https://www.youtube.com/watch?v=ww6huRWr_YI

How To Fix Sunken Outlet _ 2 Easy Options

It's a very common problem I run into in both old homes like this one , which was built in 19 oh four or even a newer home that you just put some backsplash up and now you have outlets or light switches that are sunken back into the wall and it just doesn't look good .

This can also be a safety issue and you might now be out of code compliance .

So there is the easy way to fix this and there is also the safe way that you might need to consider depending on your scenario .

And sometimes these are actually used in combination with each other depending on your situation .

So let's go ahead and take the wall plate off and show you what is the root cause of this type of issue .

In addition , I'll give you a few other tips along the way , which will help you navigate your specific scenario and make this a one trip to the hardware store project for you .

So let's jump into it .

So go ahead and remove the wall play and now that we're opening things up , obviously , we want the power to be off .

So I've hit the circuit breaker .

And I'll confirm that with my outlet tester noted led s lighting up for the bottom and the top .

So we're good to go .

So the two things going on here , which is causing my problem is one , the box is offset too far in .

Now , this might originally been set incorrectly when the house was rewired years back or the wall has been modified over time .

And then that has built out the surface on boxes such as this like a new work box , you have reference tabs on the bottom and top , which would set against the stud .

And that's gonna give you a 3/8 of an inch offset protruding past the stud .

So when you put your dry wall on your outside surface is only gonna be sunken in 1/8 of an inch and that's gonna give you the finish look you want .

But additionally , if you're doing back splash , you can offset with these reference marks .

These reference marks are 1/8 of an inch .

So it starts off at a quarter inch , then it goes to 3/8 then it goes half , then it goes five eights and that's gonna be on your side .

And you also have those on the top for your reference .

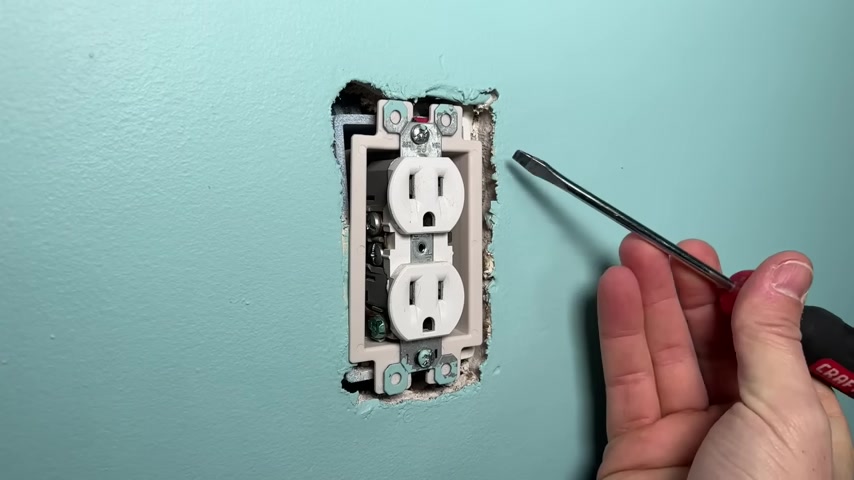

So the additional issue is even with the sunken in box , these tabs on your outlets or light switches will catch the outside surface .

But if you have an over cut situation like this where it's just really sloppy how the drywall was cut around the box .

Now , the tabs have nothing to hold onto .

So thus your outlet is sunken in .

So I'm gonna show you how to install those spacers to get this where we want it .

But also touch on code compliance and safety where you might need that insert .

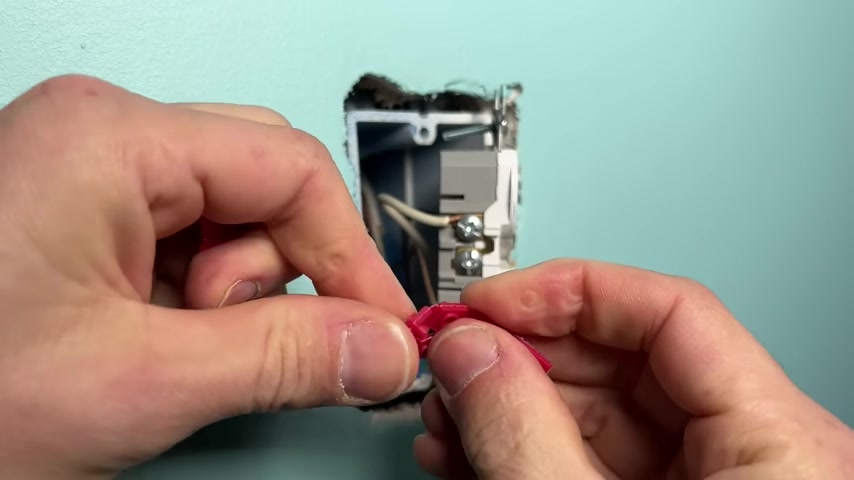

You can get these strips of spacers at pretty much any home improvement store or you'll see a link in the description where you can pick them up off of Amazon .

Each spacer that'd be considered one spacer is 1/8 of an inch thick and then they're stackable .

So that would be a quarter of an inch , 3/8 of an inch and so on .

