https://www.youtube.com/watch?v=d13yFxRIcX4

Strangest Automotive Engines - The 1961-63 Pontiac Tempest & Its 'Trophy 4' _ 'Half 389 V8' Engine

In 1961 Pontiac introduced a revolutionary new small car that contained within it numerous innovations and oddities .

The 1961 Tempest , the Tempest was designed to provide broad appeal to numerous potential buyers , including individuals who would purchase it as a second car , as well as those who needed it as a family sedan with full size six passenger comfort .

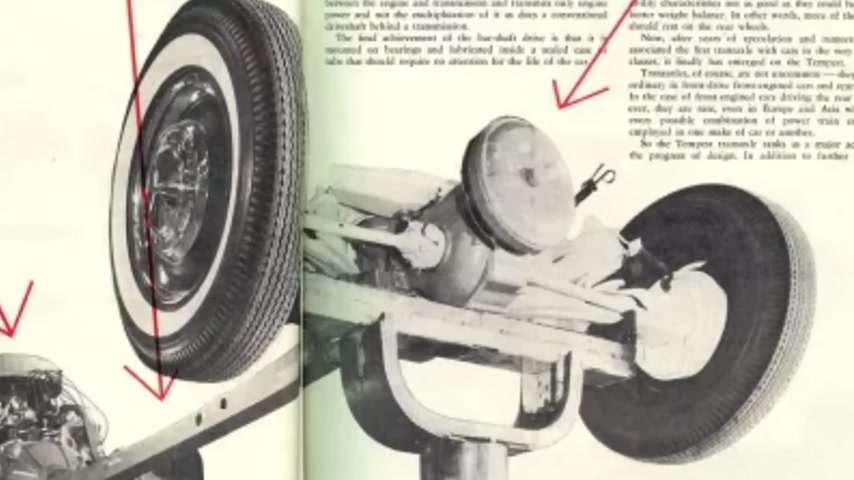

Earlier Pontiac division research had shown that elimination of the typical rear wheel drive transmission tunnel enabled front seat foot room to increase by about 50% providing such so called fidget room in a small car was deemed to be highly desirable .

Hence , the Tempest went to market with a novel rear mounted transmission that was neatly packaged between the rear seat and the rear axle .

The unique engineering solution was coupled with numerous other novelties to make the Tempus work .

However , the subject of today's video is the engine that was mounted to the opposing end of the Tempest from the rear transmission .

Pontiac's new for 1961 trophy four cylinder engine , a four cylinder engine .

What on earth is so special about a four cylinder engine ?

I can hear some of the viewers say , well , stay tuned and find out what made the tempest with its 194.5 cubic inch trophy four cylinder under hood such a unique marketplace offering in the depths of the late 1950 S Eisenhower recession .

Pontiac planners determined there was a greater need for an economy focused car that was smaller in size , more fuel efficient , but also one that offered enough interior space to seat six adults .

Given the division was concentrating on relatively large V eight engines .

A different power plant was needed to ensure that the upcoming Tempest would be able to achieve the right balance of power and fuel economy .

Thus , Pontiac engineers set to work on evaluating numerous in line and V configuration engines made of both aluminum and cast iron .

Key objectives for the engine program included performance on par with competitive six cylinder powered vehicles , high level of parts and tooling sharing with Pontiac's existing V eight engines and simplicity of design and operation .

After some deliberation , Pontiac engineers decided they wanted to try a four cylinder engine based off of their popular 389 cubic inch V eight .

In order to fabricate a quick prototype , the team disconnected the valve gear from one bank of cylinders in a standard 3 89 V eight and drilled large holes in four of the V eight pistons .

They then ran the engine in a standard sized Pontiac to see what happened after it was able to achieve over 90 miles an hour with seemingly respectable performance .

They fabricated numerous engines by cutting one bank of cylinders off of the 3 89 V eight and outfitting the engine with the required internals like an appropriate crank shaft and camshaft to further refine their testing .

It may sound crazy but this initial development idea largely made it through to production though , with numerous engineering modifications to make it work satisfactorily .

the end result of all this engineering effort was a literal half 3 89 cubic inch V eight .

The right bank of the 389 that is with the cylinders canted 45 degrees similar to their arrangement on the larger V eight , the vacant space where the other half of the V eight would be able to house various accessories and even the engine starter .

Moreover , many engine parts including cylinder heads , pistons , connecting rods , main bearings and valve train components .

