ?

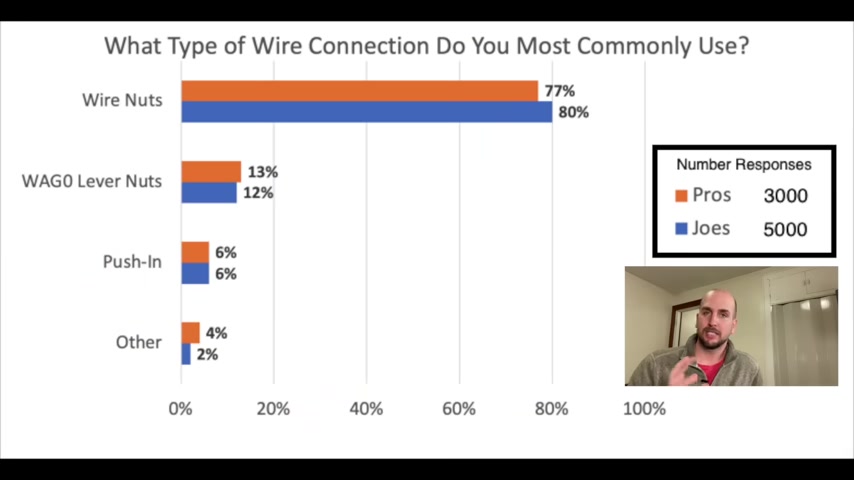

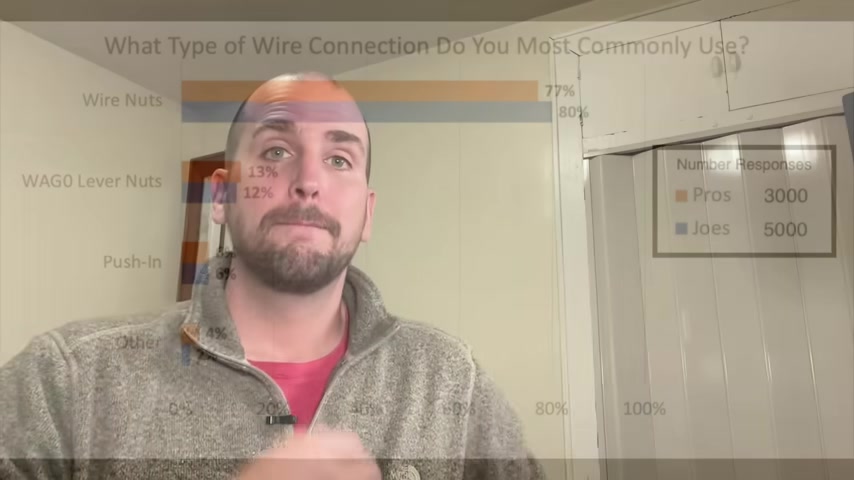

So we received over eight 1000 responses .

5000 came from Joe's , right , the D I wire electrician and 3000 came from quote unquote pros , the licensed electricians .

So with those results , we can see what is currently being used right now from the D I wire to the licensed electrician .

And are they similar or are they different ?

So let's jump in looking at the construction of each and also how do you effectively use them ?

So first up , we'll do the wire nets and we'll talk about the push in connector from ideal .

And then the 221 lever net wire nets , wire nuts have a range of wires for which they can work .

This is a wing wire net from ideal and it can work from the small end which would be 2 18 gauge wires to the high end , which would be 3 12 gauge wires here .

For this example , we have two wires and there will be 14 gauge .

So it's right in the heart of the use case for this wire .

So it's a perfect match .

