https://www.youtube.com/watch?v=ICM9E3ocwmE

CONSTRUCTION TECHNOLOGIES THAT HAVE REACHED A NEW LEVEL

a modular septic tank is a very practical solution for standalone sewage and wastewater systems .

This system consists of a perforated , flexible pipe , a special expanded polystyrene aggregate and a geo textile mesh .

Keeping things simple is the key to success .

First of all , the modules can easily be placed in single file parallel to each other or on top of each other .

In other words , obstacles in the working area are no longer a problem .

Secondly , there are only two lengths , one and three metres , both easily transportable and install even by one person .

And thirdly , the septic tanks are easily scalable for private or commercial projects , thanks to their diameter of up to 46 centimetres .

Connecting the modules is simple by snapping them together .

In addition , they're made from recycled materials , so manufacturers and customers are helping the planet by using them .

Turkey has a strong passion for construction , granting permits for building over 550,000 apartments in 2020 to excel in the industry .

They embrace innovative methods .

For example , this combination of bricks plus expanded polystyrene .

It's the only system on the market that allows you to build in any region of the country without additional insulation .

Exterior walls are a significant source of heat loss , accounting for 20 to 25% of it .

But in this system , both the bricks and the expanded polystyrene act as thermal insulators , so future owners will save on electricity costs .

The manufacturer offers several options in terms of walls , size and thickness , and highlights their durability and additional sound insulation .

Next , a two in one grid .

This will reinforce the soil and allow water to pass through smoothly .

As a result , a grass or gravel area will always look aesthetically pleasing and will not be flooded after a downpour .

The load bearing capacity of 250 tonnes per square metre is enough for parking lots , campgrounds and other areas with a large number of cars .

The manufacturers have also prioritised environmental concerns by using recycled polyethylene for the grid .

The grids are held together by a clip system .

One pallet containing 100 and 12 pieces is enough for about 25 square metres and given the size of today's parking lots , the manufacturers will not be short of customers .

Our selection continues with composite decking for terraces .

This is one of the thickest options on the market , reaching 37 millimetres .

The decking doesn't bend warp or rot .

It also doesn't rust , doesn't absorb liquids , including wine and coffee , doesn't need to be painted or sanded and doesn't contain lead .

The manufacturers have listed all these advantages and more .

The primary material used is PV CU .

It's like PV C , but without plasticizes , so it can even be used in the food industry .

The boards have successfully passed fire abrasion and slip resistance tests , and for added peace of mind , customers receive a 10 year warranty .

All that remains is to choose the right colour and texture .

Surprise your friends with some knowledge .

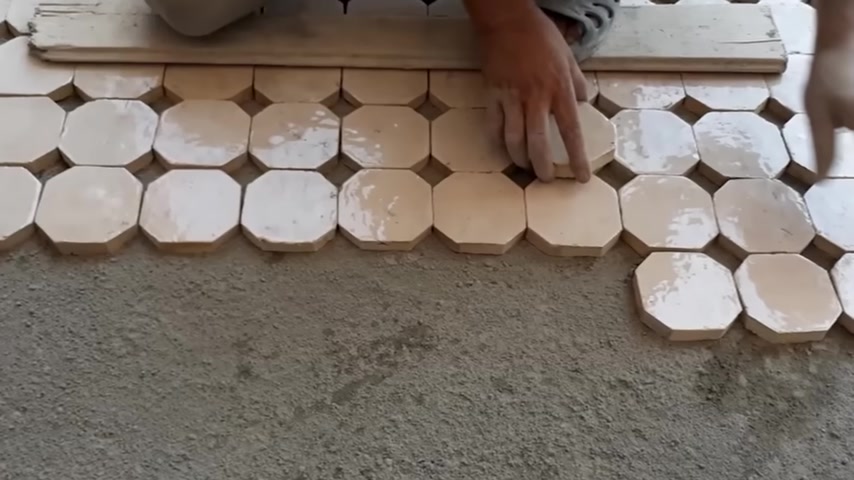

These tiles are called zee .

They originate in Morocco and have been popular since the 10th century .

Originally , they were small and looked like a three by three centimetre mosaic .

Each tile was made by hand from raw clay and painted by hand , so they were pretty expensive .

Today they're much more affordable , as the tiles are manufactured in factories .

But handmade age has not lost its popularity .

In the video , you can see a Moroccan workshop using traditional techniques such as sun drying and baking in a classic kiln at temperatures of 800 to 1000 °C .

There are more than 70 designs in the workshops catalogue , and the tiles are sold not only in their country of origin but also in Europe .

In Mexico , there are unique traditions , too .

