https://www.youtube.com/watch?v=bwFMmBuhKe0

PVD Black Chrome Professional Wheel Restoration! Step by Step Walkthrough

What is up guys ?

So Canadian writer , I'm with John from Union Ri again .

And today we're gonna be doing a full wheel restoration using PV D black chrome process .

So we're back at Union Rim with John and I have my 2006 Lexus I S3 50 wheels here .

They've taken a beating lots of curb rash , lots of damage .

And I'm excited to get these refinished completely in this black chrome PV D process .

This is going to give me the look of chrome , but with a lot of additional added benefits .

That's important for me with my daily driver .

Number one , the color is going to be virtually identical to regular chrome .

It's going to be equivalent is going to have an equivalent or better abrasion resistance and additionally , 30% improvement in wear resistance .

So all of these things are very important to me owning a daily driver .

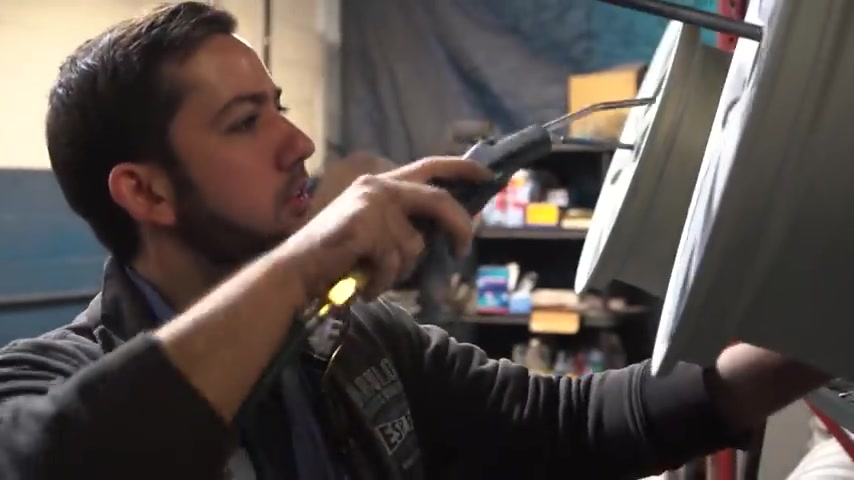

And the first thing that you're going to see John do important for any finish , including this PV D chrome process that we're going to go through just like powder coating , you need to sandblast the wheels .

This is extremely important .

This is going to give that wheel , the right finish for the powder coating and PV D chrome to actually adhere onto the wheel properly .

On top of that , this sand blasting process is going to allow John to actually visually identify any other nicks or scratches or maybe even potential dents in the rim so he can go ahead and make those fixes .

So John takes time on each one of these wheels .

Once they've been sandblasted , he's checking them out .

Any nicks and scratches .

Do I need to add any more metal ?

Do I need to send anything down ?

It's important to get the finish here as perfect as possible because this part is going to impact how the final product looks after all of the different layers get applied onto the wheel .

I just took a paint night class recently and really this is exactly like an artist working on his craft and this is his mold of clay or this is his canvas and he's just making this beautiful wheel .

This is automotive craftsmanship and design and beauty that he's creating , which is really amazing .

So you guys see in John's shop right now , he's got two big manufacturing ovens here that are designed specifically for these wheels and rims .

And this entire room is designed just for the powder coating process .

So the first thing that he's gonna be doing is going ahead and actually baking these wheels .

This was a term that we talked about previously in the powder coating video , he's basically going to be hot flocking these wheels very important when you're working on a wheel like this , the finish is gonna be extremely critical .

The prep work that you do is gonna be extremely critical to how the finish turns out .

So you know , making sure there's nothing on there and then continuing with the powder coating process here to start .