And then that puts the opening on the same side so you can go ahead and insert that right around the top and bottom mounting screws .

Now , I wouldn't go crazy with these .

I would not go half inch .

I would not go 5/8 of an inch .

Uh You really want to cap out at about a quarter of an inch , maybe 3/8 of an inch depending on what you're working with .

If you had to offset with spacers more than that .

And you had a large opening like this , I would consider with a metal blade on zar , cutting the top and bottom mounting screw on that box and then putting a old work box in and I forgot the brand name , but there's old work boxes with two mounting screws from the inside .

So you could remove this rerun your Rox through the back of the , the old work box position that correctly and then screw your two mounting screws to your stud .

And then that's gonna get your box in the correct positioning .

So you're not spacing that out and having all this exposed material , which can be against code depending on your area , right .

So let me back these two mounting screws out so we can put our spacers on the top and bottom .

Now , one of those additional tips is these mounting screws are just standard number 6 32 .

So if you ever needed longer or just new mounting screws because they're stripped out or you lost some , I recommend grabbing a bag such as this , I get two inches .

Why I get two inches because I really don't want to carry one and a quarter , 1.5 , 2 inches .

I just want to carry two inches with me .

So I always have one that can work and then I just use my wire strippers and if you ever noticed you'd see 8-32 6-33 pretty much on any wire stripper out there .

Now , with this one , all you would have to do is insert that in , put it to your correct depth that you would like to shorten that bowl with a little pressure .

You'll go ahead and just snip that off .

And then you have your newly sized bowl and clean threads .

These wire strippers actually cut really clean and you do not have to thread the bold in and out which I know is a feature on some others .

If you want to see what other products that I'm using , what other products I recommend over time , which is always expanding and changing .

You can look down the description and we actually have an Amazon store where we always keep that updated and you'll see our electrical or plumbing or general tools just for your reference as you build out the tool set for your diy projects .

But back to getting this space .

So all I do is fold over .

I want a quarter inch spacer .

So I'd rip that off and then I do another one and rip that off .

Then I like to keep the opening facing the bottom .

So both on top and bottom , I'm gonna insert that spacer .

So the opening is facing down and that just helps hold that on there .

So hopefully it doesn't fall off or get misaligned as I tighten up the screws , then I just line things up and tighten it back down .

So now we have a secure outlet and I also do a dry fit on this wall plate and overall , it's looking much better .

Once we tighten that down , it's pretty much gonna be perfectly flush and it's gonna give us our finished product that we're looking for one other note before we jump into the insert and why you might need that for code compliance and safety is you can start to see this over cut , peeking out past the wall plate .

Now a lot of us would like to avoid the dry wall repair that might need to be done .

So just remember they do make larger wall plates .

This one is 3/8 of an inch longer and wider .

Just that additional width and length is going to give you the coverage you need for a nice fit and finish work .

Even when something is as grossly over cut as this was now , I don't necessarily recommend it , but they even have monster Jumbo plates which are three quarters of an inch longer and wider and that starts to get a little excessive .

But if you need it in a pinch without doing drywall , you don't have the paint match .

I get it .

This might also help you out .

Now , I'm gonna back these screws back out and show you how to use that insert and why to use that insert .

So in most areas code would limit the amount of non combustible like drywall material that's exposed to one quarter of an inch .

So even on this instance , I'm really right at that maximum .

If it goes past that , that is where you need a wall insert , right ?

And what that wall insert is gonna do , it's gonna encapsulate the outlet especially the hot side , so that additional material that would be exposed to those screw terminals is limited .

Now , it's encapsulated and you don't have in this case , noncoms or in another case , if you have , let's say wall paneling , wood wall paneling , well , you cannot have any wood wall paneling exposed .

How I know that is because I've done videos in the past where I had wall paneling exposed and many of the commenters called me out on it .

Uh and they were correct that should not be exposed and I should have used a insert like this to make sure it's code compliant and that it's safe .

So in this case , there's nothing too fancy with installing those inserts and often depending on how much length you have of your wire , you can just install those without undoing any of your screw terminals .

And then you're going to put your mounting screws through the two slots .

And as I said before , this really isn't gonna give me too much more material to catch on my drywall .

And since I have such a large over cut , I will use the combination of spacers and this insert to get everything lined up .

So now you can see the safety value where our terminals are encapsulated in this insert and no longer are they exposed to any material on the side .

Now , to finish this off , I am gonna use that larger wall plate just to make sure I don't have any openings peeking out .

Now , if you guys could do me a favor , I really appreciate jump down the comments and let me know what was new information for you .

What did you learn in this video ?

This is gonna help me understand you more as I try to continue to increase the value of these videos for you long term .

And speaking of information , check out this video right here .

It's gonna be a rapid fire of 10 things you might not know about a common outlet .

So thanks for joining me on this video and we'll catch you on the next one .

Take care .

Are you looking for a way to reach a wider audience and get more views on your videos?

Our innovative video to text transcribing service can help you do just that.

We provide accurate transcriptions of your videos along with visual content that will help you attract new viewers and keep them engaged. Plus, our data analytics and ad campaign tools can help you monetize your content and maximize your revenue.

Let's partner up and take your video content to the next level!

Contact us today to learn more.