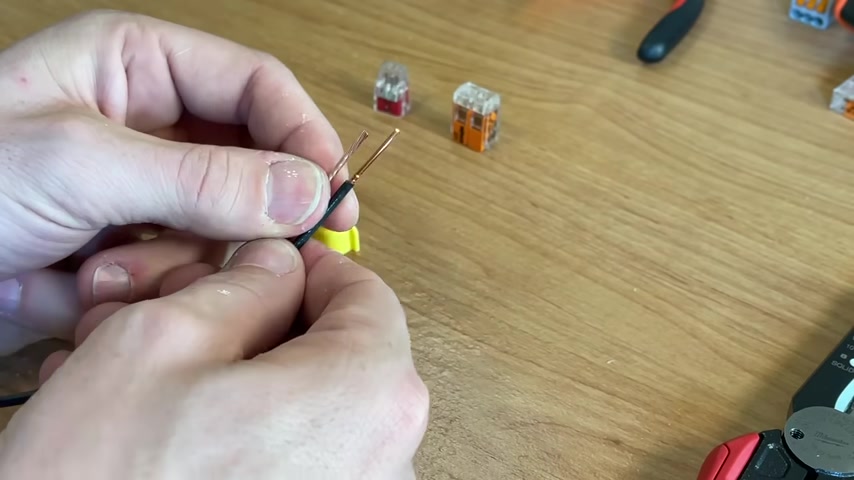

Now , what this example demonstrates is an issue that I see a lot and that is where you would have Rome with solid core wire .

So that'd be a 14 gauge solid core going to like a light fixture with ST a stranded 14 gauge .

So you need to bring these two together .

This will be easier because I have the freedom of just holding the wires in my hand .

But usually you're on a step ladder overhead , holding the light .

So this can be a little bit of tricky .

And the problem is is if you put these two together and you do not pre twist , you're gonna let the wire not do the twisting , which usually manufacturers recommend .

But some people pre twist and you lead with the solid core .

So if the solid core is slightly longer than the twisted pair .

You put that within your wire net , you start your twisting and usually what you're looking for is for it to bite and then for you to get two rotations of the wire outside of the wire net .

Now , what the problem is here and what the air can be is , hopefully you're doing your pole test to test this out .

But a lot of people once this caps on and you felt it , you felt it winding within the wire net , you feel like it's good to go .

But if you've done this for any amount of time , you know , this is a pretty classic failure .

And what happens is that that stranded piece is not being securely fastened within there .

So if we were to take off the plastic and look basically within the threads inside , this is what's happening , that solid core is actually going through the the threads here of the wire net .

So this is what's internal to the wire net if you take the plastic off and then the strands here is really just kind of snaking around and only getting one or two rotations .

So if I undo that you can see how weak of a connection this is where the strands are just barely on there , then in the pull test , the strands will pull right out even though the solid core is still the teeth of the threads here is still within the solid core holding it within there .

This happens all the time and , and it's almost about one out of three light fixtures that I open up have a very loose connection .

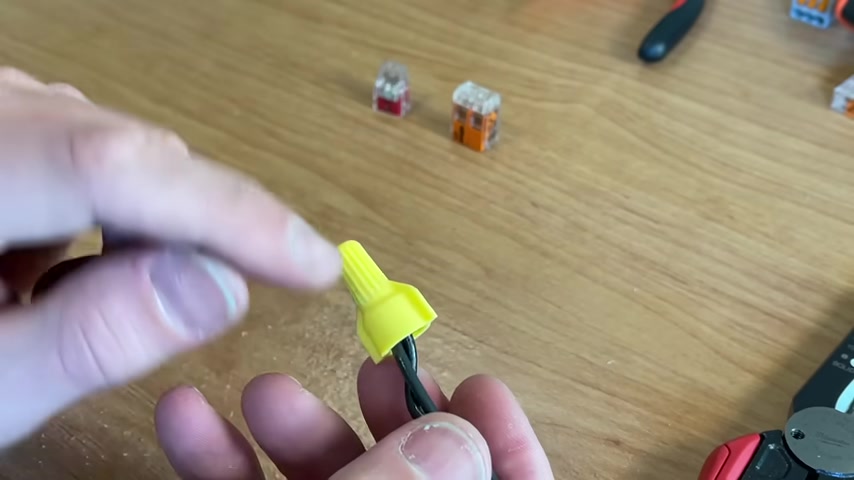

So the wire net can be a very effective option .

