https://www.youtube.com/watch?v=uk_nC9anQcM

How to Align a Hydraulic Disc Brake on a Bike

A rubbing disc brake is a common problem and even the slightest rub which might not really be slowing you down can still be annoying .

This is hydraulic disc brake alignment and regardless of brand or model this video will help you get rid of that .

Pesky rub .

Hey , I'm Truman of the Park tool .

Hydraulic brake alignment is relatively simple procedure , but there are other things that can cause the pads to rub .

So we're gonna start with diagnosing the problem and then we'll take you step by step through the alignment process .

If you have mechanical brakes which are actuated by a cable , see this other video for alignment , typical tools and supplies include four or five millimeter hex wrenches or a T 25 .

Also a torque wrench such as a T W 5.2 , a light source to back light the caliper and a repair stand or some way to hold the bike up while spinning the wheel first , we'll elevate the bike , spin the wheel and cite the gaps between the rotor and pads back light the caliper to make it easier to see .

This is a good time to give the pads a quick visual inspection for wear .

These pads have lots of life left , but these other pads need to be replaced .

See this other video to learn how to measure the wear and replace the pads if needed .

Back on our spinning wheel , we see there is no rub between the rotor and pads .

So in this case , we would consider ourselves done with the alignment .

And in this example , there's a slight rotor rub and there's barely any noise .

So you might just call this one good to go .

But even with clear rotor R , we should at least be aware of other things that can cause or amplify .

This symptom wheel alignment is critical to check , especially on open dropout bikes , fully seating the wheel can solve the problem and it can even work on through axle bikes .

A bent rotor will show a lot of movement side to side and this makes pad alignment difficult or impossible .

Rotor replacement is a good option but some rotor towing may be possible .

And that process is shown in this other video , you should also check the rotor for play .

Rotors are secured using either mounting bolts or a lock ring .

See this other video for rotor installation bearing play at the hub can also be easy to check for just rock the wheel back and forth as shown if there's play , fix it .

Another issue is when dust and dirt collects on one or both of the pistons and causes them to stick .

In many cases , you can still achieve proper alignment with sticky pistons .

But for more information , see this other video .

That's finally it for diagnosis .

Let's get into the alignment procedure .

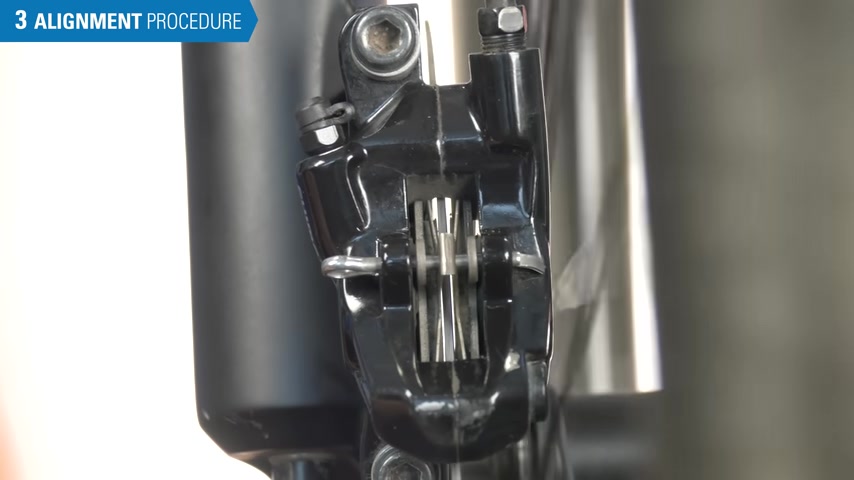

Alignment procedures are the same for front and rear brakes loosen the mounting bolts until the caliper body is able to freely move side to side .

Note that on some bikes , the mounting bolts are under the stay or on a bracket .

Now we squeeze the brake laver .

This centers the caliper body over the rotor while holding the lever , snug up the bolts , release the brake lever , spin the wheel to test for pad rub .

If there is no rubbing , the pads are aligned secure the mounting bolts to full torque , 6 to 8 Newton meters and your work is complete .

If the pads are still rubbing , we need to do some fine tuning loosen one bolt at a time and adjust until there is a gap on either side of the rotor .

Take extra caution with your fingers and tools while working near a spinning wheel .

Once the pads are not rubbing fully secure , each mounting bolt , typically 6 to 8 Newton meters and the process is complete .

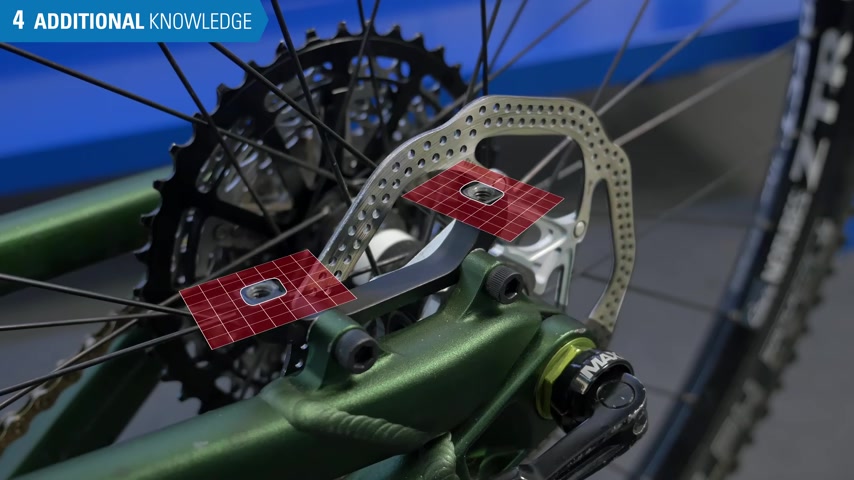

Some brackets have conical washes to assist in perpendicular alignment , do not add washers if none were designed to be there in the first place as the pads will no longer align with the rotor conical washers can also be found between the bolt head and the caliber these washers allow for proper bolt head alignment .

If after trying all these procedures and nothing seems to work for an adequate alignment .

There may be issues with your caliber mounting system .

It is assumed the frame mounts are correctly machined and square with the rotor .

But if mounts are not square bike shops are able to face or machine the mounts with the park tool D T 5.2 to improve alignment .

As seen in this other video .

Thanks for joining us on hydraulic disc brake alignment .

If this video helped you out , please share with your friends and subscribe to our channel .

Sometimes all it takes is that one bit of knowledge to take your ride , your friend's ride or your customers ride to the next level .

Thanks for watching .

Are you looking for a way to reach a wider audience and get more views on your videos?

Our innovative video to text transcribing service can help you do just that.

We provide accurate transcriptions of your videos along with visual content that will help you attract new viewers and keep them engaged. Plus, our data analytics and ad campaign tools can help you monetize your content and maximize your revenue.

Let's partner up and take your video content to the next level!

Contact us today to learn more.