https://www.youtube.com/watch?v=89WeF52XwcI

Build Cabinets The Easy Way _ How to Build Cabinets

Oh , hi .

Welcome to the first video of a three part video series I am doing on how to build a cabinet .

In this video .

Part one , I'm going to show you how to build a cabinet , carcass including the carcass , box construction as well as the face framing .

And the next video , I'm going to show you drawer construction and drawer slide installation .

And then in the final video , I'm gonna show you how to do drawer faces and cabinet door faces and install .

So watch this video , learn how to build a carcass and stay tuned for the other two videos .

Enjoy what ?

Ah , so , so high .

Yeah .

You know .

All right , let's jump right in here .

Now , cabinets are nice because you don't need a lot of materials for this cabinet .

We're simply using one sheet of three quarter inch plywood , a few sticks of three quarter inch poplar for face frames and one sheet of quarter inch plywood for our back panel .

In my opinion , the easiest way to go about building cabinets is to first precut all of your pieces .

Then with all of your pieces precut , all you have to do is well , hook them together .

Now , as we go through this video , there might be some steps that may be a little confusing .

You might say , what the heck is he doing that for ?

I don't understand , but I promise if you just watch the full video , it will all come together and make perfect sense in the end .

So we're gonna start by first cutting out the three main pieces of our cabinet box .

This includes both side pieces as well as our bottom piece all cut from three quarter inch birch ply .

Next on the bottom of both of our side pieces , we are going to cut a three quarter inch data groove .

This will allow us to attach our side pieces to our bottom piece without having to use any exterior nails or screws that will be visible from the outside of your cabinet .

So after setting your blade to half inch to leave a quarter inch material on the plywood , I like to put a sacrificial fence in place .

A sacrificial fence is simply a piece of wood that allows us to push the fence all the way up against the blade without scarring up our permanent fence .

Hence the word sacrificial .

Now I'm doing this because as you see , I'm not using a data stack , why you ask ?

Well , it's because I'm lazy and I also wanted to show you that you can do this without a data stack .

If you don't have one , you just have to make multiple passes to remove the desired three quarter inches of material .

But in order to get the most accurate cut , it's best to start in at our desired depth and then work our way out towards the end of the board until the blade is flush against that sacrificial fence to make our last cut .

As you can see , I've dated out a nice three quarter inch groove at the bottom of both of my side pieces .

This will allow me to hook those side pieces into the bottom piece just like this .

Then with both of our side pieces , data , I'm going to remove the sacrificial fence and set my fence to four inches .

Then I'm just gonna run some scrap pieces of plywood through and get a couple of strips of four inch wide material .

You'll see why in just a second .

Then I'm gonna set my blade to a quarter inch high .

Next , we have to data out a quarter inch groove on the back of our two side pieces as well as the back of our bottom piece .

This groove will catch the back panel of our cabinet box .

Like I said , this all makes sense here in just a few minutes .

Again , I am not using a data stack .

So you'll need to run the board through twice to get your desired quarter inch thick data .

And it's also very important to note that that data needs to sit in three quarters of an inch from the back of your panels .

You'll see why in just a second .

Just hold on .

Be patient .

Jeez .

I like to keep a piece of scrap , quarter inch ply handy just to make sure that it'll fit nicely in my data out groove .

When you're done cutting all the datas on your side and bottom piece , turn your saw off and just leave it alone .

Don't change the settings .

We're gonna need that data setting here in just a minute .

But in the meantime , we can hook together the first three pieces of our cabinet box .

As you can see that data out grove perfectly lines up from each side piece to the bottom .

