https://www.youtube.com/watch?v=mecgFK2Le3U

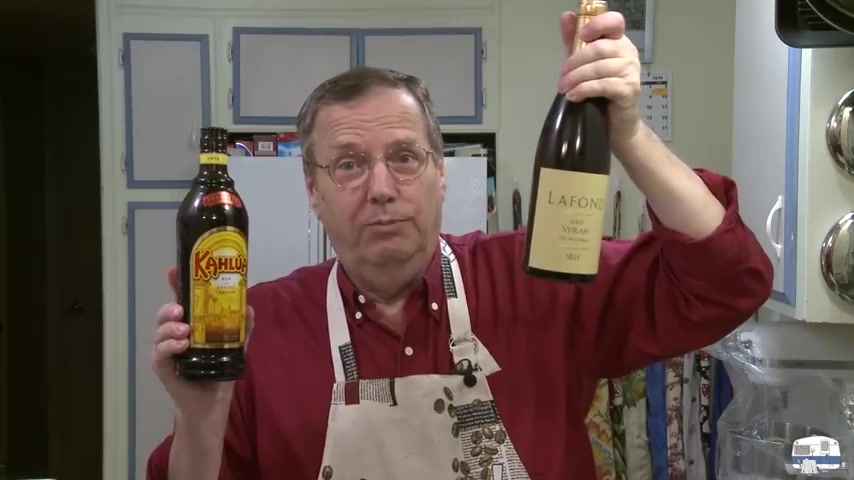

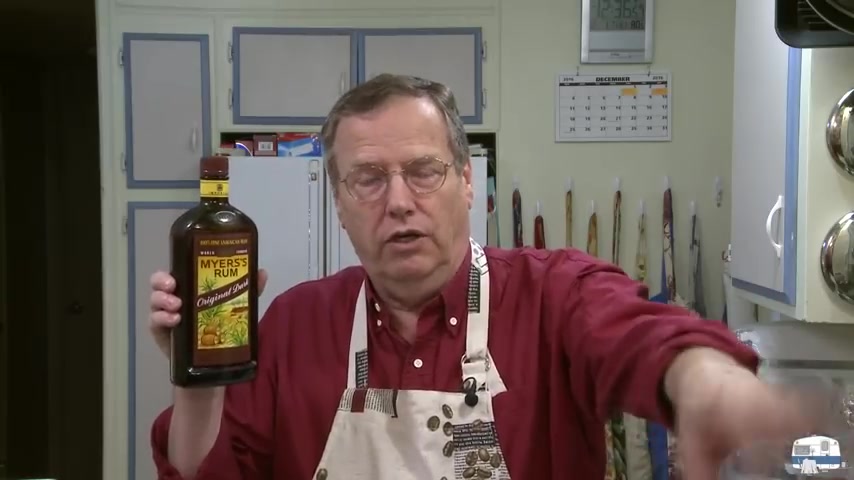

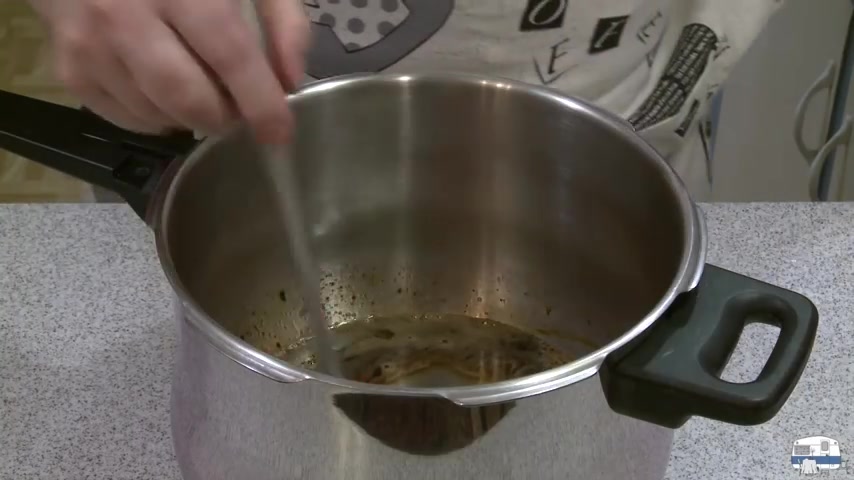

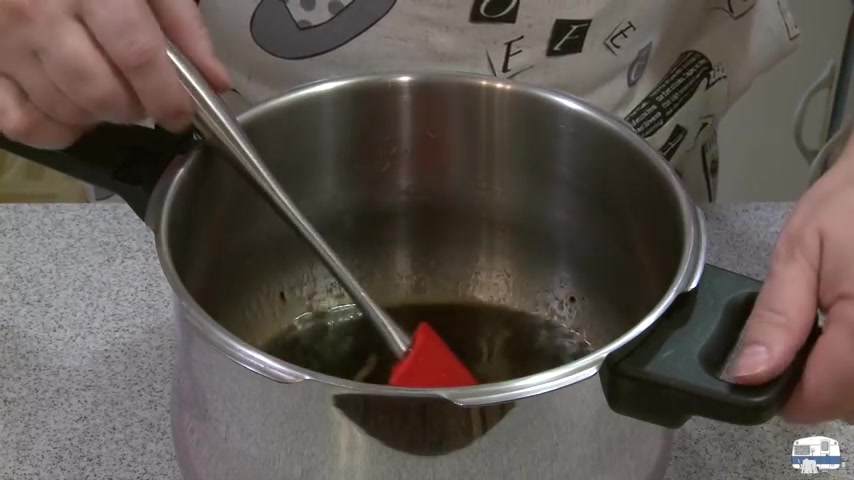

How to make Kahlua coffee liqueur at home

When you're making videos for youtube , it's all about doing something new .

