https://www.youtube.com/watch?v=9-WYOK90KNo

How to Sand and Polish Epoxy Resin to a Mirror Finish - Step by Step Guide

Hey , I'm Carl from glass cast , and today I'm going to be going through the entire process of how to flat and polish epoxy to a mirror like finish .

Flattering and polishing just about anything takes patience , the right tools and a little bit of skill .

But polishing a poxy simply because of how tough it is is particularly hard , and I know how many people struggle with it just by how many customers we speak to in our technical support .

And so in this video , I'm going to be taking you through the whole process .

Step by step , we'll be looking at the tools , the materials and the technique to overcome classic problems like a dull finish or that shiny finish that still shows swirls and scratches .

Whether you're trying to get that perfect finish on a river table , a countertop , a casting or a jewellery piece , the information in this video is for you .

I'll be starting from a rough machine part just like this and begin sanding with 100 and 20 grit , abrasive , then progressively work through the grades right the way up to 1200 before moving on to buffing with a polishing compound and along the way , I'm going to be showing you loads of tips and tricks to help you get over your problems and transform your results .

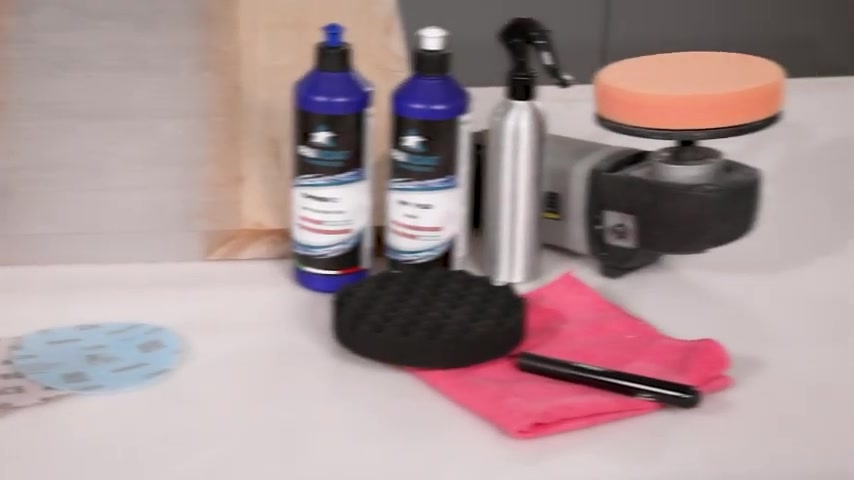

But before we begin , let's first take a look at the tools and materials that we're going to need .

So in this process we are going to be doing a lot of sanding .

And unless your project is very small , like a jewellery piece , an orbital sander is going to save you a huge amount of time .

Random orbital sander , often referred to as D .

A s , generally come in two different sizes 125 millimetres and 150 millimetres .

In both cases , sanding discs are attached to the machine by this hook and loop interface , meaning that if they are the right size , the most pads fit most machines .

Both of these machines are more than capable of getting you perfect results and are going to be far more effective than hand handing in terms of features .

The ability to connect both these machines to dust extraction is incredibly useful and allows you to sound almost completely dust free .

Throughout the video .

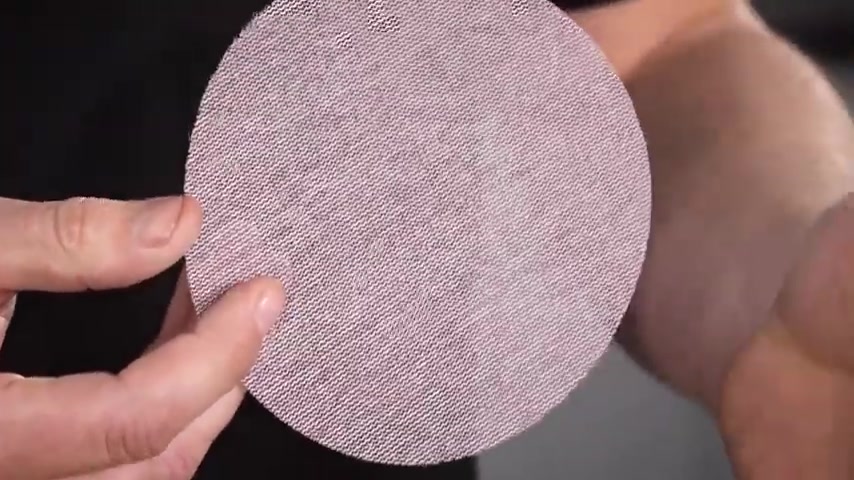

I'm going to be using the Merca sanding discs .

