https://www.youtube.com/watch?v=JtqwYrJNCbI

How to Tile a Small Bathroom Floor _ DIY Bath Remodel

What's up guys ?

I'm Brad Rodriguez from fix this build that .

And today I'm gonna show you how I replace the dated floor tiles in this small bathroom with these great large format tiles that really open up the space .

Stay tuned and I'll show you just how I did it .

This small bathroom has been on our remodel list for a while and one of the things I hate most about it is the beige tile floor in the dark crowd .

Now we're remodeling the entire bathroom .

So we ripped everything out from the tub to the mirror .

Today , I'll be focusing on the floor install using the new line of tile tools from rigid .

After taking everything else out of the bathroom , I moved on to the floor .

I used a large demo bar to pry up the tiles and it worked really well .

And my subfloor is three quarter inch Os B with the detra underlayment .

I'll talk more about that later , but ripping up the tiles actually shouldn't be this easy .

They didn't install it correctly , which made my life easier , but don't expect yours to necessarily go as smoothly .

You may need a hammer drill with a scraping blade to get up all the Mastic off the subfloor after I installed the tub in the shower , which you'll see in the next video , I started prepping the sub floor for install .

Having a flat surface to start is key in any flooring .

Install .

My OS B subfloor was mostly flat but the seams were raised up a bit .

So I grabbed my belt sander and I flattened all the seams .

even with the rest of the floor , I'm using Schluter die for the underlayment .

That's the same stuff that was on there before .

It's an alternative to backer board .

And it's both an uncoupling membrane and a waterproof .

I measured the floor to cut the roll to length and it's easily cut with scissors or a box cutter .

I notched it for the doorways leaving a quarter inch gap from the walls .

The second piece to fill out the room is not full width .

So I cut it down to size and I laid it on the floor to reference the toilet flan .

I used my box cutter to cut out the hole for the flange .

So it just slipped over the opening for an OS B Subfloor installation .

It calls for modified mortar between the wood and the underside of the detra .

I mixed up a batch of the mortar using the new rigid mixer here and this thing makes short work of mixing and it's got the power to do it versus a common drill , which you can easily burn up if you're mixing too much mortar and pushing it too hard .

I got the mix to a thick milkshake consistency .

Then I let it sit to slack and mixed it up again after 10 minutes .

And I probably could have gone a little wetter with the mix because it did stiffen up some after sitting .

And when you're done mixing the mortar , the quickest way to clean your paddle mixer is to put it in a bucket of clean water and run it at high speed , cleans it in a jiffy .

Now , for my application , the mortar gets applied with a quarter inch by 3/16 inch V notch trial .

And this could vary depending upon your underlayment and die type .

So make sure that you reference the detra install handbook .

I spread the mortar onto the subfloor and then I laid out the larger piece .

It's a little tricky handling the full length sheet from the side .

I think on rolling it from the doorway , it would have worked a little bit better here and using a grout float .

I pressed the detra into the mortar bed and smoothed it out around the whole sheet .

I also peeled up a corner to check for adhesion and made sure it was bonding to the subfloor .

It wasn't exactly perfect but it was definitely way better than the original install .

Next .

I spread the mortar over the rest of the subfloor and pulled in the smaller sheet of the fit was perfect up against the other sheet .

And for full waterproofing , a layer of Schluter curdy band could also be added to this joint .

You can actually start laying tile on top of the deer right away , but it was late .

So I came back the next day to start the tiling and I'm using a 24 by 12 inch large format tile and I spent some time trying to figure out the best layout .