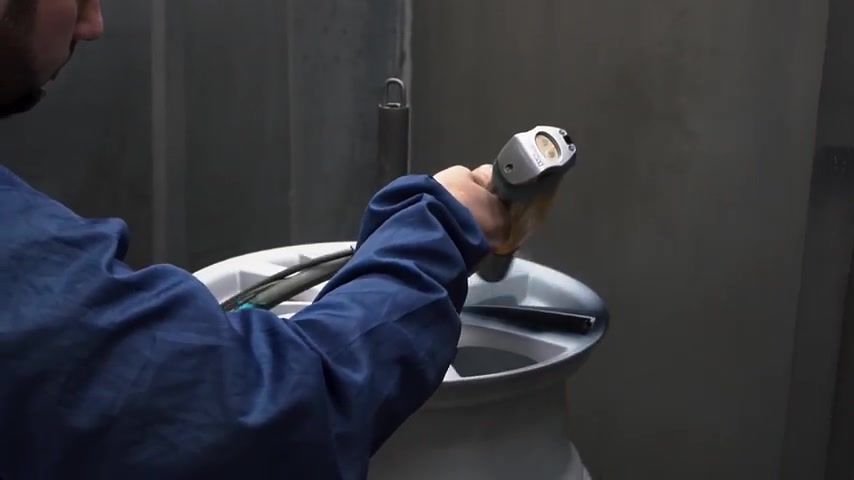

And you can see right now John is making sure that the entire area is completely clean of any contaminants including himself .

So this is gonna be applying the black base coat that we want on this wheel for the look that we're going for .

And this is an amazing to see a professional , his work in the right environment .

This is not something you can do in your backyard or in your garage at home to do it the right way , John does it the right way .

I'm so impressed with my Audi R eight wheels .

Um had those for about a year and a half now and unbelievable , they look stunning and I can't wait to see how these wheels are gonna look once they go through the full process .

But you can see in these video clips already , just this black base coat .

This powder coat looks absolutely beautiful on this wheel .

Now , once John's actually done this and applied them to all of these wheels , he's going to put them back into the oven to heat them up and once they come out .

They're going to cool down to room temperature .

That's when we'll go over to the actual PV D room and apply the PV D coating onto the wheels .

As the second layer , we've stripped the wheels down to bare metal .

We de grease them , took off all the curb rash , we sand , blasted them , put them in the oven , we heated them up , we sprayed them hot , we let the powder flow , put them in the oven and then we're gonna fully cure them and then is go to the vacuum chamber .

After to apply the metal layer , the wheels are fully cured at around 200 Celsius or 400 Fahrenheit .

So the powder melts and flows and fully cures the metal layer adheres properly that way as well .

After that step is done , we can apply the metal layer and then we put the clear coat on top .

Also powder coated after the wheels come out of the oven , they're going to cool down to room temperature .

We're going to apply a very , very , very thin film layer of metal .

It's actually so thin that to give you a comparison , a human hair on average 0.5 millimeters thick .

And the metal layer that we're putting on is 0.3 millimeter thick .

So you can imagine how thin it is .

You know , if it's just a piece that's going to be hanging in a room or you know , no one's going to touch it , then it's good to go .

You don't need to put any clear coat on it .

But since this is road use and it's a wheel and all that stuff , you have to protect it somehow .

And in this case , we will be getting powder coating .

So essentially in the end , you're getting a powder coated finish , which is known to be a very , very , very durable finish .

Now , at the same time , we don't have to do just metal , we can do plastic pieces .

So we've done center caps , we've done dashboard trims .

We're able to apply it on toys , believe it or not anything .

Basically that can fit in the machine and can be painted and can be powder coated if it's metal and you can also do a lot of different colors as well .

You can do candy colors , you can do tinted clears , you know , in this case in K Rogers case , we're doing black chrome , which is a very popular finish and it comes a lot on the O E M Jeep Grand Cherokee Wheels now , vacuum metal or PVD chrome , the positive side to it because it's a powder coated finish and you're applying an epoxy based powder first .

It pretty much will never pit or peel maybe 10 years from now or something where you might notice some tea and wear .

You're like one of the only shops in Canada that does this .

That's right .

So , so the process as a start up is very , very expensive from a business point of view .

Um So the , there's only , maybe we're , I , I'd say we're the only company in Canada or the first company in Canada that uh is able to apply this on wheels .

Now , there are other companies out there that do it on uh like plastic trims and stuff like that .

But you , you , you need a big vacuum chamber to be able to do wheels and all that stuff .

So again , we're the first one in Canada and in all of North America , the top of my head , maybe there's about five or six companies that do this , the vacuum meals or the PVD chrome onto wheels .

Is there special machinery ?

Is that why there is so little people that are doing it ?

Yes .

So you need , you need a vacuum chamber .

You need actually a lot of energy and a lot of juice to power up these machines to set something like this up is not just your average Joe that does , you know that can start powder coring in the back of a garage .

You need the proper equipment .

You need the spray rooms , you need , you need a dust free environment because again , PVD chrome in general , any low imperfection in the metal or the paint job or the powder code job , it will get magnified .