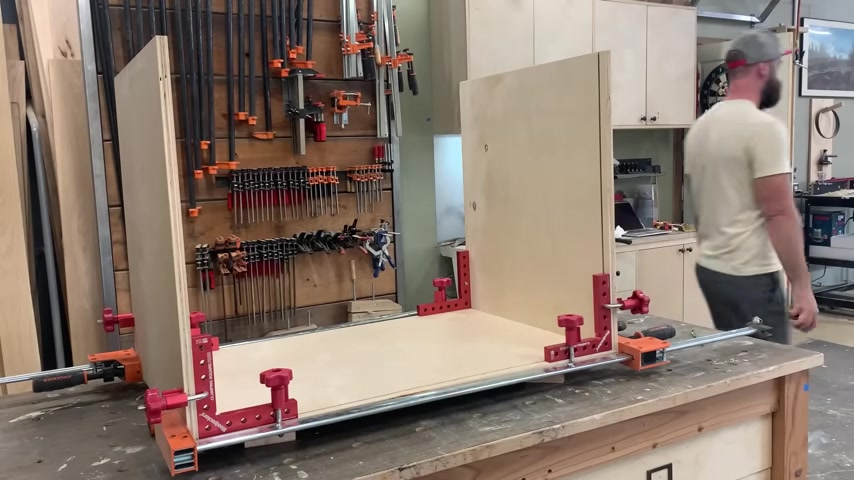

And this will create the perfect channel for us to slide in the back panel of our cabinet to make gluing up our cabinet box easier .

I like to raise my bottom panel up off my work surface .

This just allows me to get clamps underneath it and you know , not fiddle around on a flat surface .

Here's some helpful advice .

If you're gonna do cabinet boxes with any regularity , go out and invest in some of these woodpecker clay thingy ma jigs .

They make clamping up cabinet boxes by yourself incredibly easy as well as allowing you to ensure that everything is nice and square as you can see , your side panels should perfectly fit into your bottom panel with that three quarter inch data we cut previously .

Then all you need to do is simply apply a liberal amount of glue onto the inside of that cut data and use a glue brush .

As you can see , I'm using my patented bourbon moth glue brush to smear the glue around and then just hook it in place as well as the woodpeckers clay thing .

He's worked for alignment .

I don't really trust him for sheer clamping force .

So when everything is aligned exactly how I want it , I like to throw on a few additional clamps as it glues up .

And just like that , we have the first three pieces of our cabinet box hooked together .

Now we just have to wait for the glue to dry and then we can start working on the upper pieces .

But in the meantime , we can get all of our additional pieces cut to size and ready to rock once that glue is dry .

Remember those random four inch strips I had you cut down earlier .

Yeah .

Now is where you're gonna use them .

So you're gonna want to cut down four pieces of four inch scrap plywood .

Now , they need to be the exact length of the inside of your cabinet box and then one of those four pieces is gonna need another quarter inch data groove .

Good thing you left your saw alone because now you just run it through then using a Craig jig , we are going to drill pocket holes into the end of each one of these four pieces .

This will allow us to hook these brace pieces inside the cabinet and not use any screws coming in from the outside that you'll have to , you know , look at or fill or something like that .

Then with all of our brace pieces cut , we just have to cut the back panel of our cabinet box .

Now , the cabinet I'm building is actually gonna be completely full of drawers .

And so essentially you wouldn't really need a back panel .

But I wanted to show you how to do this .

Because if you're building a cabinet with cabinet doors , you're gonna want that panel in there .

So you don't just see a ugly wall behind the cabinet .

Then the final thing we need to do before actually constructing our cabinet box completely is to build a kick plate for the box to sit on .

Now , some people integrate the kick plate into the actual cabinet box itself .

I'm not a huge fan of this .

I like to do a separate kick plate that way I can install my kick plate , get them shimmed and level .

And then all I have to do is drop my cabinet box on top .

Easy peasy lemon squeezy .

Now most kick plates are between 3.5 to 4 inches .

I like to go 3.5 .

No need to go up to four .

That's just crazy .

So I cut down all my pieces for my kick plate and then I drill them out again .

With pocket holes and we use those to assemble it .

So you won't see any of those pesky screws .

All kick plates are a little different depending on the orientation of your cabinet .

This is how ours is gonna look , you'll notice that one of the corners is MD .

That's because you'll actually see the kick plate on both sides .

So we want to m that corner .

So we don't have any exposed plywood either on the front or the side of the cabinet .

This is how I like to do M corners on my kick plates .

They might not be the right way or the only way .

But this is my way .

I first take a piece of blue painter's tape and I tape both pieces together with each end of my M perfectly touching .

Then I apply a dab of wood glue into the center of that miner leaving a little room on each edge .