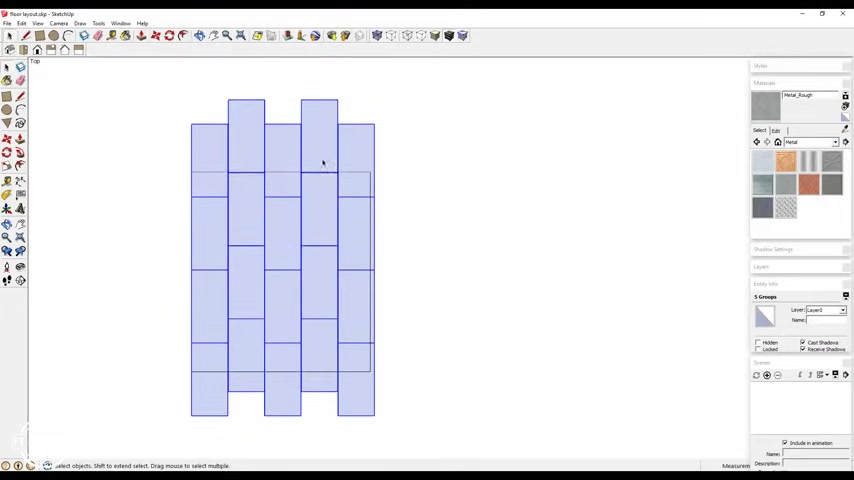

I used a program called sketch up to lay out the size of my floor and my tiles with the ground spacing that I wanted .

This .

Let me try different staggering and placements to see how they looked right there on the computer screen .

And my goal is to have as many full tiles as possible and make sure that they didn't have any small near the walls or the doors .

We settled on a brick pattern layout with a third of a tile overlap between the tiles .

And this helps to reduce lipid when two tiles aren't level with each other , which is more prone on these larger tiles because they aren't always flat .

And when using a printed pattern on the tiles , it helps to lay out all the tiles that you have across different boxes .

So you can avoid duplicates next to each other .

If you do have a duplicate that you'll have to use , just make it a cut piece , flip it in for in versus the other one or hide it underneath the vanity or the toilet .

After we got the layout , we wanted , we labeled all the tiles and then transferred that to a print out of the computer layout .

We designed that way in the midst of laying the tiles , we could use it as a reference and not get mixed up and put those duplicates back together if you're new here and you like what you're seeing so far .

Go ahead and subscribe and say hello down in the comments .

The door jams needed to be cut back a little for my thicker tile and mortar bed .

I used to tile on a small spacer to represent the mortar and I cut the jams with my job .

Max multi tool as a final piece of prep work , I slid the tiles under the door jam and set them in place with spacers just like they'd be at install .

Then I used the painter's tape and marked eight inches on the tile as a reference for my one third overlap .

And I figured out the cut-off piece size that I'd need for the front of the door for the bond between the deer and the tile .

I needed to use an unmodified mortar .

Unfortunately , they only had an unmodified mortar in the gray at my local store .

It's better to use a white mortar when you're using light grout .

If you can get it , I mixed up the mortar , the same as before .

And while it was slacking , I cut the first half tiles , the size that would go against the tub .

And the most important joints visually here are gonna be the ones at the door .

So I started in the corner by the door in the tub and this made the install a little bit harder since typically , you would start on the far wall and work your way out row by row .

But I didn't want to risk a cumulative air or throwing off my joint at that last row by the door .

I worked the mortar into the waffle pattern .

I back buttered the large tiles to make sure that I had a good bond .

Then I set them in place to space the tiles .

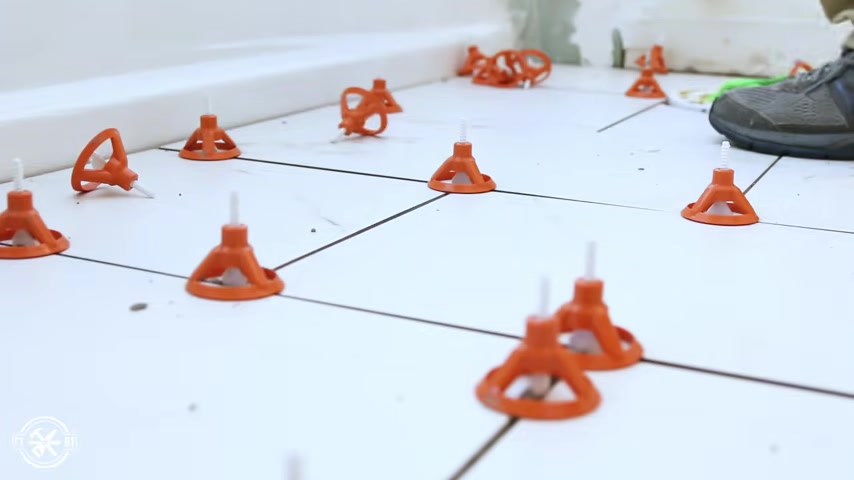

I use the rigid level mac system .