What is the special process afterwards ?

After it's so basically , now we just wait for them to cool down to room temperature , we load them up onto the machine .

We got to create a vacuum inside the chamber where we drop the pressure and that creates an environment where we can apply a pure metal layer onto the substrate .

In this case , the wheels and that gives you a high dense chrome finish .

Get finished .

It's like super durable .

It's not gonna get pitted orded .

Yeah .

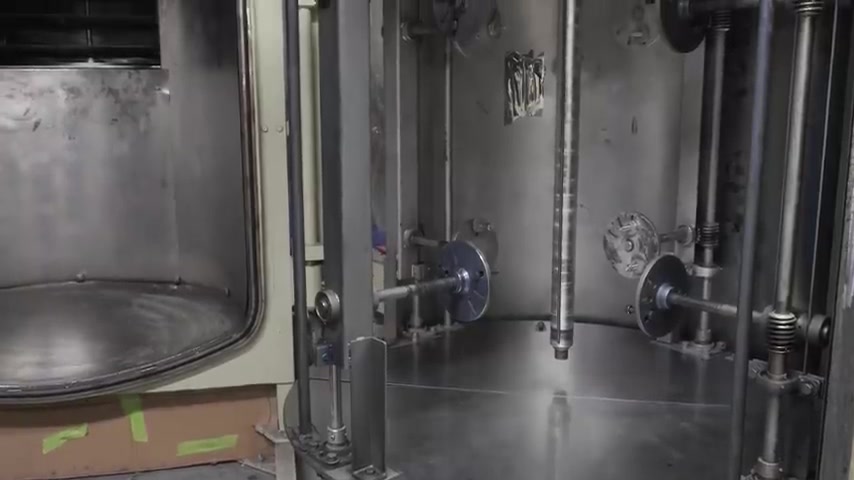

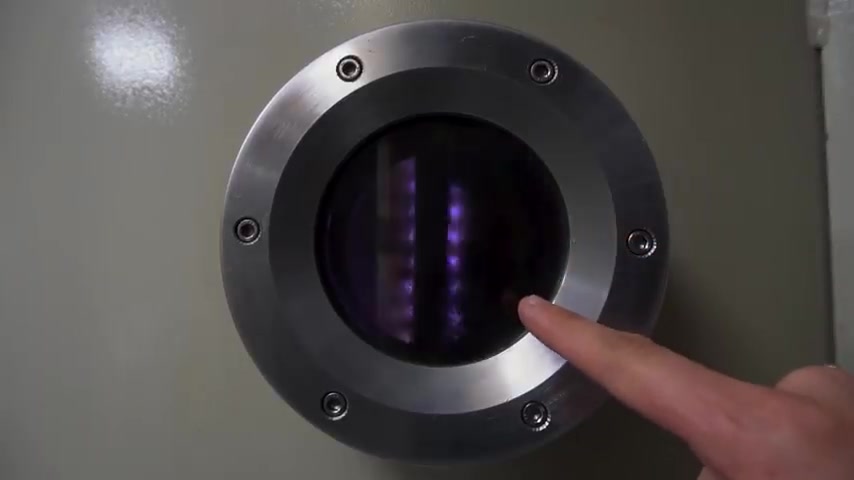

So here we're in the room where we apply the PV D uh chrome finish .

There's a door here where we're gonna open up and we're gonna load the wheels in there and it does this thing .

It applies its uh the metal layer and then we take it out and put the clear on top .

Um Let me just start with the machine .

This door was pressurized .

So I depressurize this so I can open the door .

This comes out just like your car , you hang it , you screw it on , so it doesn't fall over , put it back in , you load up the machine and just like a mirror , go around , it spins and it applies the chrome .

