https://www.youtube.com/watch?v=yNWeTDpy740

DIY Epoxy Table - Step By Step Guide - Part 2

Hey , what's up everyone ?

My name is Greg and welcome to my channel .

This is going to be part two of our Epoxy table built .

And if you didn't check out part one , I am going to leave a link down in the description and there will most probably pop up a link now where you can go and check out part one first before you continue watching part two .

So in part one , we covered most of our preparation in our epoxy table belt and moving on to part two , we are almost done building our molt .

And as you can see , I'm just busy applying some silicon in the edges of my molt .

The reason why I'm doing this is once I'm going to pour my epoxy into my molt that it's not going to be able to leak out .

Now , moving on to the next step , we are going to apply some mold , release wax to the inside of our molt .

And this is just the purpose for once our epoxy table is finished , it's going to come off easily .

Now , I know there's a lot of people that's using the tape , but I prefer the wax method .

And when you're applying your wax , you have to make 100% sure that you cover all the corners inside your molt .

Now , in part one , I did cover the topic that your work surface needs to be 100% level .

And this is also going to be the next step in your epoxy table built is to make sure that your molt is also 100% level .

You don't want to pour your epoxy into a table that's not sitting level .

This is going to force the epoxy to go to the one side that's not level .

You have to leave the molt , release wax inside your mold for about 20 minutes before you can start packing your wood into your mold .

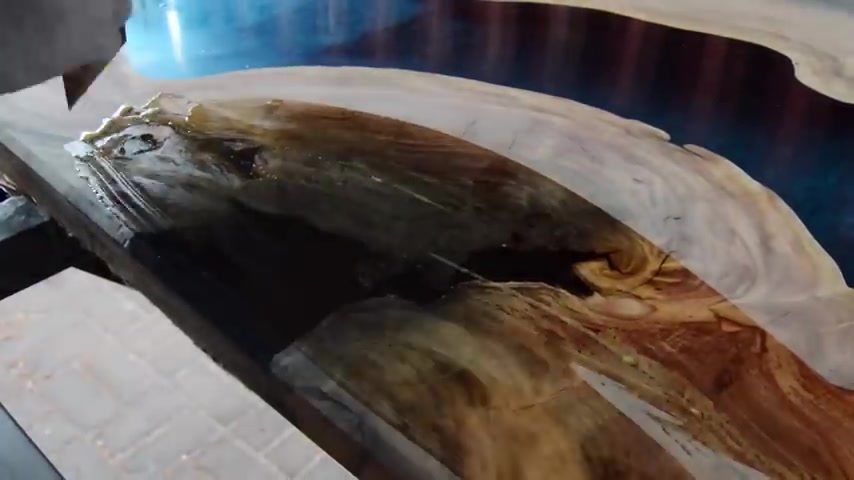

So now we're moving on to the next step and that's by placing a slab inside your mold .

And as you can see , I'm applying some cross braces onto my slap .

I'm going to be fastening it with some clamps to make sure that my wood is not going to move at all .

Once I'm going to start pouring my epoxy .

Now , I'm just doing some large double checking to make sure my molt on the inside is 100% clean just using an air gun to spray the large dust particles out .

The next step in our epoxy table build is to work out the amount of epoxy we're going to need for our table to work out the amount of poxy .

We're going to need , we're going to need to work out the volume of the open spaces inside my epoxy table .

So I personally only know two methods of how to work out volume .

The first method is the method I'm using and that is length times , width , times height .

And the second method is you can just use bags of rice to fill all the open spaces in your epoxy table .

Then you can remove all the rice , add it in 20 liter buckets and then you'll get a good idea of how much epoxy you're going to need .

Once you have the volume amount of your epoxy table , you can use an online calculator to convert your volume to liters or two kg .

So me and my client decided to go with a light see-through aqua color .

When you mix your color agent into your poxy , make sure you mix a little at a time to get the perfect color you want .

So while you're busy checking me out humping the epoxy .

If it's your first time here and you want to learn more how to diy guys , please subscribe to my channel .

And if you like this video , please give it a thumbs up .

It's gonna cost you nothing and it's definitely going to help the channel grow and help me to make future content .

The epoxy I'm using is a 126 ratio .

Please do not use this ratio for wherever you are in the world .

