https://www.youtube.com/watch?v=cFSsiB-PrYw

How Dry Ice Is Used To Deep Clean Cars _ Cars Insider

Uh , Scott Ailes with Dry Nation .

So today , I'd like to show you the step by step process that we go through in dry ice cleaning .

So there's a number of things that are unique about dry cleaning .

But number one , we're not using water .

So when we're done , we're not cleaning up water spots and we're not trying to dry things .

If you can see the dirt , we can clean it .

So there's a lot of places where you might be able to see that dirt , but you can't physically get to it with any tools or brushes or devices .

And you know , we can , we can clean that in the deep recesses of your car that you might not have been able to before .

It's like when the car rolled off the factory line , you've cleaned it back to that condition .

So what , what we're just getting started .

We're trying to identify the method of what we're gonna attack first .

When we put a car on the lift , we always wanna make sure and pull the wheels off so we can inspect the inner wheelhouse area .

We use a torque wrench to break the lug nuts loose .

We also like to consider , depending on the customer , if they want us to remove the inner wheelhouse liners , which are typically plastic to see if they want us to clean behind there .

So once we have the car in the lift and we're prepped , we're , we're then moving our attention toward the compressed air system to make sure that we've got all of our drying and cleaning systems for the air system in a and then we're gonna load the machine with the dry ice so that we're prepared to , to blast .

And so the first thing we try to do is get the wheels out of the way .

We have four wheels and we'll just take those one at a time .

You know , we'll look for tar , we'll look for adhesion , uh remnants from old wheel weights which are totally a pain to remove and we make that pretty easy .

Uh And then we just , we'll clean the wheels inside and out .

The three settings are , you've got pressure , which is P si that you're all familiar with .

There's pounds per minute and then you've got size of particle .

So those are the three things that you can adjust .

But for the first time , we can actually choose the size of the particle .

So it enables us to be able to do delicate things in the same area of things that might be aggressive .

Uh Previously , you were putting those delicate items at risk with a large particle size when we're starting the project , we're always looking for the dirtiest area .

First .

We like to get the hard stuff out of the way so that we get to those surfaces or those coatings that we're trying to remove that are easy .

Then it makes everything go smoother because you're not double cleaning .

So you'll notice as I'm cleaning that the gun is never static .

It's always moving , it's always constantly moving .

And the reason for that is we have the risk of a concentrated one oh nine negative degrees on a particular substrate or part of the car that you could damage in one spot .

So I'd like to take a minute and explain how this actually works .

There's really three things that are occurring .

You've got kinetic energy which is driven by the P si of the air system .

You've got cold temperature one oh nine degree negative that causes things to shrink .

So they lose adhesion .

And then you've got the actual thermal expansion of a solid chemical going to a gas .

So that's 800 times its original solid size .

Those three things work very well together to remove this dirt in a way that you probably never seen before .

There's a lot of technique opportunity here , right ?

Because in a sense , this is , this is a bit of a , an artist's effort at an industrial job .

If you will , I found it to be helpful for me to function in a circular pattern .

So that I never have any hard lines that the circular pattern gives me the control that I feel comfortable with .

There's really nothing that's more fun in this process than doing bare aluminum .

You really can't hurt , bear aluminum .

And so in that case , you can crank it up , it's more efficient .

You feel better about it and , and it's , it's very satisfying to the eye .

