https://www.youtube.com/watch?v=plv29i8gC68

How To Build a Modern Coffee Table (That looks Delicate, but isn't)

When you're making videos for youtube , it's all about doing something new .

So when we started designing , building and making plans for pieces .

A few months back , our focus was completely on doing just that making something new , new dresser , new rocking chair , new desk , new dining table , new dining chairs , new , new , new , and that's great .

That's the reason that I started making videos in the first place coming up with new things is literally my favorite aspect of everything that I do .

But sometimes it's nice to go back to something old couple that with the fact that we get a lot of requests for plans on pieces from our back catalog .

And this seemed like the perfect excuse to try something new , which is making something old anyway .

So that's what we're gonna do today .

Update and improve upon an old design and not just any old design , but literally the first thing that I ever designed and built .

And this was way back when I was taking a night class at a local community college way before I had any tools when basically I knew that I liked to draw furniture and I wanted to find out if I liked building it .

And if woodwork was for me , it was , anyhow , if you want to build this too , we're going to have links to the plans in the description along with all of our other pieces .

So check that out if you're interested .

OK .

So we've got all of our lumber rough cut into oversized chunks and now we're ready to start building .

And I guess if you're familiar with the old piece , one of the most common questions is probably gonna be in , what way is this piece any different ?

Or more importantly , better than the old one .

And there's a few that said , let's start putting this thing together and then we'll circle back to that .

I don't want to get too into the weeds this early .

All right .

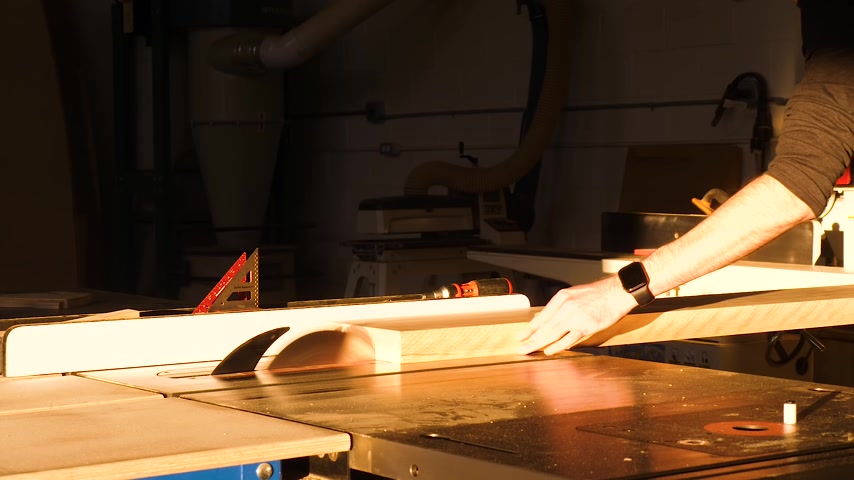

So we're gonna start off by making our four legs .

And I always like to do this by cutting out a parallelogram that'll yield two legs .

So that means we need two parallelograms .

And you can see here that I'm using my Rockler cross cut sled , which I happen to think is perfect for this kind of cut that said it's not the only way to achieve this .

And you can certainly do it with any regular M gauge a mitr saw or just a piece of plywood and a few screws , which I'll demonstrate later in the video with our two parallelograms looking identical .