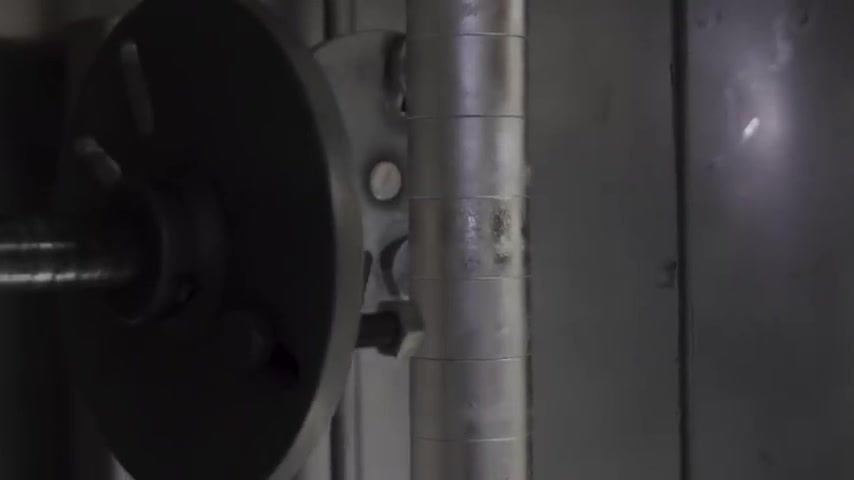

This here where you're looking at right now is actual chrome .

It's called the target as it spins and heat source is applied , this is more or less called sputtering .

In this case , it creates a plasma and atom by atom .

It applies , it goes onto the wheel and that's why you get a very uniform finish .

So now you're seeing John take out the wheels from the oven .

They look absolutely stunning already and we haven't even finished the process .

What's really cool about this is that not only when you apply this PV D chrome onto the wheel , but you can save up to 50% on the coating weight alone .

That's one of the other beneficial items about PV D uh chrome or the PV D chrome process is that it's going to be giving you a durable air protection .

On top of that , it's going to be saving you weight , you know , which can add to an overall increase in fuel efficiency for your vehicle .

All right .

So now we have the wheels loaded up .

We're just going to close the door , start pumping the air out and to create a vacuum .

Yeah , that's pretty much it .

So we'll close the door now .

So now we're gonna create a seal and that's it .

Now , we just gotta wait .

Can rider is gonna try to , he's gonna try to open it .

Oh , wow .

And there's no lock , you lock this .

It's just the pressure , it's just the pressure .

Exactly .

Wow , that's crazy .

So , you know how much pressure .

So it's just basically sucking out all the air , all the contaminants , all the atmospheric air so that we can apply uh pure Argon gas inside the chamber .

After , if I didn't mention it before , I'll mention it again .

This is definitely not something you can do in your backyard or in your garage .

You can actually see the alloy heating up in the middle and it's sputtering and it's sputtering itself all over the wheels to give it that coating , which is so cool to see .

I like that .

They included the sight class in this and now you can take a look at these wheels .

They turned out absolutely beautiful .

Look at that finish .

It's almost unbelievable that to see it happen in front of you um putting in this chamber and there's no byproduct whatsoever from this process .

And the wheels come out with this beautiful chrome look really looks pretty already .

So take a minute and just enjoy the beautiful shine and the beautiful looks .

Now , the next step and the final step is going to be adding that final layer of protection , the tinted clear over these wheels to give it its final look .

But this already looks stunning .

I think any stage during this process , we can go ahead and say these would look great on the Lexus , but this is going to give it that last layer of protection .

We talked about the importance of sandwiching this PV D chrome finish in between two powder coated layers .

And that's what we're exactly what we're doing here .

John's putting them back in the oven , he's gonna bake them once this finish sets , it's gonna come out and we're gonna see the final product .

Take a look at this .

This looks so so good .

I cannot wait to get this on the Lexus .

The finish is absolutely perfect .

You can see the huge difference from before and after John's done such an amazing job with these wheels .

I can't wait to put them on the car if you haven't already , make sure you guys subscribe to the channel to see these wheels on the Lexus .

I have to give a big shout out to John from Union Ram .

Him and his team have been amazing to work with .

They did such a great job on my Audi R A E V one wheels and they did such a spectacular job again with this PV D black chrome process and finish .

He's done on my Lexus wheels .

Can't thank him enough if you have any questions , make sure you leave down in the comment box down below .

Give this video a like make sure you subscribe .

It helps so much for the channel .

There's over 25,000 of you guys subscribe .

Thank you guys so much .

Reach out to John from Union .

They're definitely the best in the G T A .

I wouldn't trust anyone else .

This guy is a true pro you can see by his facility you can see by the care that he takes during the process .

Really looking forward to putting these on Alexis and I will catch you guys in the next video .

Are you looking for a way to reach a wider audience and get more views on your videos?

Our innovative video to text transcribing service can help you do just that.

We provide accurate transcriptions of your videos along with visual content that will help you attract new viewers and keep them engaged. Plus, our data analytics and ad campaign tools can help you monetize your content and maximize your revenue.

Let's partner up and take your video content to the next level!

Contact us today to learn more.