https://www.youtube.com/watch?v=wJk8EEyNfvU

Rebuilding A Tesla With A Camaro Engine

Uh my name is Rich and I run a youtube channel called Rich Rebuilds .

And uh on that youtube channel , we just make a lot of really weird fun stuff .

So we start out with mostly doing E V s .

We switch to gas and now we do both gas and E V s and just have a really funny time .

It's funny because once you build a repair a Tesla , you kind of fix it and you go from there , there's no real upgrades for it .

Uh So many things are electronically controlled .

It doesn't make it as fun for the hot rodders out there .

So I said to myself , you know , what , how do we mix the two things ?

How do we have , you know , a , a really good looking car and combining it with the tune of a , of , of a classic V eight engine .

So we decided just to combine the two , a lot of people think that , oh , you took a brand new Tesla and toured a park .

It's like , no , no , it wasn't a flood and Tesla won't sell you batteries and motors to repair it .

So I said , you know what if Tesla won't then uh Jennifer Motors will .

So it was a Camaro S s that was completely destroyed and the engine was available and uh decided to put it in the Tesla .

For me , it's one of those things where it has to do with recycling .

So they were both just like rat cars sitting in a field and I said , why have them both just sitting there , why not combine the two and make something that actually runs and functions ?

So I spent the first few months actually stripping it down , taking out all the interior components , pressure , washing everything and just getting all of like the stench and like the sewage out of the car .

So I took both motors out .

Both motors were toast .

You ready ?

Water , man .

There's tons of water in there .

Uh The battery pack was pretty much toast because under water for so long , you know , um , anything short of aluminum was shipped out of the car .

So I think a lot of measuring and prep was the hardest part , making sure the engine sits straight and true in the car because don't forget , not only do you have to have , make sure the engine sits well in the car , but there's also a transmission that adds another few feet and there's also a really long drive shaft that spins thousands upon thousands of R PM that are literally sitting right between your legs that has to be straight as well .

Like a lot of different angles and things had to be straight in order for the car to even roll down the road , believe it or not , it almost makes sense that the V eight fits so well .

Once you take out the front motor , there's so much room in there and the L S3 is actually so narrow , it actually fit in there pretty well .

So what we noticed was that when we brought the car to Sima , if we had the hood open , everyone would just walk by it because the install was so clean .

It was only until they saw the Tesla logo that everyone just kind of a rubberneck stopped and went towards the car .

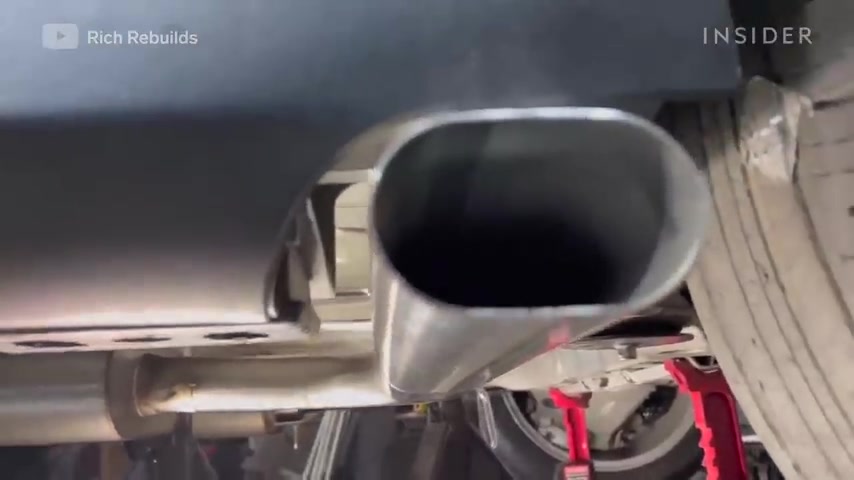

The exhaust fabrication process was interesting .

Um because battery pack for a Tesla model last weighs about , I would say between 11 and £1200 .