So when we started designing , building and making plans for pieces .

A few months back , our focus was completely on doing just that making something new , new dresser , new rocking chair , new desk , new dining table , new dining chairs , new , new , new , and that's great .

That's the reason that I started making videos in the first place coming up with new things is literally my favorite aspect of everything that I do .

But sometimes it's nice to go back to something old couple that with the fact that we get a lot of requests for plans on pieces from our back catalog .

And this seemed like the perfect excuse to try something new , which is making something old anyway .

So that's what we're gonna do today .

Update and improve upon an old design and not just any old design , but literally the first thing that I ever designed and built .

And this was way back when I was taking a night class at a local community college way before I had any tools when basically I knew that I liked to draw furniture and I wanted to find out if I liked building it .

And if woodwork was for me , it was , anyhow , if you want to build this too , we're going to have links to the plans in the description along with all of our other pieces .

So check that out if you're interested .

OK .

So we've got all of our lumber rough cut into oversized chunks and now we're ready to start building .

And I guess if you're familiar with the old piece , one of the most common questions is probably gonna be in , what way is this piece any different ?

Or more importantly , better than the old one .

And there's a few that said , let's start putting this thing together and then we'll circle back to that .

I don't want to get too into the weeds this early .

All right .

So we're gonna start off by making our four legs .

And I always like to do this by cutting out a parallelogram that'll yield two legs .

So that means we need two parallelograms .

And you can see here that I'm using my Rockler cross cut sled , which I happen to think is perfect for this kind of cut that said it's not the only way to achieve this .

And you can certainly do it with any regular M gauge a mitr saw or just a piece of plywood and a few screws , which I'll demonstrate later in the video with our two parallelograms looking identical .

Next , we can mark out the finished shape of our legs and then we can cut those out .

And for this , you could use a tapering jig if you happen to have one .

But to circle back on what I just mentioned , here's how I can do it with a simple sled .

So basically , you'll get a piece of plywood , lock your fence in position and establish a cut edge .

Then we're gonna set up some temporary fences using plywood scraps on the sled so that we can repeat this cut as many times as we'd like .

And we'd like to do it four times .

At this point .

We have four tapered legs and four still rectangle shaped stretchers that we need to turn into leg subassemblies .

So the next step is gonna be cutting miters on all eight of these pieces .

And again , I'm gonna use a sled to get this done actually the same sled .

But this time , even though to make this cut , you could still use a Mitr gauge or a mita , I actually think that the sled is a superior method and we get deep into the reason and theory for this in chapter 4 , 14 of our plans , cutting the mitr joints .

And actually , since we get a lot of questions about what our plans include and how they're structured , we decided to upload this chapter as an example chapter and we talk a little bit more about it there .

So I'll throw a link to that in the description for anybody interested in finding out more .

All right , those pieces are looking good .

So now we can go ahead and assemble them and we can use dolls or dominos alone to do this and it'll be plenty strong .

But if you want to make them extra strong or if you like the look of it , we're also gonna cover how to make and install some splines using a simple table saw jig and we'll cover how to make the jig as well .

All right , I'm gonna let mine drive over night and then the next day I can trim and , or sand everything flush so that we can finish off the leg subassemblies by cutting the taper on the top edge .

And because I love them so much , I'm gonna use another Sledd to get this done .

So here I'm marking out the paper that I want to cut and getting my Sledd all set up .

Now , you might notice that when I actually go to cut them , you can see some domino mortises have already been cut in .

And that's because with just about any project , it's usually not best to completely finish off a piece and then move on to the next one and so on and so forth .

More typical would be to take something as far as you can and then set it aside and eventually come back to it at the proper time .

And that's because most pieces aren't sized .

Absolutely , but rather in relation to something else and to illustrate that point next , I'm gonna determine the thickness of my stretcher by referencing the taper that we just cut on the leg .

So if 100 people built this table , all of the stretchers would have unique thicknesses .

What ?

Oh , sorry , thick .

OK .

So we're jumping back in time here to before we cut our tapers and we're gonna cut the joinery for attaching our legs to the structure .

And for this joint , you could use Domino's dolls or pocket screws .

And if done properly , all should be serviceable .

And I know to some of you using a pocket hole might be sacrilegious .

But honestly , it's gonna be so inconspicuous within the project that I think it's a perfectly fine method .

All that said before we did anything .

Actually , before we even started this project , we made a test for this joint to make sure that it was going to be strong enough .

Should we test it ?

Mm .

I don't know .

I'll wait till tomorrow .

I let the glue here .

All right .

Fine .

I really want to stand on it though , man .

Yes .

Do you have or I don't know what he's worried about .

Yeah .

OK .

Back to reality .

Are you looking for a way to reach a wider audience and get more views on your videos?

Our innovative video to text transcribing service can help you do just that.

We provide accurate transcriptions of your videos along with visual content that will help you attract new viewers and keep them engaged. Plus, our data analytics and ad campaign tools can help you monetize your content and maximize your revenue.

Let's partner up and take your video content to the next level!

Contact us today to learn more.