https://www.youtube.com/watch?v=N1-Pxik-u4U

DIY Circular Saw Crosscut and Router Jig

What's up guys and welcome back .

Glad to have you today .

I'm working on the third version of the circular saw , cross cut jig .

Now , the main reason I'm doing this is because I got a new saw .

So when you get a new saw , you gotta make new tools and things in jig sports .

And I do think there's some huge improvement in this jig .

For example , you get a deeper cut .

You also can use your router on this just adjusting one of the rails that's gonna open up a whole world of opportunity .

Now , even though version two is really nice and I love the way that came out .

I actually love this one better because it's a smaller footprint and width wise .

And I love that you can just hang it up and store it somewhere .

So let's not waste any time .

I am gonna show you how it's made .

Now , as we get started , you're gonna need a sheet of plywood cut down for the base .

You'll also need a two inch seat channel AM track and also hold down clamp and a couple Rs down in the video description .

You can find a set of plans and links to some of the products I use in this video .

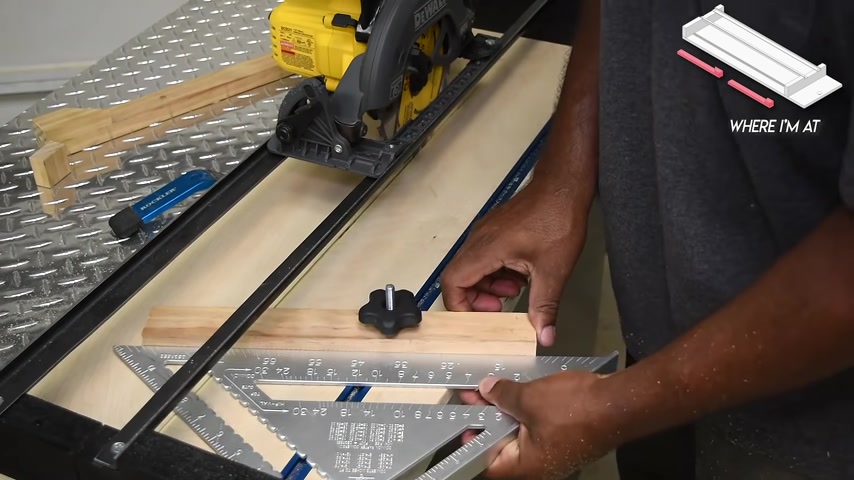

Now , I wanna make sure the piece of plywood I'm using is as straight as possible .

So the first thing I'm gonna do is draw a line across the entire width of it , then double check to make sure that I'm working off of a straight reference .

The first line I drew out was not as accurate as I would like it to be .

So I went to the opposite end and that was a lot better .

I then went on to set in the location for the T track prior to routing the track .

I attached a piece of scrap wood to my router guide and this helped a ton with control of the router .

I took off an eighth inch of a time until I was able to get down to 3/8 of an inch .

Now , this was about all I needed to do with the base .

So at this point , I can go ahead and sand it down and get that out of the way .

But the base down , I can go ahead and install the T track .

You can use shorter screws , but I only had three quarter inch screws for this application and I ended up cutting off the tips so that they didn't exit out the back to create the track .

I'm gonna rip down a two inch sea channel .

Now , I wouldn't get too concerned .

This doesn't have to be a straight rip down the middle .

The goal is to separate it , giving you two tracks that the saw can ride on .

Now , this is some really hard metal to cut through .

But the reciprocating saw and the Diablo blade , I'm using just slice right through this .

I'll link the tools and stuff I'm using down in the video description .

Now , after ripping the meter down the edge may be a bit sharp .

So you wanna take a file and or also a sander to just smooth that out a bit rather than sitting on top .

I'm going to recess the tracks down inside of the risers and I wanna make sure that these are parallel to each other and everything lines up .

So I'm going to do all the work at the same time .

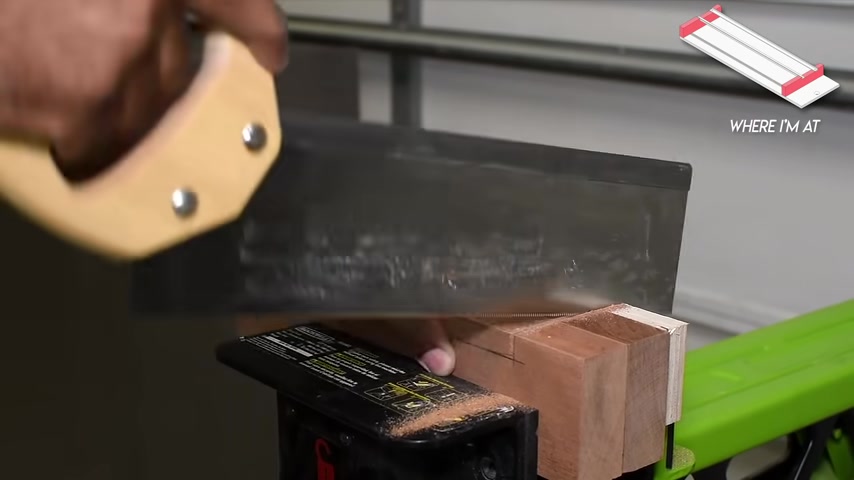

After cutting the outside line by hand , I then took a router and routed out the section .