At an architecture festival , the public was surprised by an unusual installation that offers a fresh perspective on tete a local material rich in calcium carbonate , commonly used in construction .

Now , te based blocks can be 3D printed .

It's easier , faster and much more versatile than using other technologies .

In addition to this material , cement , lime and water are needed .

The robot squeezes out the resulting material layer by layer like if it were toothpaste , so no form work is needed and anything can be built with it .

At the festival , they made a roof for a small pavilion in 2021 approximately 1.6 million building permits were issued in the United States .

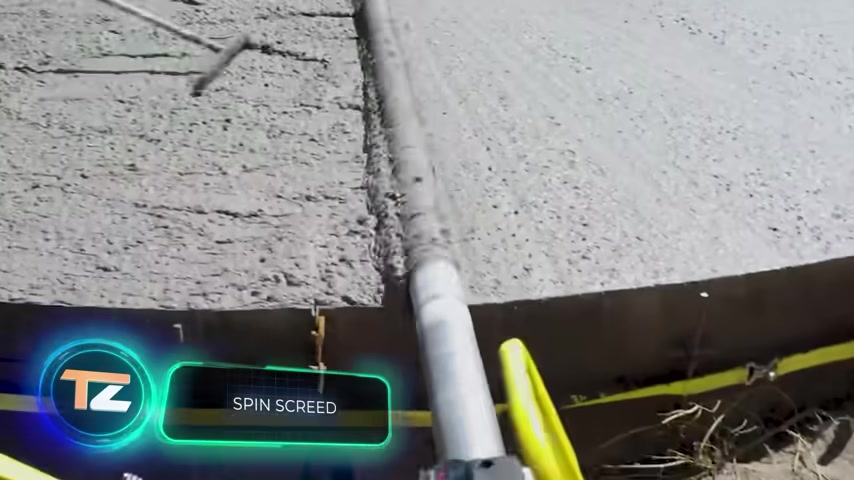

There is a lot of work in the construction area , and it can be done more quickly with specialised equipment such as this one .

It's a simple and effective solution for screening concrete , a rebar acts as an axis in the middle of the future construction .

The manufacturer claims that even inexperienced workers can perform clean and accurate screening .

There are battery and fuel powered versions available , with the latter using a Honda engine .

Roller lengths range from 1.2 to 6.7 metres .

Unlike vibratory screens , it offers higher final quality and a flatter surface .

The two batteries of the electric version can be charged at the same time .

In just 30 minutes .

The price is around $1600 .

Now let's take a look at the advancements made by a major independent precast concrete products company in the United States .

These sections reliably protect water and sewer pipes , including storm drains .

They're available in various sizes .

For example , the type one is 1.8 metres high and the Type three reaches up to 3.6 metres .

The length depends on the customer's needs .

The company also manufactures fully customised versions , including curved sections .

In addition , the sections are versatile and will also be useful in projects involving bridges , pedestrian and service tunnels , subway warehouses and even shelters .

Many shopping malls and office buildings lack visually appealing exteriors .

These modules will make facades more interesting and attractive .

Thin clay tiles are held in place with stainless steel clips , and from the outside they look like real bricks .

There are several design options , for example , for Flemish or English bond .

Four standard shapes are available , too .

The size of a typical rectangular panel is 56 by 37.5 centimetres .

They last approximately 60 years .

The panels are fully assembled at the factory .

Have no glue or resin , are fire rated a one and are no more difficult to install than similar products .

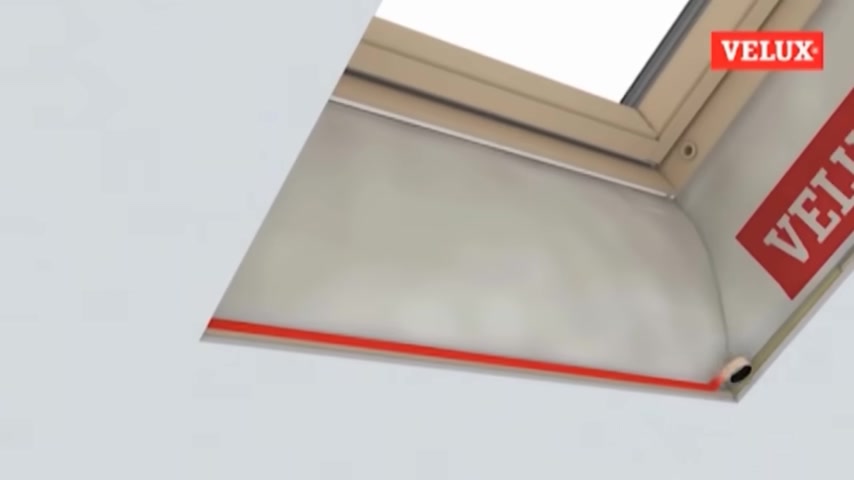

The creators of these new generation roof windows are pushing the boundaries of innovation .