Then I use a few dabs of C A glue on either side .

And the accelerator spray , the C A glue is gonna dry instantly and hold the miter together .

While my wood glue dries , essentially , the C A glue is acting like a clamp .

In this case , it's way easier than trying to get some clamps on and funky angles and hold pressure on that Mitter till the wood glue dries .

It also speeds up productivity because I can take the tape off immediately and continue constructing my kick plate .

Finally , I just hit the corner with a little 2 20 sandpaper , you know , to make it look pretty .

And then I construct the rest of my kick plate again , using those pre drilled pocket holes that we did .

You know , a little while ago in this video , then with our kick plate done , call me old fashioned , but I like to start working off the floor .

I mean , that's where my cabinet is gonna sit in the end .

So might as well get down there as soon as possible .

So I set our three sided cabinet box on top of the kick plate and then I can start assembling all of my internal brace pieces as well as my back panel .

Now , you might have guessed this was coming .

But our one brace piece that we cut the quarter inch groove sits on top of our back panel and locks it in place .

Then I like to use just one clamp to hold my brace in place while I secure it with four pocket screws .

Then I repeat the exact same step this time on the front of the cabinet with the front brace piece .

And you guessed it , I do it two more times both on the bottom and top of the back of our cabinet .

These are what is known as our lower and upper nailer pieces .

These are the pieces that will actually screw through to secure the cabinet to the wall .

And as you can see , because we inset our back panel , three quarters of an inch from the back of our cabinet .

Those pieces sit in there very nicely .

Now , the cool thing about cabinet construction is you can use it in a lot of different ways .

This top nailer piece could be cut with a 45 angle on the bottom to become a French cleat .

That way you could actually hang the cabinet off the wall if you were doing , you know , like an upper cabinet or something .

Then finally , I like to take a few inch and a half cabinet head screws and just secure my top brace into my back brace .

This just shows everything up and make sure it is not going anywhere .

You could probably get away without doing this .

But when it comes to actually securing the cabinet to the wall , this will keep that back piece from bowing out at all .

And then I flip it over and do the exact same thing to the bottom as well .

And with that , our box is constructed and now it's time to face frame to construct our face frame .

I'll be using three quarter inch popular .

This is a paint grade piece and popular paints amazingly .

Now , if it was going to go in a kitchen or bathroom someplace high traffic , I might do something a little harder , like hard maple , but this is for an office so popular .

It is when constructing my face frame , I like to start by just laying out the entire thing on the cabinet box itself .

That way I know it's going to be perfect .

I always like to do full runs on the side of my cabinet .

So there's not any visible end grain .

So after cutting them down to size next , I like to clamp them in place to get them exactly where I want them .

Usually leaving about a 32nd of an inch overhang on my plywood so that I can sand it back smooth with my two side pieces in place .

I then fit my internal pieces , making sure they fit very nice and snug not so tight that they push my outer pieces out but also not too loose .

So they , they bring my outer pieces in , see how that works .

I think it's physics or something .

Then I mark all of my pieces just so I can keep track of exactly where they go .

Then I take them off the cabinet box and move over to the bench top and hooking them together from the backside .

I use again pocket holes .

I used to hook all my face frames together with dolls or dominos , but it's just a pain in the butt to try and get everything assembled , especially with internal face structures .

And for cabinet grade pocket holes are actually designed for this very purpose .

So don't feel bad using it .

I assemble each joint with just a dab of glue and then I like to clamp it directly down to my tabletop using one of these little grizzly hold down , clamps .

This just makes sure it doesn't slide up or down as I screw it together .

And after I do one corner , I just work my way around until I have done all four corners and completed my frame .

Then with the exterior of my face frame done , I can start working on the interior components .

Now , this particular cabinet is going in an office .

It's going to have four drawers in total , two larger drawers on the bottom with two smaller drawers on top .

So I start by first putting in my center piece .

Once I have that hooked in place , I can cut my smaller pieces .

That will be my drawer dividers .

Again .

You want to make sure these are nice and snug .

I tried to do a sexy dust blowing thing , but I got sawdust in my eye .

What an idiot then to position your drawer dividers properly .