My intention was to route out a section and also use some areas on touch so that I can use that to support the router base .

Unfortunately , I made some of the routed areas too wide and it couldn't support the router .

So I had to then switch over to the chisel to finish this job .

The piece of plywood on the back was to prevent the router from creating blowouts .

But since I went away from that , I ended up removing that so I can have clearance to cut out this section , this T track screw will remain in the track on the jig and I won't be able to remove it .

I couldn't make a opening wide enough so that the screw can slide off .

But I just don't want to weaken the support on the risers .

My solution to this is to channel out the area where the screw can sit at this part .

It is pretty important , especially if you want to take full advantage of the cut capacity within the opening .

And with this method , it allow you to slide the screw out of the way before you're permanently attaching the risers .

Make sure that you put the screw on the T track before moving on to secure the risers to the base .

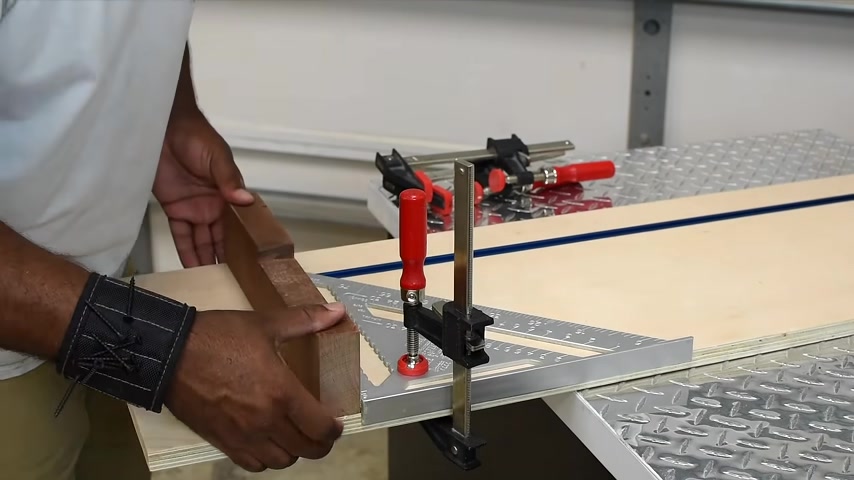

You wanna make sure you check for S square and add wood blue and also drilling in a few screws .

I'll repeat the same process on the opposite and while making sure it's squared after the glue has set up , I wanna place the tracks in the opening .

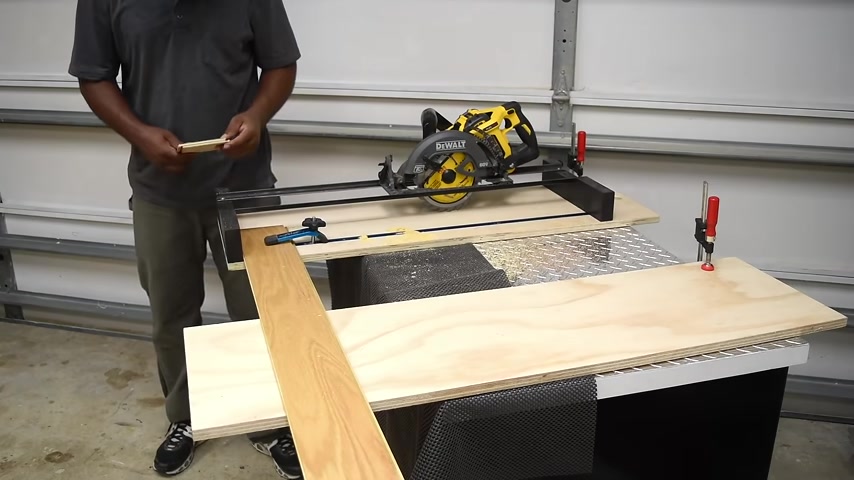

Then I'm gonna sit the saw on top of the track and make sure I get the proper spacing .

After drilling a hole in each track , I then install some wires to hold that end down .

While I move on to the next , I'm going to counter sync the screw holes so that the saw doesn't interfere with the head of the screw .

