https://www.youtube.com/watch?v=xuEusb_Ehks

DIY Modern Raised Planter Box _ How To Build - Woodworking

What's going on everybody ?

I'm Johnny Brook .

Welcome back to another craft workshop video in today's video .

I'm gonna show you how to build this kind of modern steel and cedar planter box .

Super simple diy project .

You could build it easily with a micro saw and a drill and I just love the way it came out .

It really kind of matches the other pieces that I've built for this back patio .

You guys might have seen that video a couple of weeks back , but this cedar and steel will just age really nicely and look gorgeous .

Love all the plants we got in here .

So hopefully you guys enjoy this one .

Let's go ahead and get started with the project .

The first step in this project was to break down the cedar boards into their final lengths .

And this build is made of cedar one by fours , one by twos and pressure treated pine , two by sixes , cutting the boards length could be done with a circular saw , but I use my minor saw with a stop block and it made things super fast .

I do also have detailed plans available for this project on my website which include a materials list , cut list and sketch up file .

And I'll have a link in the video description below .

In case you're interested after breaking down the cedar boards , I could start assembling the panels which make up the sides of the planner boxes .

First , I marked up an inch and a half from the bottom edge of the bottom board which will just indicate where I need to leave the gap for the two by sixes , which will make up the bottom , which will be added later .

Next , I squared up all the boards and laid out the one by two pieces .

And one of the pieces is just used to figure out the spacing as these panels kind of lock together by having this offset in the corners with the one by two spacer in place .

I added glue where the other one by two would be attached , use some eight inch spacers to set the distance between the boards and then attach the one by two to the one by four behind it with some one inch brad nails .

And also made sure to face all the rough faces towards the inside of the panels because I don't want those on the show face of these planter boxes .

As you can see , I'm using a T square to make sure things are nice and square during this process .

And this is really important .

I just kept working my way up the panel and using the eighth inch spacers between each board and then repeated the process on the other end of the panel .

After getting each panel built , I went back and reinforced them with some inch and a quarter screws .

And this really made the panels a lot sturdier and should help them hold up much better in the elements .

I was making two of these planter boxes .

So next , I repeated the process three more times to get my other short side panels .

And then I could move on to making the long side panels .

And these panels are built in the exact same way , first attaching the one by twos with glue and brad nails and then reinforcing them with screws .

And the only difference with these longer panels is there's an extra upright support in the center of the panel just to keep the boards from flexing under the weight of all that soil and water and plants .

One thing I should also mention is that the one by two pieces should roughly line up with the top of these boards .

And if it does , that will just kind of ensure that your panels are all the same size .

Once all the panels were put together , I could start assembling them into the planter boxes .

And you can see here how the one by twos contact each other in the corners , creating something along the lines of like a lock rabbit joint in each corner .

I also made sure to assemble the panels with the top edge of the planter box resting on my workbench just to make sure all those top edges all lined up nicely so that the trim would be even later on to make sure the connection between the corners was tight .

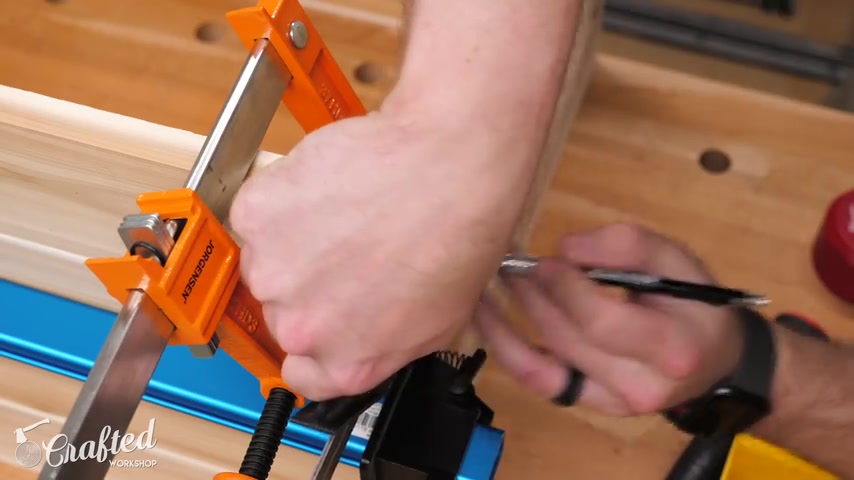

I clamped them together , making sure any gaps were removed .