These are the types of discs that you'll find in a lot of professional workshops , and that is for a very good reason .

I'll be using the Abnet disc .

As you can see , these have a mesh construction , which stops them from clogging .

These are also the special ace version of the disc , which is specifically designed for hard materials .

Just like epoxy .

We'll use 121 82 4400 and 800 grit in the Arne before switching to Merca Galaxy for the 1200 grit .

We then have a polishing machine for the compounding stage .

Entry level polishes are fairly inexpensive .

The only features to look out for are variable speed control and a standard 150 millimetre backing plate .

With the polisher , we'll be using a hard and a soft foam pad and these compounds again .

The N W one that we're using here is a special grade of compound that is specifically designed for hard materials , just like epoxy .

I also have a marker pen and a spray bottle filled with water , and I'll explain their use to you shortly as well as the right tools and materials .

The other secret to achieving a perfect mirror like finish on your project is to follow a methodical process , and I do hate to say , but also spending a lot more time on each stage than you would otherwise imagine .

Now I might be tending to skip a step or work faster through the process than I am .

But if you do , you'll just defeat the point of this tutorial .

If you want the results , follow these steps to the letter , right , let's get started .

I've got here an example section of a river table .

But as I said earlier , the principles are exactly the same every time you need to flat and polish epoxy .

The only thing that might change is how course you need to start in this case here , with course machine marks left by the router , we need to start right down at 1 20 .

But if you're just flatting out light scratches in an epoxy counter , then you might want to start at 800 .

To get these lines out , I'm gonna do at least five passes with the 1 20 grip .

For obvious reasons , I'm going to speed the footage up for each step .

But to give you an idea of timescales on this sample piece , which is about a quarter of a square metre , each step is going to take around 10 minutes , sanding from right to left , overlapping the previous line .

We will systematically sand the whole piece , then will send perpendicular to this direction to ensure that the whole area is evenly sanded .

We're going to call this right to left top to bottom action , a single pass .

And , as I say , to ensure that we remove all of the lines left by the router , we're going to do at least five passes .

As you can see , all of the lines have been completely removed and the surface is perfectly flat .

So we're going to repeat this method of right to left up to down several times for each grip , with the addition that in between each pass , we'll mist and wipe away any dust , then draw on the epoxy with the marker pen .

This will help to identify when each pass is removed enough material , and it will help to keep the whole process methodical , so onto the 1 80 grip to make sure we get rid of all the scratches from the 1 20 grip , we're going to do at least five passes with 1 80 .

You can see that I'm not only sanding the epoxy , but also the wood sections , too .

It's important that you do sand over the whole area on a project like this .

Otherwise you'll end up sanding a dip into the resin section .

On the flip side of that , also be mindful that the wood will sound faster than the epoxy so you could move a little faster over the wood sections or apply a little less pressure on the wood .

If you find that on any pass , you are not removing the pen lines .

It means that you're not removing enough material .

This could be because you're either moving the sanda too fast over the epoxy , or that you need to apply a little more downward pressure on the saner .