And it's been around for so long and it is very much proven .

But the main reason I'm saying this is a good option is because from a diy standpoint , you're only doing one or two projects a year and there's too much opportunity for air here .

It's all about the installation .

It can be a very effective connection , but there is a lot of opportunity for air .

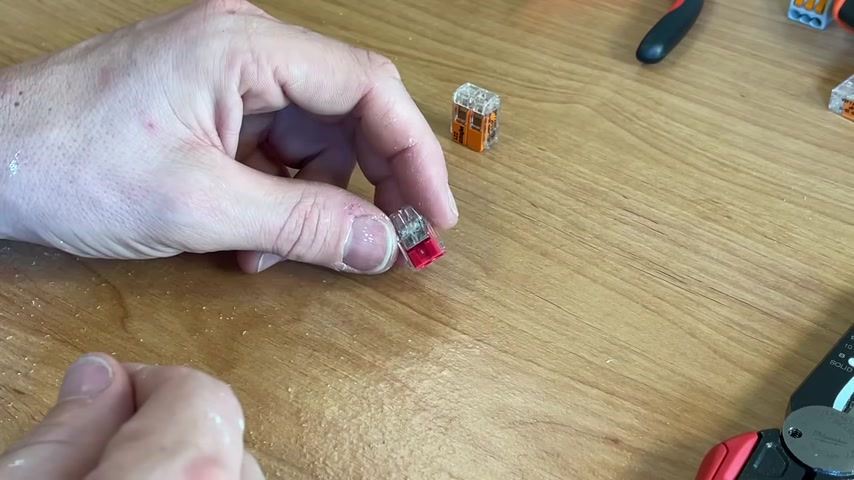

So let's look at number two and that is just a push in connector with the same application now pushing connectors many of the videos many times in the past the 14 gauge , pushing at the back of a receptacle , I am not a fan of and I have said many times not to use that .

So the big design difference that makes me more of a fan for this ideal push in is if we take our solid core wire usually stripped to about a half inch and we insert that in and we can see it's secure within the pushpin , then we take our , our braided strand , making sure that the braids are not frayed off and they're together .

So you might need to twist it slightly and then we can press that within there .

So then we also see that the strand is seated , it passes the poll test .

So that big difference is the transparency through housing just being able to see the wires themselves and confirm that they have fully seated within the pushing is a huge difference comparing to the push in here on a standard receptacle , not a fan of these , but these pushing connectors .

I do think the opportunity for error is significantly less with these compared to wire net .

And that is almost solely why I'm giving it a better rating compared to the good of a wire NT .

So for D I wires push ins , I say would be the better option .

And the only other thing I'll show you is I actually did remove the internals of one of these .

So what this is showing you is how they secure .

So there's just these tabs that will be pressed out of the way when the wire is introduced and then it will , that is what's holding it in , it bites into the copper during that pole test and it then it presses it down onto the bus bar .

So this bar here that goes across these three different tabs .

It's actually the bus bar and that's what's responsible to tying all these wires together .

So that's the internals of the push in ideal connector .

And since I know there will be comments coming in in terms of why I wouldn't like push ins on a receptacle .

But I'm saying that the the ideal pushin connectors are a better option than wire nuts is because on a receptacle , you have the screw terminals that I would prefer a clockwise j hook connection opposed to using the pushin connectors .

And even better .

I prefer a commercial grade or spec grade receptacle with the plates here where you can do a back wire .

So a straighten strand of proper and then tighten that plate down and use the back wire feature .

So that is a little more information on why I don't like push ins on receptacle .

But I'm saying that these are a better option and you're just gonna get a more consistent and secure install with a push in connector for my deal .

If you're ad I wire , that's not doing this on a daily basis compared to a wire dev .