All the epoxies has got different ratios for mixing it together .

And the specific epoxy I'm using is not being calculated by liters .

It's calculated by weight .

That means for every one kg of resin , I have to add 600 g of hot milk .

When you are done measuring your epoxy resin and hot , you need to mix them together for at least three minutes .

Once you are done mixing everything together , you can leave it for about 10 minutes and all the air bubbles will come up and then you can just use your gas gun to remove most of the bubbles before you do your first pour .

Finally , we're getting to the fun part of this video and that's by pouring our epoxy into our mold .

This specific epoxy I'm using , I can only put 10 millimeters to 15 millimeters at a time .

So that means for my total table , I'm going to do four pores .

And as you're going to pour your epoxy into your molt , you're going to see a lot of bubbles .

You can just use a normal flame gas gun to remove all your bubbles in your epoxy table .

Eight hours later , I'm back to do the second pour in my epoxy table .

So there's one specific topic in the epoxy table world that everyone is arguing about and that is to seal your life edges with epoxy or not .

So for my specific project , I decided not to seal my edges just for the plain reason that I'm thinking the epoxy is penetrating the wood better and it's giving me a better bond .

But in the same breath , if I could go back and do it differently , and if I can give you some advice and one of the small mistakes I made is that there were small specific spaces on my table that the wood was releasing some air bubbles and to fix this small problem , I would definitely have a small brush in hand .

When the POY is about 50% dry , I will definitely come and brush the inside of my poxy onto my life edge just to release the last little bit of bubbles .

Now , we're going to remove the table from our molt and I honestly do have to say that the wax definitely done its purpose .

Now , for the next step , I put my table back onto the router slip and I took off about two mils at the top and at the bottom .

Now , in part one , I did mention to build your milk 10 millimeters bigger on all the sides .

And this is just for the plain reason .

Once your table is done , you can cut it down to its final size and have a nice neat clean finish right around .

Now , we're going to move on to the sanding process for this epoxy table built .

And honestly speaking , this was one of the most time consuming processes of this whole project .

Starting your sanding process with 100 grit sandpaper on your belt sander .

This is just to remove all the bigger markings , the router slide mate and after you finish with your belt sander at the bottom and the top of your table , we're going to move to the orbital sander .

We're going to start off with 100 and 20 grid sandpaper .

Then we're going to move on to 100 and 80 grid .

220 grid , 300 grid , 400 grid , 500 quid , 600 quid , 800 grid , 1000 grid , 1000 200 grid and then 1000 500 quid .

And yes , as I told you , it's an extremely time consuming process .

This process took me about 2 to 3 days to get this high end finish .

Moving on to the next step .

I don't want the top of my table to have a very sharp edge .

That's why I'm just going to give you a small champ right around with my router moving on to the polishing part of this table and this is where the magic is going to start to happen .

We're going to start off by polishing our table with a 2000 grid sponge sandpaper .

And then we're going to move on to a 3000 grit sponge sandpaper .

And the last step to polish your epoxy .

I just use the normal sponge polisher to give it a nice smooth finish .

Now , the absolute last step in your epoxy table bill is just to apply some oil to your wooden sections of your table .

The specific product I'm using is Rubio Monaco to , it is a linseed oil .

And I've been using this product for about a few months now and I honestly do have to say I'm super satisfied with the finish it's giving me and I would definitely recommend getting this product for all your wooden projects .

So once you apply rubio mono code to your wood , you have to leave it for about 10 minutes before you wipe it off .

Now , remember the wood is only going to take the amount of le seed oil it needs and then the excess you just wipe off .

So this is going to be the end of our two part series Epoxy Table Built .

And before I'm going to leave you with the final product , I honestly hope that this step by step video is going to help you to build your own .

And if you have any questions , guys , you can ask me in the comment section below and remember to subscribe and if you like this video , hit the thumbs up .

Cheers guys .

Are you looking for a way to reach a wider audience and get more views on your videos?

Our innovative video to text transcribing service can help you do just that.

We provide accurate transcriptions of your videos along with visual content that will help you attract new viewers and keep them engaged. Plus, our data analytics and ad campaign tools can help you monetize your content and maximize your revenue.

Let's partner up and take your video content to the next level!

Contact us today to learn more.