Each screw will be installed in a threaded insert .

And since this is a multipurpose jig , we're gonna then line up the new area for the router base .

And once these areas are drilled out , I can then install a couple more threaded insert .

I salvage these insert from some old furniture .

So I wasn't quite sure how big of an I should drill .

I ended up breaking a couple of them .

So if they're too hard to go in , just back them out , drill a slightly bigger hole and try it again , I'm gonna use black paint to finish off the metal track .

And also the risers , this should give it a finished look .

I only put on one thin layer of spray paint and make sure you don't get any paint inside the tracks with the tracks installed .

I'm gonna now drill out a hanging hole .

I don't know why , but I was a bit nervous to make the first cut , but it was a success .

I did run into a slight problem though is when you need to pull it back .

I have to hold on to the blade guard because it kept getting in the way as a quick fix .

I took a bracket and formed it to act as a stop .

I didn't want to drill a new hole .

So I'm gonna utilize the existing one there .

So I'll be using a wrench to install this bolt from now on now , if my tracks were wider at the bottom , I wouldn't need it because the track would catch that .

So the next thing I need to do is create some attachment so I can make minor cuts for this demonstration .

I'm gonna show you how to make two different angles .

One is cut to 22.5 and the other one is cut to 45 .

Keep in mind you can make as many as you like .

But I'm gonna show you the process , the smaller pieces will be attached to the longer piece you see here , which will reference off the straight edge set in a piece of wood to an angle .

So when it saw cut , it's automatically gonna cut at an angle .

I'm gonna utilize the bolt that's used for the hold on clamp as a pivot point , I clamp the two long lumber and drill the holes in the same section .

These boards can be in the length .

It just needs to extend past the cut area of the saw blade .

Now , to make this as accurate as possible , I'm gonna reference off my speed square .

Assuming that this minor piece is very accurate .

It's gonna force this board to sit at a 4 to 5 degree angle to glue this and finalize it .

I'm gonna use a speed square to help reference off of that and check as many things I can .

I'm gonna also take the knob and hold this down so that it doesn't budge , then I can take a clamp and lock this into place .

Notice how there's no gap in between the speed square and also the piece of lumber and this is consistent the whole distance .

After wrapping up the first moor attachment , I then took on the second attachment and wrap that up as the end are uneven and they're not lined up .

I'm going to cut off the excess and make sure that it's all the same to install these .

You're gonna line them up on the screw and swing it onto the track , then tighten it down .

I'd recommend you double check this with a speed square .

Every time you set up one of these attachment with this design , you can set the M attachment just about anywhere .

Now , you can go ahead and cut down the M attachment and I did this for both .

Now to hold your subject down , you can use a clamp or you can use a hold down clamp as I'm doing here if you have enough room .

Now , I was expecting this to be accurate because of all the pre set up , but I was really surprised on how accurate this was .

So let's look at a few of the possibilities that you can get from this jig .

Well , we now know that you can get 4 to 5 degree cuts , not only from 4 to 5 degrees but 22.5 and just about any angles you wanna create .

So one of the bigger improvement I've made versus the older jigs that was created was the cut capacity as you can see both measuring system .

This should give you an idea on how much you can cut .

Now , although this circular saw is a battery powered one .

It is a beast .

It has sliced through every material I've put in front of it .

Another cool feature to exercise is to safely make and half lap joints .

There's a lot of cool features to this jig .

Although it doesn't replace a table saw or a micro saw , you can accomplish some of the same task .

Now , routers tend to scare a lot of people .

So here's a really cool way to use your router and use it safely .

Make the necessary adjustment to your rails based on what was done previously , clamp your piece down and then you can simply make a data cut .

Maybe you need to flatten the board , you just put your board under here and then you just run your router back and forth .

So let's say you have a three quarter inch piece of plywood or something thinner .

What you could do is you could put another piece of material under it to bring that up closer to the router bit and this way you can work safely .

Alright guys .

So that is it for this one .

I am Glenn and thanks for watching .

If you're new to the channel , go ahead and subscribe .

I love to have you if you're planning to build this gig .

I love to hear what you'll be doing with this one .

If you need additional directions , then I have a set of plans , which is a great way to support what I do .

If you wanna see what I'm working on next , best way to do so join me on Instagram at more diy creators and that's it for this one .

Catch you on the next one .

Are you looking for a way to reach a wider audience and get more views on your videos?

Our innovative video to text transcribing service can help you do just that.

We provide accurate transcriptions of your videos along with visual content that will help you attract new viewers and keep them engaged. Plus, our data analytics and ad campaign tools can help you monetize your content and maximize your revenue.

Let's partner up and take your video content to the next level!

Contact us today to learn more.