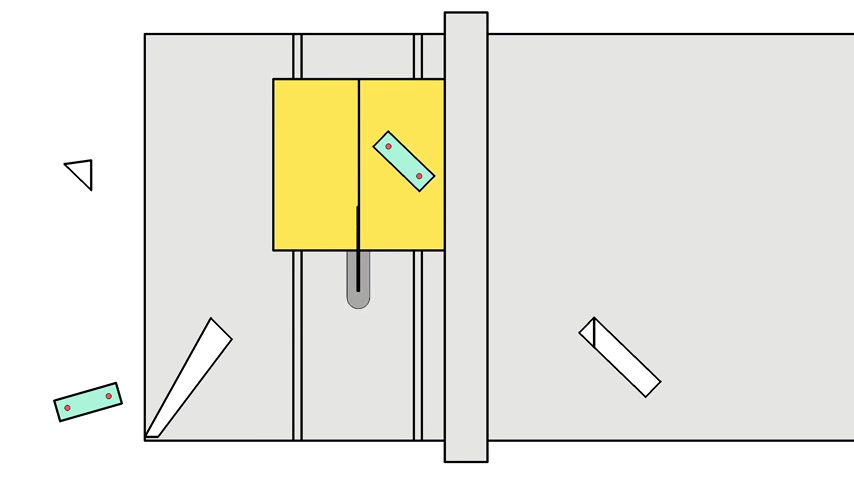

Next , we can mark out the finished shape of our legs and then we can cut those out .

And for this , you could use a tapering jig if you happen to have one .

But to circle back on what I just mentioned , here's how I can do it with a simple sled .

So basically , you'll get a piece of plywood , lock your fence in position and establish a cut edge .

Then we're gonna set up some temporary fences using plywood scraps on the sled so that we can repeat this cut as many times as we'd like .

And we'd like to do it four times .

At this point .

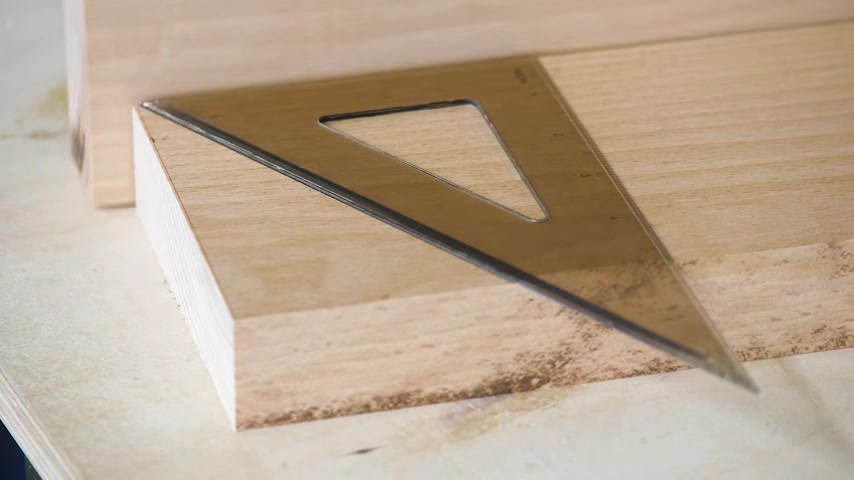

We have four tapered legs and four still rectangle shaped stretchers that we need to turn into leg subassemblies .

So the next step is gonna be cutting miters on all eight of these pieces .

And again , I'm gonna use a sled to get this done actually the same sled .

But this time , even though to make this cut , you could still use a Mitr gauge or a mita , I actually think that the sled is a superior method and we get deep into the reason and theory for this in chapter 4 , 14 of our plans , cutting the mitr joints .

And actually , since we get a lot of questions about what our plans include and how they're structured , we decided to upload this chapter as an example chapter and we talk a little bit more about it there .

So I'll throw a link to that in the description for anybody interested in finding out more .

All right , those pieces are looking good .

So now we can go ahead and assemble them and we can use dolls or dominos alone to do this and it'll be plenty strong .

But if you want to make them extra strong or if you like the look of it , we're also gonna cover how to make and install some splines using a simple table saw jig and we'll cover how to make the jig as well .

All right , I'm gonna let mine drive over night and then the next day I can trim and , or sand everything flush so that we can finish off the leg subassemblies by cutting the taper on the top edge .

And because I love them so much , I'm gonna use another Sledd to get this done .

So here I'm marking out the paper that I want to cut and getting my Sledd all set up .

Now , you might notice that when I actually go to cut them , you can see some domino mortises have already been cut in .

And that's because with just about any project , it's usually not best to completely finish off a piece and then move on to the next one and so on and so forth .