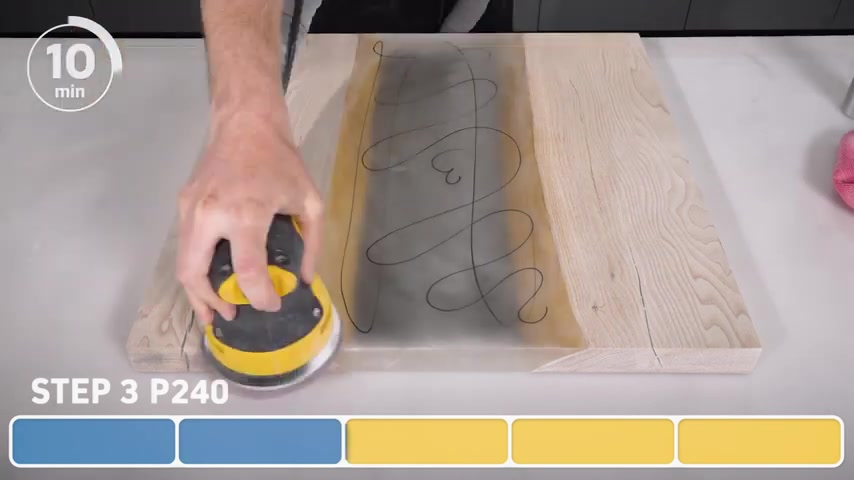

For the 2 40 again , we'll do five passes , which should be more than enough to remove all the scratches from the previous grit .

Although the abrine discs are incredible and not clogging , they can still occasionally clog .

If you see swirly pigtails like this , stop sanding immediately .

Clean the pad by folding and rolling between your fingers .

If you were to proceed sanding with a clogged disc , you could undo all the work that you've done with many of the previous grits .

However , if your disc is excessively clogged , it would be worth replacing it with a fresh one .

Also , on a point of how many discs you will need for this sample piece , I've used one disc from each grit .

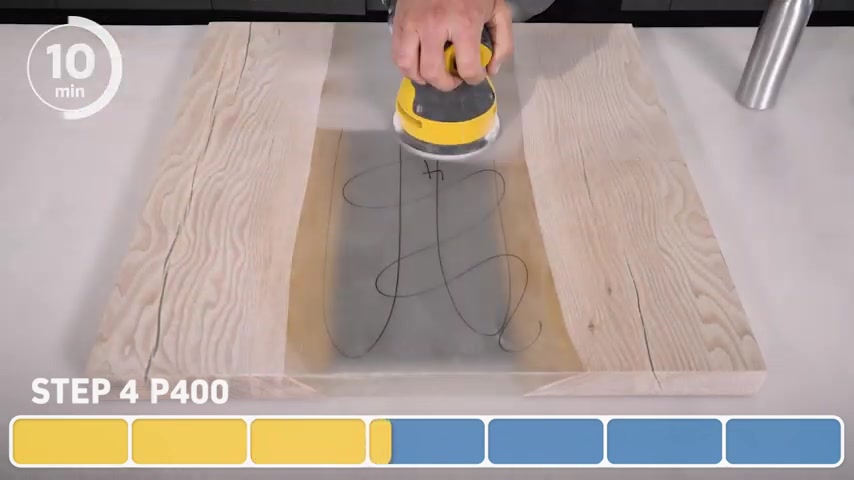

But if you're working on a larger river table , for example , you can expect to use multiple discs from each grit moving on now to 400 grip .

And for this step , we are going to be doing seven passes .

The reason that we're doing seven passes instead of five here is that we're technically missing out the 320 grip .

However , in my experience , it isn't always necessary to include the 320 grip .

An additional few passes with the 400 should achieve the same results , saving you time and having to buy more sanding pads than is necessary before moving on to the next step .

Now is a really good time to inspect the surface between the course of 244 100 grit .

It should be easier to identify if you've removed the deeper scratches from the previous grits .

If you can still see large , swirly scratches in the surface , you may need to go back and repeat a step .

As I can't see any .

I'm going to move forward onto the 100 grit again while we are making a big step from 400 to 800 .

And while it's perfectly fine to double up on the grits , we'll do seven passes to make sure all the scratches from the 400 are removed .

Although we are doing seven passes , it is still taking me about 10 minutes to complete this step on this piece .