The best way I've found is to cut some spacer blocks .

You can just set them on the bottom of your face frame and then you just set your drawer divides in place .

And this will ensure that all of your drawers are identical and nice and square .

Then you just put them in place with those handy dandy pocket holes and just like that , your face frame is complete .

See , look , I've been framed , I've been framed anyways with our face frame , complete it is time to attach it to our cabinet box .

Now , there's more than one way to skin a cat and there's more than one way to attach a face frame and it kind of depends on what kind of cabinet you're building .

If you were doing a wood grade stained cabinet , then you could use pocket holes on the outside of the cabinet if it's butting up against another cabinet , so you won't see the side or you could tack it on from the top that might work and you could fill the holes .

If it's gonna be all drawers like this one , you could use pocket holes from the inside because you won't actually see the inside of the cabinet .

But since this is paint grade , I decided I was just gonna bam , bam , bam , nail it on and fill all my holes because that's the easiest way to do it .

And for paint grade , you can get away with it .

So the first thing I do is lay down a nice thick bead of glue around the entire perimeter of my cabinet box .

And then using my patented glue spreader , I spread it out and just plop the face frame on there .

And then once it's right where I want it , I just tack it down with about , you know , 4 to 5 nails per side until it is held securely in place .

When it comes to filling nail holes , there are good ways to do it and bad ways to do it .

This is what I like to use .

It's this dap plastic wood .

They make two kinds of this product .

A water based as well as an alcohol based .

Definitely spring for the alcohol based .

It works much better and dries much quicker .

Now , when you fill the hole , you don't want to just push it all down there so that the wood filler is flush with the top of the face frame .

You want to fill the hole and then kind of mound the filler up on top that way as it dries and shrinks , which it will do , it will shrink into that pile .

So that when you sand it , it will be flush and you won't have shrunken little nail holes all the way around your face frame .

Next is the bane of every cabinet maker's existence is trying to get no line where your face frame meets your plywood .

Now , the best method I have found for achieving this is this product by Mohawk .

It's a two part epoxy filler .

The white part on the inside in the black part on the outside .

It also comes in multiple colors .

I prefer the black .

So I can see when I've sanded it away .

You just mash it together and smear it in the crack .

It dries crazy hard and it doesn't shrink , which is really nice and it'll give you a perfect seam .

Then with that all filled , you just have to sand your face frame thoroughly , getting rid of any ridges or edges .

Now , stop everything for a second .

I've heard a lot of people say when they're sanding the transition between face frame and plywood that they're very worried about burning through the plywood veneer .

Now , I understand this .

If you're doing a finish grade piece with a veneered hardwood plywood , but when it comes to paint grade , don't worry about sanding through the veneer .

You want a smooth transition .

That should be your number one goal .

And if you have to sand through the veneer , like you're gonna see me do here in just a second to achieve that it's worth doing .

It'll paint beautifully and you'll never be able to tell that you went through the veneer once it's all painted as you can see , I couldn't give two cares that I'm burning through the veneer .

All I care about is that you're not gonna be able to see the seam between the face frame and the plywood .

And then the very last thing I like to do is just take a piece of sandpaper and by hand break down all the internal edges of my face frames .

There's no splinters or chip outs and they are nice to the touch .

Well , hoo hoo to Lolly , our cabinet is done and ready for drawers and eventually draw faces .

Hey , well , I hope you enjoyed that video .

I hope you learned something as you can see building a cabinet carcass isn't really that difficult .

You can definitely do it by following all the steps .

I just showed you and stay tuned for the other two videos that will be coming out in the coming weeks where I show you how to do drawer construction , drawer slide installation as well as drawer faces and cabinet doors .

So you're not gonna miss that .

Also check out some of these other videos that are floating around my head and click that subscribe button right down there .

Ok , bye .

Are you looking for a way to reach a wider audience and get more views on your videos?

Our innovative video to text transcribing service can help you do just that.

We provide accurate transcriptions of your videos along with visual content that will help you attract new viewers and keep them engaged. Plus, our data analytics and ad campaign tools can help you monetize your content and maximize your revenue.

Let's partner up and take your video content to the next level!

Contact us today to learn more.