More typical would be to take something as far as you can and then set it aside and eventually come back to it at the proper time .

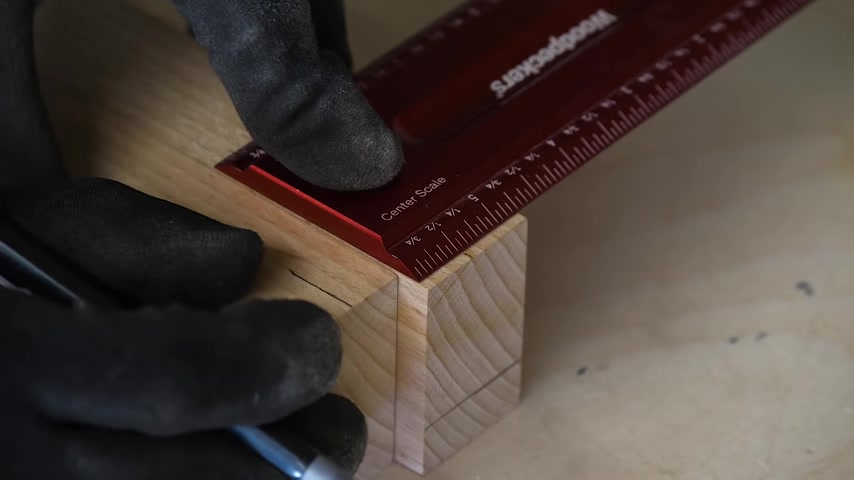

And that's because most pieces aren't sized .

Absolutely , but rather in relation to something else and to illustrate that point next , I'm gonna determine the thickness of my stretcher by referencing the taper that we just cut on the leg .

So if 100 people built this table , all of the stretchers would have unique thicknesses .

What ?

Oh , sorry , thick .

OK .

So we're jumping back in time here to before we cut our tapers and we're gonna cut the joinery for attaching our legs to the structure .

And for this joint , you could use Domino's dolls or pocket screws .

And if done properly , all should be serviceable .

And I know to some of you using a pocket hole might be sacrilegious .

But honestly , it's gonna be so inconspicuous within the project that I think it's a perfectly fine method .

All that said before we did anything .

Actually , before we even started this project , we made a test for this joint to make sure that it was going to be strong enough .

Should we test it ?

Mm .

I don't know .

I'll wait till tomorrow .

I let the glue here .

All right .

Fine .

I really want to stand on it though , man .

Yes .

Do you have or I don't know what he's worried about .

Yeah .

OK .

Back to reality .

And if you're worried about the pocket hole version , don't be , yeah , like this in this way is more than OK , let's turn our attention to the top for a minute .

And if I'm being honest , this was kind of grunt work .

So I'm gonna go ahead and have my shop assistant take care of it .

And while he's doing that , I'm gonna thank simply safe for sponsoring this video .

So simply safe is the easy to use customizable home security system that's free from contracts and hidden fees and gets delivered right to your door .

So you can set it up simply and all on your own .

And once you have your home is professionally monitored 24 7 .

So if anything happens , they call the police .

I've had my system for two years and it's been about as easy as can be .

The setup is super simple and the fact that the systems are customizable makes it perfect for any situation .

We started with window and door sensors , glass break sensors , cameras and the basics and have since expanded to include the video doorbell and the simply safe lock , which has been really cool .

It does things like verifies that our house is locked using a timer and lets us keep track of who comes and goes and even set unique codes for special circumstances .

Now , I'm not an expert when it comes to setting up a security system .

So something that really gave me peace of mind was using the test mode .

After I set everything up , I could enter that mode and have the base station confirm that it's receiving signals from our various sensors .

That way I know it's working before it's too late .

So if you're in the market for a home security system or even if you already have a home security system that you think could be better , you're up to yourself to check out simply safe , just head over to simply safe dot com slash four eyes or better yet .

Click the link in the description , right ?

Thanks and safe .

Now , let's get back to the building .

So at this point , if you used pocket holes , then obviously you've already assembled everything .