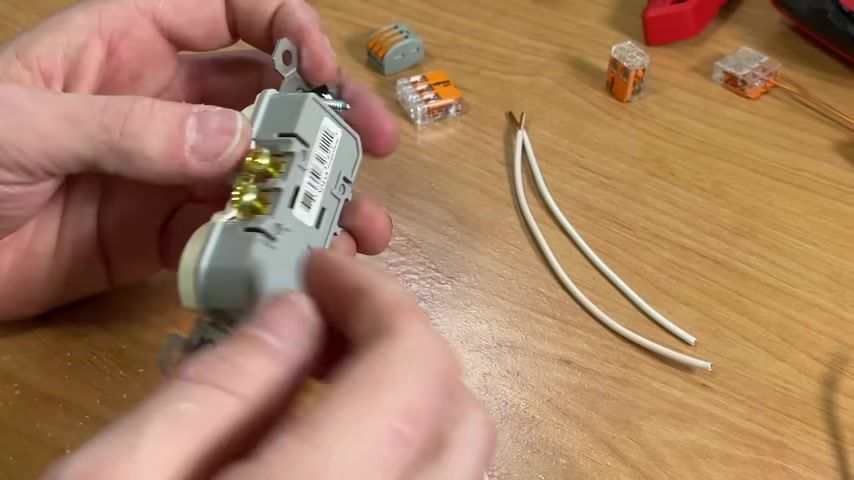

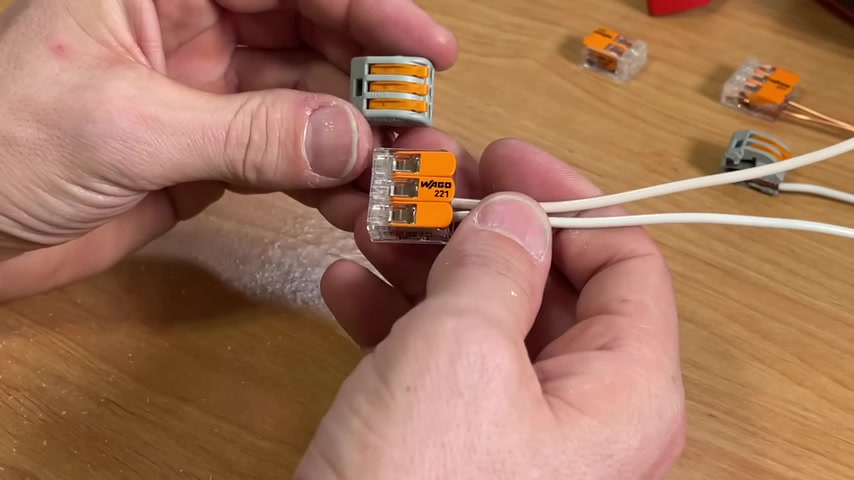

But there is the best option and that is a wa 221 lever nut .

Now , you might know of Wao Laver nuts from the 222 model , which is right here , but let's dive deeper and take a look at these .

And why I'm saying this is the best option for D I wires doing electrical work .

I'm gonna focus on the 221 but the 222 is a little thicker .

The levers are a bit harder to pull open .

And the most in the most important part , it's not transparent .

So that's why I prefer the 2214 D I wires with the lever net here .

All you have to do is just pull the levers up for the number of wires that you have .

And we'll do the same application where we have a 14 gauge solid core .

We'll insert that in till it hits the back wall .

Close the lever that will secure the wire .

We'll do the same for the stranded 14 gauge close lever .

I mean , just like the ideal , we can see that those wires are fully seated in here .

So for me , the 221 easily is the best wire connector because for D I wires , we're not doing this very often .

We want to do it safely and securely .

And the lever nut on the 221 is the easiest to operate where you're going to get consistent connections which are secure and safe within your electrical boxes .

Now , you might not have seen these because at least in my area , they're not readily available at Lowe's or Home Depot .