It's a spacer and lipid reducer all in one .

The teacher is a little tricky to get the hang of .

You really have to work the mortar into the waffle print to get it to fill the voids .

I used a half inch by half inch square notch trawl and work my way down the wall .

After I established that first row by the door on the wall , I worked my way across the front of the tub .

I cut the tiles the size as needed and I set them in place , wiggling them from side to side to collapse the mortar bed lines and get full adhesion on the tile again .

It helps to check here and make sure that you're getting good coverage when you're doing your tile placement .

And this is where the level max system comes into play .

There are spacers here for T joints , straight joints and four away joints .

And the spacers go under the tiles at the joint and the stems are threaded .

So the top pieces are screwed down as they're tightened , it pulls all the tiles flush with each other .

It's a really cool system .

I'll have a link below in the description .

You can find out more about them .

I worked my way to the fire wall and I needed to make the cuts for the toilet flash .

Now , at this point , we were in the heat of the moment and that Mastic was setting up so I didn't film it , but here's how I made the cuts , curve cuts can be notched out with a wet saw , but I use my angle grinder with a diamond embedded wheel .

And the key here is just to take light sweeping cuts and don't let the grinder bog down and dry cutting tile throws a lot of dust and chips .

So make sure you protect your eyes and your lungs too .

I went around the toilet and I worked my way out the door , laying the last full tile right in front of the doorway .

And the level max system really did a great job of keeping the tiles aligned and it sure beats the old days of using a carpet covered two by four to beat the tiles into place .

Now , after the mortar dried for 24 hours , I came back to snap off the stems of the spacers .

And this part right here is probably the most fun of the whole job .

A swift kick snaps the stems off of the spacers and the part left is under the tile and the tops can be unscrewed and used again .

I feel like this might be like a new therapy technique to relieve stress too .

I cleaned up the joints of any excess or loose mortar and then I vacuumed everything clean .

We went with a light grout to try and help the grout joints disappear and have the focus be the tiles .

I mix the grout by hand and with large format tiles , you really don't need a lot of grout at all .

I work the grout into the joints using a grout float at a 45 degree angle to the joint .

If you push the grout in parallel or perpendicular with the joint lines , then the edge of the float is gonna fall in and catch and it's just gonna pull the grout out .

After filling in all the grout , I rinse the excess off of the damp sponge .

You really want to ring the sponge out well , so that the grout doesn't get more water in it .

Because if you get more water , it can cause discoloration and weaken the joint .

I let the grout dry overnight and I came back the next day to buff off any grout haze .

And there were some tough spots there where I had to use a haze remover to get it off .

But it works well with a microfiber towel .

I used a grout colored cock to go between the tub and the flooring .

And then I reinstalled all the base boards and the floor turned out awesome .

It's a great focal point for the small bathroom and the light colored large format tile really makes this room feel bigger .

If you want to see the full bathroom remodel , it is gonna be right there when it goes live .

I've also got another video queued up for you right down below .

If you're not subscribed to the channel already , I'd love to have you as part of the team .

And until next time guys get out there and build something awesome .

Are you looking for a way to reach a wider audience and get more views on your videos?

Our innovative video to text transcribing service can help you do just that.

We provide accurate transcriptions of your videos along with visual content that will help you attract new viewers and keep them engaged. Plus, our data analytics and ad campaign tools can help you monetize your content and maximize your revenue.

Let's partner up and take your video content to the next level!

Contact us today to learn more.