But if not , that's gonna be the next step .

And since this is pretty straightforward , actually , real quick before we do that , let's test how strong this joint really is .

Doesn't do anything .

But if we both stand on it , I feel like that is not gonna break it .

OK .

I did nothing .

Maybe jumping a little bit more on it .

Oh , I heard something .

Oh Yeah , we got a little crack .

We got a little crack in the , oh , it's so it's not even the joint .

It's actually doesn't surprise me .

It's actually the piece of wood split , the joint is still fine .

So , all right .

So if you're wondering how strong the joint is , it's stronger than the wood .

Now , it's probably a good time to circle back to that question that I posed early on in the video and that was in , what way is this piece any different or more importantly , better than the old one ?

And as I said , then I think there's a few .

So subjectively , the geometry is just better when I first started designing , I had this mindset that all angles needed to be whole numbers and usually in increments of five .

But as I've progressed , I've realized that oftentimes cutting arbitrary and unknown angles isn't really any more difficult than cutting known and whole number angles .

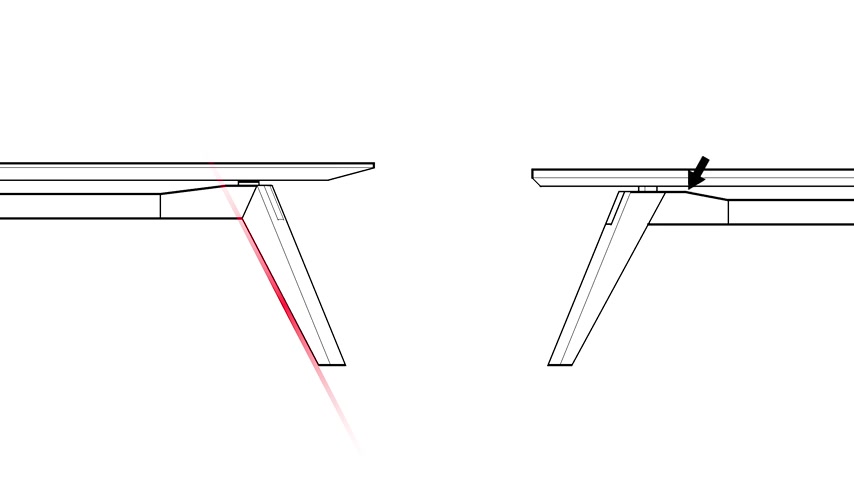

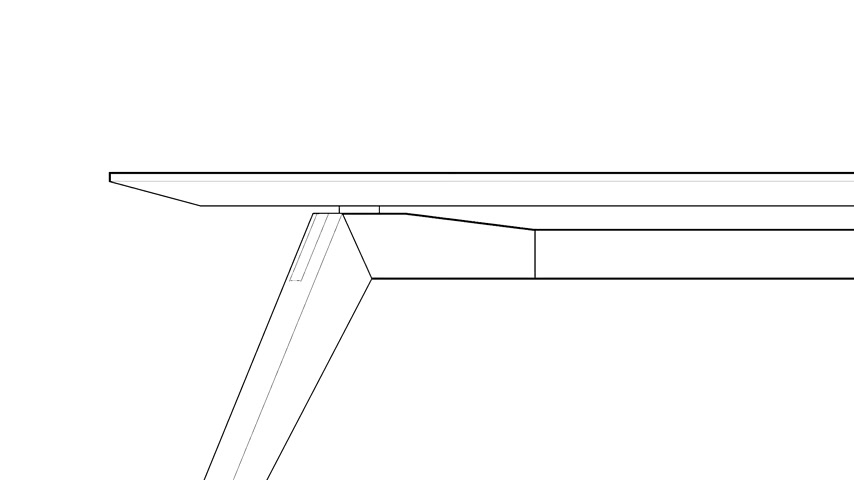

So take this portion of the table , for example , what's more important to my eye now is the convergence of points see how the angle of the top changes , right , where the continuation of this line would intersect .

I like that .