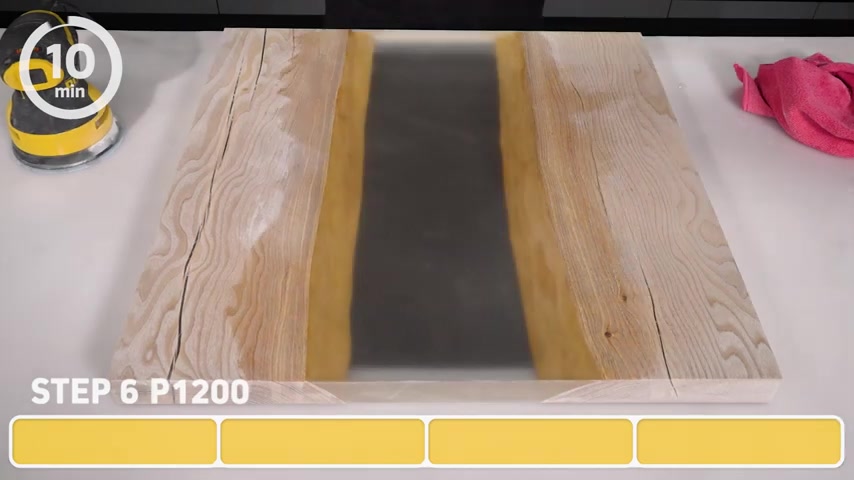

Now onto our finest grip .

We're going to switch to the 1200 Merca galaxy to help prevent clogging .

We're going to wet sand so lightly mixed with water in between each pass .

Four passes should be more than enough to remove the scratches from the previous grid .

Also , you'll notice that I'm not marking the resin for this step .

That's because the ink in the water could make an unintentionally stain the wood at this point .

Before we do proceed polishing .

If your project is a mix of both resin and wood , it's best to seal your wood to prevent it from being stained by the polishing compound .

On my sample piece , I'll apply a couple of coats of Danish oil .

So to recap , at this point , we've taken our epoxy surface from a machine finish right the way up to 1200 with the Sandra and abrasives .

And if you've got the right polishing Compound 1200 is as far as you need to go with the saner .

As I mentioned , we're gonna be using two polishing compounds the N W one and a top finish two .

The N W one is specifically designed for hard plastics , just like epoxy , and is quite capable of going from a 1200 grit to a good level of glass .

The top finish two is optional , but it will take that glass to a mirror finish , so we're gonna begin with the N .

W one .

And for this Corr compound , we're gonna use the medium hard pad , begin by applying a small amount of the compound onto the surface and then spread this around with the pad For this step .

We're going to be doing free passes .

I'd like to start off with the polisher on a slower setting while applying a bit of pressure to work the compound into the epoxy .

N W one is self diminishing , meaning that the more it's worked , the finer the grip gets .

One thing to keep in mind is to avoid overheating in the resin .

If you keep the polisher moving , you should be fine .

Being warm to the touch is OK , but if it does feel hot , then you should stop .

Allow the epoxy and the pad to fully cool down before you proceed .

Once the compound has fully diminished , I'll apply a little more and steadily increase the speed while being a little lighter with the pressure as the N W one is self diminishing .

Every time that we add more compound , we effectively start again from its most core state .

So to correctly use it , we need to make sure that for each pass , we completely work the compound to diminish it down until it's so fine it's pretty much disappeared .

We'll wipe away any leftover residue from the N .

W one before we proceed on to that final finish for the top finish .

Two .

We'll now switch to the soft pad .

Same as before .

We'll apply a few blobs and spread this around with the pad starting at a lower speed with light pressure will again work the top .

Finish two into the epoxy , then increasing the speed to both .

After the compound has completely disappeared , we'll add a little bit more and repeat .

Finally , we'll wipe off any residue , buff it with a microfiber and reveal our perfectly polished epoxy .

So there we go .

We have successfully flattered and polished this epoxy .

All of the hard work and attention to detail has really paid off , and we've been left with this glass like surface free of any ripples , swirls and scratches .

As I mentioned earlier , having the right products and materials really does make all the difference .

And so , if you need any of the abrasives , compounds or other products that are used in this guide , they're available to buy from the glass cast resin website .

If you have any questions or feedback , please leave a comment below .

I do always try and answer every question that we get .

And of course , if you have enjoyed this video , please subscribe and you'll get lots and lots of resin tutorials as we release them .

Thank you very much for watching , and I will see you next time .

Are you looking for a way to reach a wider audience and get more views on your videos?

Our innovative video to text transcribing service can help you do just that.

We provide accurate transcriptions of your videos along with visual content that will help you attract new viewers and keep them engaged. Plus, our data analytics and ad campaign tools can help you monetize your content and maximize your revenue.

Let's partner up and take your video content to the next level!

Contact us today to learn more.