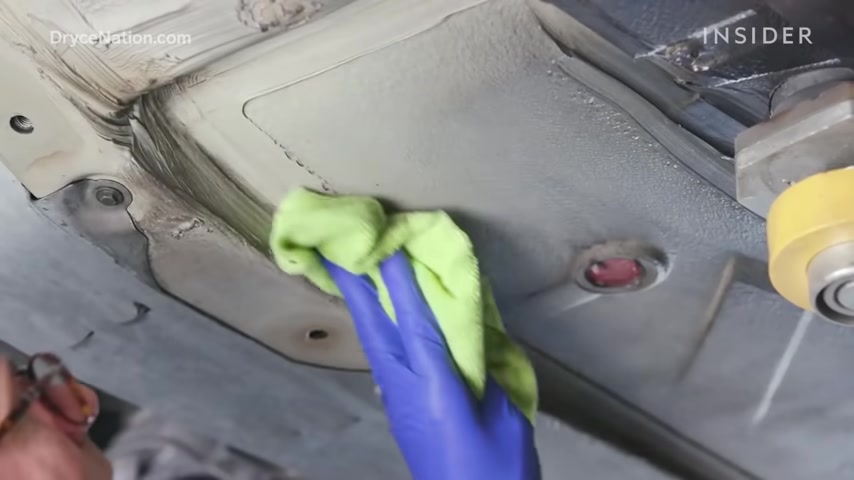

So once we've removed those really difficult grimy , uh , surfaces , uh , we , we do move into a combination of handwork and fine detail , dry ice cleaning .

People presume that what we're doing is a magic wand and we just wave at once and we're done and that's not true when we have surface rust .

Uh , we do integrate and uh a fair amount of hand work whether it be all purpose cleaners , white erasers , steel wool .

Uh , definitely , we , we do use hand work at the point in time that we , we believe we've finished with the underside , we'll bring the car down three or four ft and then we'll look at the top of the suspension in the wheelhouse areas and then we'll notice , ok , we got some more work to do here .

So once we clean the underside of the car , we bring the car down on the lift and we have an extra wide lift so that we can open the doors , get the floor mats out .

We can do the interior vents , the door jams the engine bay , the trim and and we don't abrade the service and we'll do what takes somebody two hours in 10 minutes .

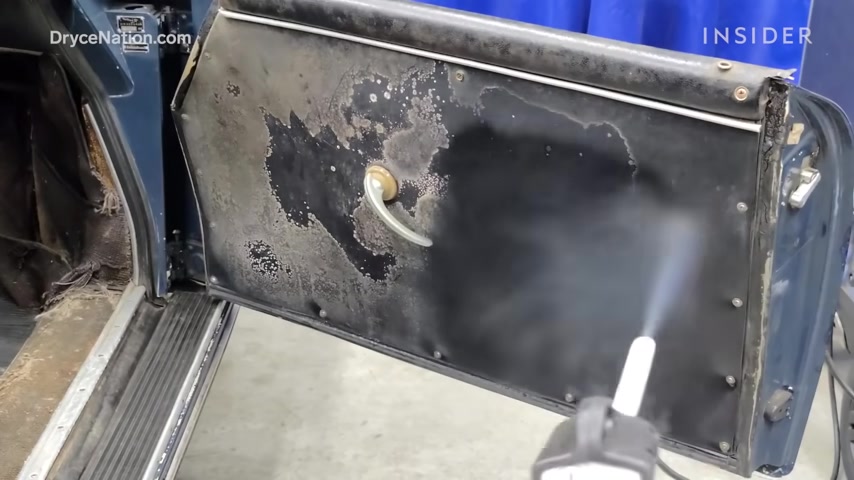

So we were fortunate enough to receive this 55 Porsche speech and it literally is a barn fine .

What you're seeing here is me trying to see if I can remove this crazy thick mold .

That's 30 40 years old off 60 year old vinyl .

That mold was so thick , it would stop your fingernail .

This was a big moment for us and the end result is we will apply some all purpose cleaner at the end and we wipe off the final film from this panel , but it just turns out spectacular .

So we don't add to or remove any CO2 from the environment .

So we're neutral and we don't use water , which means that we don't rinse chemicals down a drain into any sewer systems or into drain fields .

So , from an environmental standpoint , by far , it is absolutely a better cleaning solution than using water and chemicals .

The driest cleaning world could be considered the highest level O CD crowd .

Think about the underside of a car and the intricacies of every component .

There's a lot of surface area to all of these parts and pieces .

Don't think that it's going to be easy .

But the satisfaction factor for those that care about the way their assets or their artifacts look is at the highest level .

So it's , it's worth the energy

Are you looking for a way to reach a wider audience and get more views on your videos?

Our innovative video to text transcribing service can help you do just that.

We provide accurate transcriptions of your videos along with visual content that will help you attract new viewers and keep them engaged. Plus, our data analytics and ad campaign tools can help you monetize your content and maximize your revenue.

Let's partner up and take your video content to the next level!

Contact us today to learn more.