Then I could add some two inch screws through the short side panels into the one by two on the long panel , I only added one screw at each corner at this point so the panels could still pivot so I could still snug up the other end of the panels .

Next , I flipped the planter box over planting the top ends of the panels together and then added more screws .

The screw should be about an inch and the eighth in from the corner of the planter box to make sure they connect with that one by two .

From the other panel with the outer walls of the planner box attached .

I could go ahead and get to work on the bottom .

The bottom is made up of two by six pieces .

And first I measured to confirm the lengths of the pieces I needed over at the Microsoft Station .

I could go ahead and get the boards cut to length , making sure to clean up that factory in on the first board , the bottom pieces are attached to the panels with pocket screws .

So I went ahead and drilled three pocket holes into each end of each board and getting the settings worked out here was a little bit tricky , but I eventually landed on having the jig set to the engine Three Ace setting and the depth stop collar on the bit set a , a little bit deeper than an inch and a half to install the bottom boards .

I just lined up the bottom edge of the two by six with the bottom edge of the panel clamped it in place and then drove in a few inch and a quarter pocket screws .

On this first board .

I used these pocket hole clamps but they actually left dents in the seater .

So I switched to parallel clamps for the rest of the boards with one board installed and my jig settings dialed in , I could drill pocket holes in the rest of the boards and this pressure treated lumber was so wet that it was clogging up the bit I got through it , but it just made a mess .

Once all the pocket holes were drilled , I could install the rest of the bottom boards .

As you can see , there's a roughly inch and a quarter gap between each of these boards just to allow for drainage .

And you don't need to go nuts trying to get this measurement precise here since it doesn't really matter .

I just worked my way in from the ends leaving a small gap between the boards and clamping the boards in place while I drove in the screws .

The last wooden pieces to add to the planter boxes were the trim around the top edges .

But first I sanded all the corner is nice and flush before doing that just to make sure the trim was seated .

Well , next , I measured my actual final length about 47 a half inches and then moved over to the miter saw to cut the angles .

And this is one area where using a circular saw would be really difficult as you don't have a lot of surface to rest the saw on .

So I definitely recommend using AM saw here .

If you have one to cut the trim , I first cut a 45 degree miter on one end , then flipped the board around marked my length and cut an opposing 45 degree miter on the other end .

And I always leave these pieces a little bit long at first and then trim them the final size based on the actual dimensions .

After getting one piece to the right length , I used it as a template for the second long piece of trim , which you can see me doing here with both of the long pieces cut to size .

I attached them to the planter box with glue and inch and a half brad nails .

The one by two uprights were a great spot to drive in the nails here .

And I also made sure the edges of the one by twos were nice and flush with the outside of the panels .

Once the long trim pieces were installed , I measured the length for the short trim pieces and cut them in the same way over the minor saw .

And this is kind of the fit you want with the edge of that one by two flush with the panel .

And also I know it looks like there's a gap in the minor here .

The pieces are actually slightly different thicknesses .

If you work with these kinds of cedar boards , you'll notice all kinds of inconsistencies like this .

But luckily it's nothing a little sanding can't fix .

Speaking , which with all of the wooden pieces installed , I could go ahead and give the outside of the planter box a good sanding with 80 degree sandpaper .

The key areas to focus on here are the corners which you want perfectly flush as well as the trim .

I also made sure to round over the corners as the angle iron I use for the legs has a rounded inside corner while I say and let's talk about the sponsor of this week's video Rie Mask .

I've been using the R mask M 2.5 for the past month or so and have been loving its comfort and functionality .

It's super easy to take on and off and I've been using the mask for different applications like sanding , metal grinding and more .

Another big plus with a mask is there are long lasting filters that are really easy to replace , to get 15% off your purchase .

Follow the link in the video description below and use the code craft workshop and thanks again to a mask for sponsoring this week's project .

After sanding , it was time to make this box ready for some planting .

So first I lined the bottom with some galvanized steel mesh to keep dirt from falling out of the gaps in the bottom .