So because the old battery was , you know , about four inches thick and so heavy and it tucked in .

So underneath the car once he removed did .

And we made the exhaust system , we decided to go with oval tubing because when you go with oval tubing , kind of like NAS cars use , you actually save a lot of space going oval versus completely circular .

So if you notice we have a side exit exhaust system , most cars have a rear exit exhaust where it actually comes right under the rear bumper .

We couldn't do that because the independent rear suspension was so large , the exhaust actually couldn't go past it .

So we just terminated the exhaust system right to the sides right before the , the rear wheels .

Yeah , one of the biggest challenges was uh the fabrication of the transmission tunnel , you know , in a Tesla , it's one of the few cars that are made , it has a completely flat floor .

You know , most cars nowadays that are rear wheel drive , there's a tunnel going from the front all the way to the back .

This one didn't have that .

So we had to make our own and it was , it was definitely challenging .

Uh So we have , we have a great fabricator , Joshua that actually was able to cut the car in half down the middle and actually build a transmission tunnel .

One of the other difficult issues we went through with this car was the wiring so we can completely stripped the car down to the bare frame .

It was just literally just a shell and we had to rewire the entire car all over again .

And we actually removed about 50 to 60% of the car's entire wiring on its like the battery pack is not there .

That's one set of wiring , high voltage cables .

Uh There was uh wiring to the rear motors , the front motors , those are both gone .

You know , we save some a significant amount of weight going from the older lithium powered battery pack to the uh to the internal combustion engine .

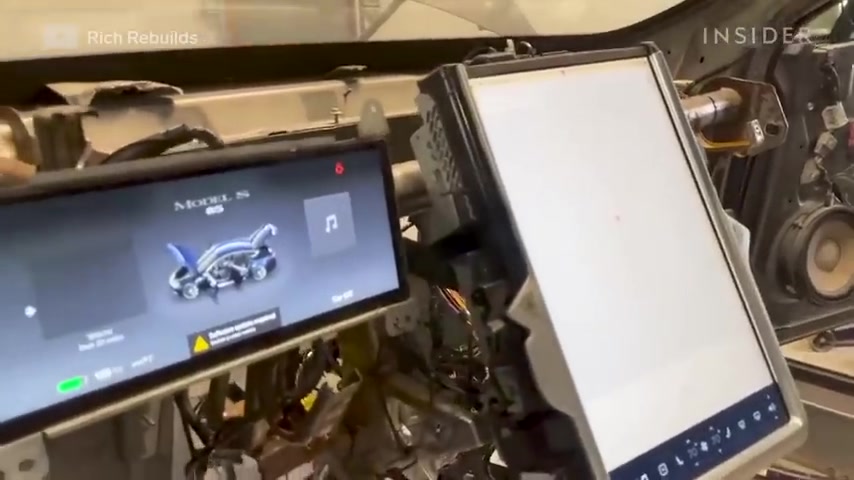

The , the car still has the touch screen .

Uh uh it still has the instrument cluster and all the functions work , the navigation works .

The Bluetooth works .

So when you stood in the car , you could , you know , push buttons and play with different functions of the vehicle and it , it does work .

I am very satisfied with how it runs .

Yeah , we still need to do some fine tuning to it .

But at the end of the day when you sit in it and you drive it , you , I , you almost forget that it's a Tesla .

Like , you're just thinking that you're driving like a regular , you know , powerful V eight engine car and it's , it's , it's really weird because if you don't think about it , you're like , ok , this is pretty cool as a manual I'm doing my thing .

But you really have to take a step back and say to yourself , this car never had any of this .

Are you looking for a way to reach a wider audience and get more views on your videos?

Our innovative video to text transcribing service can help you do just that.

We provide accurate transcriptions of your videos along with visual content that will help you attract new viewers and keep them engaged. Plus, our data analytics and ad campaign tools can help you monetize your content and maximize your revenue.

Let's partner up and take your video content to the next level!

Contact us today to learn more.