https://www.youtube.com/watch?v=QIwpNKfy4sg

Why Damascus Knives Are So Expensive _ So Expensive _ Insider Business

This is a Damascus knife master blade Smith , Zach Jonas is twisting a fusion of steels to make one of its trademark swirl patterns .

But these unique swirls are more than just decorative , successfully welding dozens or even thousands of steel layers , create some of the strongest and sharpest knives .

Money can buy .

What starts as individual layers of two different alloys transforms into this a seven inch chef's knife that retails for $700 .

Some of Zak's knives cost $5000 and commissions can reach well over $17,000 .

So how are swirl patterns made from steel and why Damascus knives so expensive ?

What people tend to notice right away when looking at Damascus is that visual pattern ?

And it ranges from uh very , very bold and big layers to very , very fine and shimmery layers .

And you're gonna see that pattern jump out at you and you're gonna see the way the light plays off of it and it's gonna shimmer and look almost holographic at times .

The blade Smith in community refers to this effect as a Chato or the shine of a cat's eye .

Aside from the striking pattern quality Damascus knives are known to be hard but flexible and able to maintain a sharp edge to make .

Damascus steel .

Zak starts by layering two different kinds of high carbon steel , managing the layers means more work for the smith .

And while high end mono steel knives may perform similarly .

Damascus knives are coveted for their striking appearance in the craftsmanship required to achieve it .

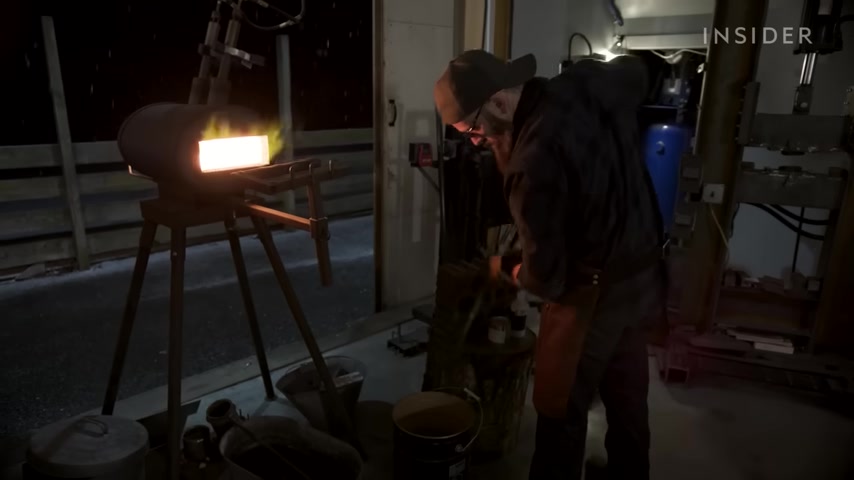

After tacking the layers together , Zak puts the stack in the forge and heats it to about 2300 degrees Fahrenheit .

He needs an experienced eye to judge when the steel is ready because it's at risk of breaking off the handle while the layers are not yet forge welded together .

Zak needs to consider the kind of pattern he wants to make before he can begin forging .

A bold pattern means fewer layers and a more intricate pattern can require several 1000 and working with so many layers to achieve his intended design means lots of things can go wrong out of thousands of hammer strikes a single blow in the wrong place , can ruin the pattern even when the pattern is done to perfection .

Zak has to forge the steel into a knife without distorting the design .

And if he forges the steel when it's too cold , it can crack and he has to start over which for Damascus steel can mean losing weeks worth of work .

Once he forge welds the steel into a long bar , Zak can begin folding over the layers the layer count has the most effect on the price .

The more layers , the more folding and work for Zak , which means a higher price point .

The pattern on this particular knife called Texas wind has only 45 layers , which is why Zac sells it for just under $1000 .

But his more expensive knives can have 5000 layers and that can take a month to complete giving it a higher price tag .

You can see I'm twisting the steel with this wrench .

It's got to be real hot .

If it gets too cool , the layers will want to shear and come apart and then the piece is trash , keeping track of the re that I'm twisting at counting as I go , this technique is specific to twist Damascus and it creates star like patterns on the steel , too much twisting and the steel will want to shear .

But the tighter the twist , the more dramatic the pattern and that'll do it .

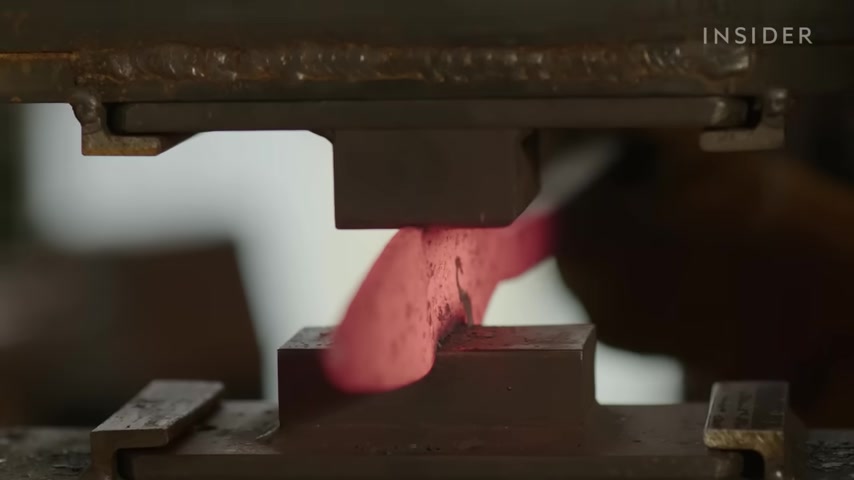

When Zak is making a standard Damascus wave pattern .

He continues to work on elongating and thinning the bar using a power hammer .