Their windows not only provide excellent lighting and enhanced aesthetics , but also come with top notch waterproofing , eliminating the risk of leaks .

Customers are offered two installation options .

The classic roof level installation or a recessed installation that's 40 millimetres deep .

The minimum angle is 15 degrees .

It can be installed on slate roof tiles , roofing sheets and other materials .

Maintenance is minimal , too , requiring the removal of leaves and debris at least once a year and clearing snow in winter .

The combination of foam insulation cladding and a soft membrane skirting around the perimeter is an advantage for heat retention , and the window is designed not to interfere with rainwater drainage .

Often , a lot of interesting things are installed under wooden decks , from wiring to various equipment to access them , a kind of trap door is needed , a board that can be quickly and easily removed and put back in place .

The simple and effective solar switch lock has been developed for such cases .

The plastic triangles are mounted on screws with extra room for movement , which allows them to be shifted using tools like a pussy knife while at the same time protecting the ball from falling out without being visible .

It's an elegant , effortless and cost effective solution , with four pieces costing around $3 .

Sometimes when workers install something on a metal roof using bolts , it can result in leaks at the joints .

To prevent this from happening , ingenious people have come up with an innovative membrane that's suitable for both future projects and for repair and maintenance work , even over loose rusted bolts and directly over the holes , no torch or adhesive is needed to secure the membrane .

A surface treatment with Primo is all that's required .

The primary material used is ethylene propylene rubber , commonly found in automobiles and window profiles .

The material is elastic , easily adapting to the shape of the bolt and highly resistant to UV rays and frost , enduring temperatures as low as minus 45 °C .

How are rooftops used in your city ?

In Paris , for instance , an exhibition site has set up a 14,000 square metre vegetable garden where you can even rent a portion of it .

Meanwhile , a British company is offering to rethink roofs .

It's willing to take on both renovations and new buildings , and you can not only a green roof but also a blue one .

Rainwater will run off more slowly , so there'll be less strain on drains and storm systems .

You can easily build an orchard , a garden , a recreation zone or something modular .

Other advantages include sound insulation , cleaner air and energy savings .

Due to heat retention , the company is also available for individual repair work , such as waterproofing joints , as showcased in the video .

Another solution for waterproofing roofs and facades , the Ephesus stopper kit .

It is very useful on metal or soft membrane roofs .

The kit allows you to start working right away and consists of three components .

A flexible skirting board with fastening and two sealants .

No prior preparation is necessary .

The system allows easy shaping by hand into any desired geometry and the ability to work in confined spaces without noise or mess .

Besides , it doesn't require any experience from the user .

In addition , these sealants withstand temperatures from minus 40 to 93 °C and can be used on site in outside temperatures as low as zero °C .

The manual is only one page long and consists of four steps .

It's also quite comfortable to work with on your own .

In case roof work requires something heavier .

This hybrid of ladder and hoist will come in handy .

Two models are available with a capacity of 100 and 13 and 100 and 81 kilogrammes , both with electric motor or life fan or a Honda gasoline engine .

Lifting sections of 1.2 or 2.4 metres are also available , as well as stands for transporting solar panels or plywood and other accessories .

Competitors also offer their own variations , which can be set up in just 10 minutes , feature wheels for easy transport and can be powered from a standard American 110 volt household outlet .

Both options hold relevance now and in the future .

Germany is witnessing a resurgence in solar panel production , while France has introduced a law mandating their use in parking lots with 80 or more spaces .

Do you miss form work ?

It's time to fix that .

This Italian option combines sustainability and simplicity .

The basic material is recycled polypropylene .

The height and diameter of the tubes can be adjusted according to the customer's wishes .

This makes the formwork suitable for projects of all sizes , from private residences to schools and exhibitions .

For example , this formwork was used during the construction of a 25,000 square metre campus , reducing the duration of certain works by up to 80% .

In the video , you can see the expansion work on a 3000 square metre cold store where the usual temperatures are minus 25 °C .

The form work made it possible to create the ventilated cavity needed to combat excess humidity , preventing warping and cracking of the floor

Are you looking for a way to reach a wider audience and get more views on your videos?

Our innovative video to text transcribing service can help you do just that.

We provide accurate transcriptions of your videos along with visual content that will help you attract new viewers and keep them engaged. Plus, our data analytics and ad campaign tools can help you monetize your content and maximize your revenue.

Let's partner up and take your video content to the next level!

Contact us today to learn more.