I can get them at ARDS , which is a local home improvement store , but you can also get them online .

So down in the description , you'll see the Amazon links to the 221 and also include the 222 just for your reference .

But be careful when buying off Amazon , there are a ton of knockoff brands that look like these , but they are not made by wa and I don't necessarily recommend any of those even though I'm sure they are cheaper .

So let's talk about price .

So you'll see here , the cost really didn't come into a factor when I gave the good , better best rating because the pricing is actually opposite of that .

Your cheapest is going to be your wire notes depending on where you get them .

And also the quantity that you buy , you're expecting to pay between five and 15 cents per wire .

Not next would be your push in connectors .

The ones we looked at are made by ideal Wao also makes push in connectors .

I really like a new one they got coming out in the summer which is the 2773 .

So look out for that one , it looks pretty nice , super compact .

The cost is gonna be substantially more compared to wire notes at 15 to 25 cents per connector and then finishing out with the wa 221 again , depending on where you get them in the quantity , you're going all the way up to 30 cents to about 55 cents per connector .

Substantially more .

And technically a WAO connector could be 10 times more expensive than a wire net just depending on which one you're getting that is substantial .

But for AD I wire , this is what the the mindset of AD I wire , the amount of projects you're doing are limited .

And I think the peace of mind and safety is easily worth the substantial more cost per connector .

But what did you guys say in terms of what are people using currently ?

And the two different surveys were for the D I wires , the Joe's and the licensed electricians of pros .

Now , could I be confident that only licensed electricians answered the survey for pros and only D I wires for Joe's .

No , absolutely not .

And maybe in the results that kind of comes out here because we see it's pretty much a wash between the two pros versus Joe's the legacy and familiarity of the wire net pulled through .

So 75 to 80% of people use wire nuts .

So they are still very commonly used probably because of the cost .

And again , just that legacy of being used for so long now , Waco surprised me and came in number two at 12 or 13% of people use those .

And this is most commonly .

What do you use , most commonly , not exclusively but most commonly .

So I think Waga is really getting some traction and I was a little surprised there are some licensed electricians that seem to be using Waga lever notes as well .

Comment down below .

Uh Either way , what are you guys currently using ?

And why do you , do you follow the same thought process that I outlined here or do you have a different opinion ?

I always welcome you guys's feedback and that actually generates a lot of the new content coming out .

But back to the use of push ins we're at about a 6% of push ins , which is interesting because pushings are very readily available .

You can get them at any lows , any Home Depot , they're out there everywhere .

So I'm surprised that they're actually lower because Waga are way less available .

So people are really having to go out of their way to get the Wagga lever nuts and must really like them .

And then there's some miscellaneous , you know , 2 to 4% use others .

There's a lot of different things on the market .

So there are a few other things being used for wire connectors .

But that's it good .

Better , best wire net , good cushions , better waga lever nuts .

Specifically the 221 is the best , agree or disagree .

Let me know down in the comments .

Also , you'll see in the description , you'll see links to all these different connectors just in case you're interested .

And for the D I wire that does electrical work multiple times per year , I do recommend getting maybe a multipack of WA 0221 with two slots , three slots and five slots .

I get , I think that covers you .

You'll have the kit and the if you ever need to replenish that supply , you just get the specific connector that you need and then fill up the kit .

That's my recommendation for those that are doing projects on a fairly regular basis around their house .

And if you haven't already , don't forget to subscribe to the channel before you take off .

We have videos like this coming out multiple times per week to help you with repairs and improvements around your house and we'll catch you on the next one .

Take care .

Are you looking for a way to reach a wider audience and get more views on your videos?

Our innovative video to text transcribing service can help you do just that.

We provide accurate transcriptions of your videos along with visual content that will help you attract new viewers and keep them engaged. Plus, our data analytics and ad campaign tools can help you monetize your content and maximize your revenue.

Let's partner up and take your video content to the next level!

Contact us today to learn more.