Whereas in the past , the angle changed kind of arbitrarily all because I wanted this angle to be a whole number .

I also happen to think that the blind Mitter is a nicer looking joint and probably stronger for this application than the half laps that I've used in the past .

And I also like the fact that they look the same when viewed from either the long or short end of the table .

Whereas with the half laps from one view , the leg is elongated and from the other , the stretcher elongated .

So you had to choose another .

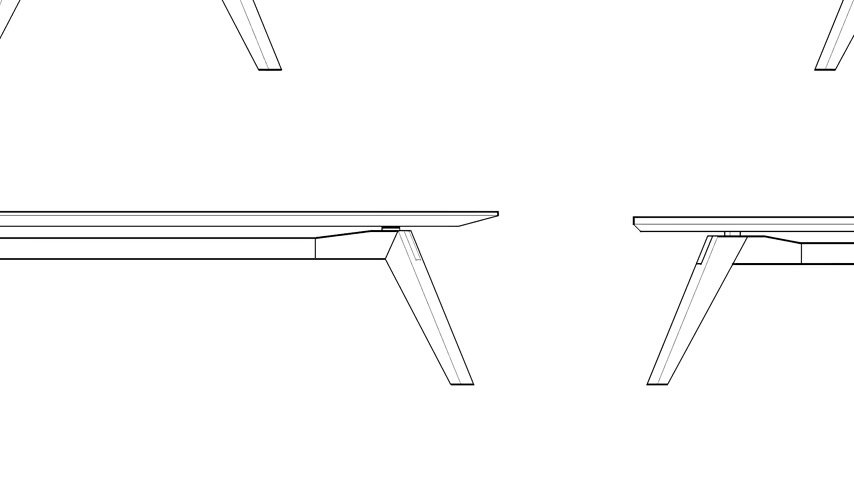

And arguably the biggest change is the overall dimensions of the table .

So my original design is for a pretty low table .

Now , I happen to like really low and long furniture , but I also know that I might be in the minority .

So in the plans , we have dimensions for this table as well as a taller version that's more on par with standard dimensions that you might find .

Now , there's a lot more differences that I don't have the time to get into here .

But the biggest improvement in my eye from a production point of view and this was really important to me because the whole point of making plans is that it's relatively easy for anybody to replicate .

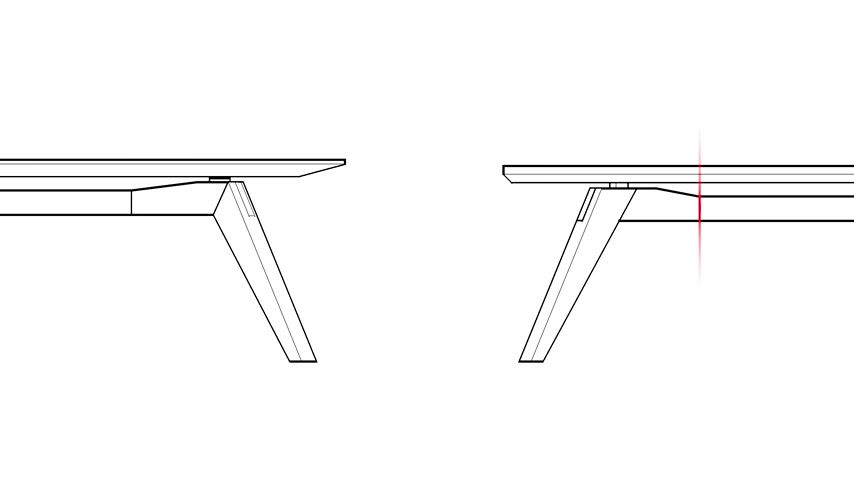

Is this intersection here in the past ?

The way that I cut this left almost no room for error .

Not only did the thickness of the stretcher have to perfectly match the thin end of your taper , but the width of the stretcher also had to come out perfect .

So that 45 degree cuts along either edge would perfectly match the thickness of your leg pieces .

But in the new design , the only necessary match is the thickness of the stretcher in relation to the end of your taper .