Zak's larger power hammer cost him $20,000 but that's just a drop in the bucket .

He spent at least $100,000 on specialized machinery , but this large investment allows Zach to produce high quality Damascus knives .

Zack forges the tip of the blade , he cross checks it with his template to ensure the knife looks exactly as it should .

Now it needs to undergo a metallurgical change , which is called heat treatment .

And this part is hardening .

And without doing this , the thing might be shaped like a knife , but it won't behave like a knife .

It won't take an edge , it won't hold an edge .

So the heat treatment is really , really a critical process and it determines the metallurgy and therefore the performance of the finished knife .

But it's the quenching that makes or breaks the knife .

Sometimes a blade will fail in the quench by cracking or warping , irretrievably looks like the blade came through the hardening process really well , it's straight , it doesn't have much warping .

Little warps can be corrected .

And I can see that the scale has blown away from the surface of the steel here which tells me that the steel has contracted and become hard and that's what I was looking for .

So now this is ready for finished grinding and then a handle .

The grinding operation is one of the areas where the skill is kind of most important and most obvious .

And this is one of the things that really drives the cost .

A single slip can , can ruin the piece in an instant .

The handle is also an important factor when pricing the final product .

Some materials like local maple are more affordable for Zach .

But this Arizona Ironwood costs him 10 times as much .

It's also a harder wood than maple and requires more work to shape .

Zak designs the handles so they serve the purpose of the knife .

He makes kitchen knife handles slim but large enough for the chef to have a firm grip , a hunting knife .

On the other hand requires different properties .

It might be used with cold or wet hands which can cause them to slip .

The final step in creating a Damascus knife is the etching which makes the pattern bolder to the eye once dipped in the etching mixture , one of the alloys oxidizes and turns darker while the other alloy resists maintaining its color .

Now , the Damascus pattern is revealed , but Zach isn't done yet .

He needs to assess the quality of his creation .

Let's test the edge and I use paper for this .

This is a simple test glide through with no problem .

This knife is razor sharp with no dullness that needs adjusting .

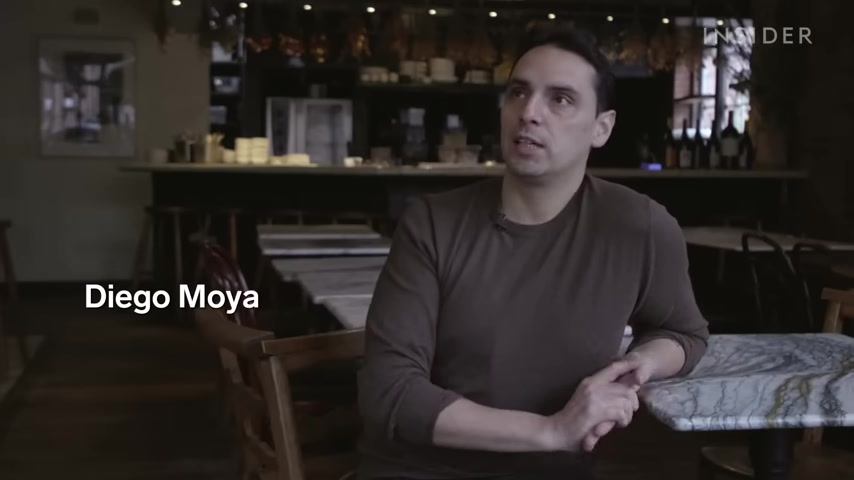

It's ready to sell to chefs like Diego Moya Diego has been a chef for 27 years and focuses on vegetable cookery .

I've had some sharp knives , but this one kind of out of the gate just feels like it .

It glides through without any resistance at all .

It's pretty amazing .

You basically , it just does exactly what your arm wants it to do .

You don't have to fight it .

He's using a 10 inch chef's knife made by Zach , which costs $1200 .

I think the experience is one of effortlessness .

I think you just forget that you're using a knife .

And I think that when you forget you're using a knife and you use your arm to produce the cutting motion .

That's pure bliss .

For this kind of experience , you have to , you have to pay the price .

Zak's buyers typically know the work that's gone into the knife they purchase and the skill level required to make a quality Damascus knife .

Zak is one of the fewer than 200 master Blade Smiths designated by the American Blade Smith Society to earn the title , they must successfully produce a Damascus blade with a minimum of 300 layers .

The blade must be strong , tough , sharp and balanced .

In Zach's case , he had to take the test twice before getting the master smith title .

The knife performance test includes cutting through a two by four and even shaving hair off his arm , but it was the presentation test that set Zak back because of a 10 degree misalignment in the handle since becoming a master smith .

Zak has continued to evolve his skills in Damascus making one of his current projects might sell for over $100,000 if it's officially commissioned .

So this is a project that I've been working on designing for quite a while .

This is a very elaborate Middle Eastern sword , a type of Mitar .

This is a rough ground blade that I've forged out of 1500 layer .

Damascus .

The demand for Damascus knives has created a market for fake Damascus where manufacturers imprint the swirl patterns on the knife and sell it at a more affordable price .

You can get a Damascus knife for 30 bucks , but it will not cut anything for you .

There's definitely a growing demand for Damascus Steel .

Um when I started out knife making , it was not super well known and I've really seen it myself in the last 15 years or so .

Uh as , as the cultural awareness has come up and people really understand what they're looking at .

Are you looking for a way to reach a wider audience and get more views on your videos?

Our innovative video to text transcribing service can help you do just that.

We provide accurate transcriptions of your videos along with visual content that will help you attract new viewers and keep them engaged. Plus, our data analytics and ad campaign tools can help you monetize your content and maximize your revenue.

Let's partner up and take your video content to the next level!

Contact us today to learn more.