If the plastic breaks and I picked up these tips from a planter box video that Ben over at homemade modern did so make sure to go check that video out as well as his design looked awesome .

As always with Ben's work , I used some aviation snips to cut the mesh to size , formed it to fit the bottom of the planter and then stapled it into place with half inch staples .

And I did cut a the areas where the mesh came into contact with the one by two uprights so that the mesh could lay flat .

I repeated this process on the other half of the planter off camera , making sure the mesh overlapped in the middle and then I could add some plastic to line the planter box .

I used two mil plastic drop cloth here which wasn't as thick as I wanted it to be .

So I doubled it up to make sure the plastic didn't break under the weight of all that soil .

And then I stapled it into place after installing the plastic I punched some holes through it with a screwdriver just for some drainage .

The last step in this build was the legs which I made from some steel two inch angle iron .

And since I use steel here , I cut down the pieces on my metal chop saw , but you could also use aluminum angle and cut it on a regular miter saw .

You could also get the angle iron from a steel yard and they would cut the pieces to size for you .

I set up a quick stop block to cut the pieces to length as it's super important that they all match perfectly .

After cutting the pieces in length , I rounded over all the sharp edges using my belt grinder , but an angle grinder and flap would also work great .

Here .

Next , I needed to drill the holes for the screws .

I used to attach the legs to the planter boxes and I wanted all of these holes to line up nicely .

So I marked them all out on the inside faces of the angle iron and one tip here , I love these paint pins for marking on steel .

They show up a lot better than most sharpies and the paint is removed really easily with a little acetone and with all the hole locations marked out , I drilled the holes over the drill press , making sure to use cutting fluid to keep my drill bit from getting too hot .

Once all the holes were drilled , I wiped all the pieces down with acetone to remove the paint pin cutting fluid and any other surface contaminants and then sprayed on a few coats of flat black enamel paint .

After letting the paint dry , I attached the legs to the corners of the planter boxes using construction adhesive and screws .

And I used the inch and a quarter screws for the upper two holes , but could use 2.5 inch screws on the lower holes since the hole ran into those two by six bottom pieces .

And one thing to look out for here is there could be some screws underneath some of these holes , depending on where you put the screws through the corners of the panels before .

And also , I probably should have pre drilled these holes as I did get a little bit of splitting and then I could get the planter boxes filled .

Luckily , my mom was in town when I built these planter boxes and she's a master gardener .

So we bought a bunch of plants and got them looking really nice .

And with the plants added , these planner boxes were done .

All right .

Hopefully you guys enjoyed this one .

I just love the way these came out .

They're extremely simple to build .

You don't need many tools at all really .

You could get away with just a micro saw and a drill .

Now , if you guys have never worked with any kind of steel before , don't let that stop .

You you could definitely have a local steel yard cut all of these pieces of links for you .

So that way you don't have to deal with any cutting of steel and then you can drill holes in them with your handheld drill , just like any a piece of wood .

You just need to use a different type of drill bit .

And it's really , really simple .

So I did end up using the blue 2.5 inch long pocket oil screws , which I think added a really kind of cool contrast against the black legs and obviously the plants I think looked great .

My mom , as I mentioned earlier is a master gardener .

So these just came together super , super nicely .

So hopefully you guys enjoyed this one .

Again , I do have plans available .

I have links to those in the video description below along with all the materials and tools I use on this project .

Also , I want to say a big shout out to the sponsors of this week's video R mask and then festival who you might have noticed , I used a lot of their tools in this project .

They're one of my newest sponsors on this channel and I'm really excited to have them on board .

Obviously , I love working with their tools .

You guys have seen them in previous videos , so you'll just see more festival stuff coming up .

So again , thanks for watching everybody .

If you don't already go ahead and get subscribed .

And ring that little notification bell .

So you don't miss any of my future videos .

And until next time , Happy Building .

Are you looking for a way to reach a wider audience and get more views on your videos?

Our innovative video to text transcribing service can help you do just that.

We provide accurate transcriptions of your videos along with visual content that will help you attract new viewers and keep them engaged. Plus, our data analytics and ad campaign tools can help you monetize your content and maximize your revenue.

Let's partner up and take your video content to the next level!

Contact us today to learn more.