Meanwhile , the thickness of your leg pieces and the width of your stretcher can be anything reasonably close and we make it easy to refine everything after the fact .

So it's basically the difference between trying to perfectly nail one thing versus trying to perfectly nail two things simultaneously , which contrary to intuition is more than twice as hard .

OK .

So the way that we're gonna attach the two together is using these exposed floating tenons .

And this is a detail that requires a fair amount of work and that you really only notice from low angles .

So if you want to simplify things .

You could definitely skip this , but I happen to think that it's a pretty nice detail .

So here's how we're gonna do it .

Well , I guess first you could certainly do this with a drill press and a chisel or even a domino if you have one .

But we're gonna cover making a simple jig that kind of turns our router into a domino and then use that to cut mortises in both the base and the table top , which will be the same size and then we can make ourselves some floating tenants to attach everything .

Now , before we make these attachments permanent , we're gonna cut an edge detail on the underside of the table top .

And this is another place where I think the design has improved and to make this cut , we're gonna use the same jig that we used to cut our splines .

But if making this cut scares you , there are other albeit slower ways to make this cut or you could just go for a regular 45 degree chamfer instead another optional quote unquote improvement that we're gonna make is the addition of this thumbnail profile on the back side of our legs .

And Sean and I have been using this detail a lot , I think because it's a great combination of rounded but still crisp and it just really helps the piece to feel complete .

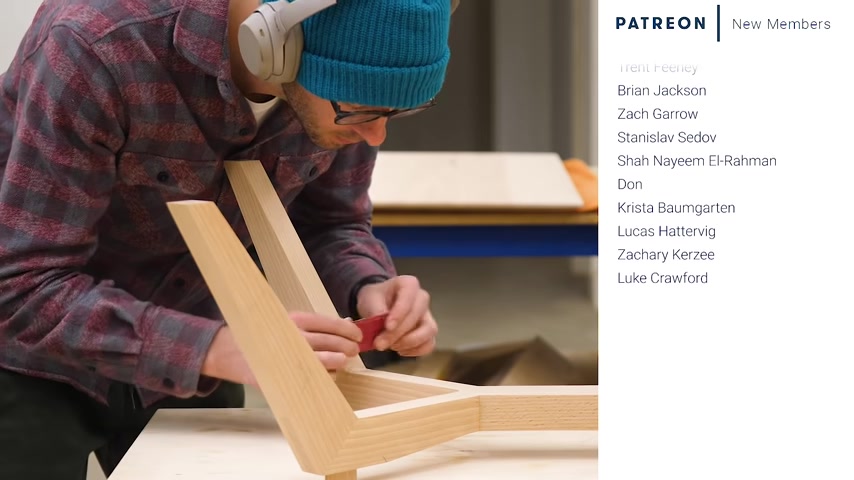

Now , you should see some names scrolling across the screen and those are the names of my new Patreon members .

So first and foremost , let me say thank you all for the support .

I say it time and time again , but it's true , you all are integral to enabling me to be able to do this .

So thank you .

And hopefully you should have received your t-shirts by now .

But if not , they're in the mail and also don't forget that anybody at the $10 tier gets a $15 discount code for plans just because I hate the idea of somebody double paying for something .

So if you want a t-shirt or a discount on plans or more importantly , if you just like the content and want to support the show , I'll have a link to my Patreon in the description .

So take a look at it if you're interested .

And as always , no pressure if you're interested in checking out these plans or any of our others , definitely give us a look and don't forget the example chapter that we uploaded .

If you want to have a little preview of what our plans look like in any case .

Thank you for the support and thank you for watching and we'll see you in the next one .

Are you looking for a way to reach a wider audience and get more views on your videos?

Our innovative video to text transcribing service can help you do just that.

We provide accurate transcriptions of your videos along with visual content that will help you attract new viewers and keep them engaged. Plus, our data analytics and ad campaign tools can help you monetize your content and maximize your revenue.

Let's partner up and take your video content to the next level!

Contact us today to learn more.