Among other things were fully interchangeable with the Pontiac 3 89 only elements of the cylinder block , crankshaft intake manifold , carburetor , air cleaner and a few other minor accessory drive components were completely different from the 389 .

Thus in total , out of 44 major engine parts or assemblies , 28 were identical to the 3 89 5 had a slight variation and 11 were completely different .

So much was interchangeable between the trophy four and the larger 3 89 V eight that cylinder blocks were able to be machined on the same machining line with the trophy four rotating which machining line it would follow depending upon the day of the week .

In order to minimize tooling wear .

As the engine progressed in its testing , it was put through the usual paces including grueling wear tests .

One of which required the engine to withstand 100 hours without failure at 4500 R PM .

Essentially the equivalent of 11,200 miles at 112 MPH on the test track at Gm's Milford Michigan proving ground .

Engineers were able to drive a Tempus 20,000 miles at maximum speed before burning out a connecting rod bearing when it came to refinement as well as durability .

Engineers not surprisingly found that the trophy four V eight was not inherently smooth .

A number of steps were taken to ensure that the engine and mounted accessories would provide years of trouble free service .

Some under hood items like the air cleaner required a side brace .

In addition to the standard mounting due to the trophy four's inherent vibrations , the generator also required extra rigid cast iron supports to deal with this vibration .

The exhaust crossover pipe required bracketing to help prevent fatigue and the timing chain had to be modified also because of the four cylinders inherent forces similar to the 3d nine V eight rotating parts were balanced after the assembly of engine crankshaft pistons and connecting rods into the block .

And Pontiac engineers believe that this was the first application of engine balancing to the crankshaft , in particular of a four cylinder engine .

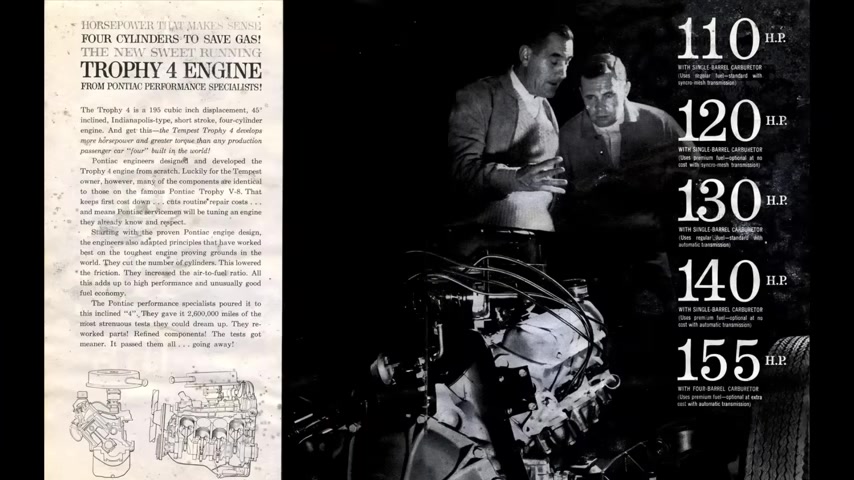

Once drive and durability testing was finalized , engineers began to tune the four cylinder to enable it to have a number of potential configurations for the buying public .

When all was settled and done there ended up being five horsepower configurations of the trophy four in 1961 ranging from a lower compression one barrel carburetor , 110 horsepower variant , which was standard with the manual transmissions all the way up to 155 horsepower variant , topped with a four barrel carburetor and high compression trophy four s were also mounted 1.4 inches to the left of center in order to better enhance the weight distribution in the cars .

And for the buyer who wanted even more power , a power pack option for 1962 arrived with a four barrel carburetor and a bit more increased power with 166 horsepower .

Now becoming the most powerful trophy four engine overall .

The trophy four engine was a relative success but didn't last very long as it was only produced for the 1961 to 63 model years before the Tempus was redesigned and the trophy four was sunset .

It did have some inherent issues .

As previously mentioned , vibration was not its strong suit but it was cushioned by super flexible engine mounts .

Designed to isolate the trophy four from the car's body itself and the forces were further dampened by the tempest unusual drive train that helped distribute some of the forces through the torque two back to the rear mounted transmission .

Overall , the trophy four and the 1961 to 63 tempest that it was contained in were certainly unique engineering solutions to the previously stated problem of trying to produce a relatively small car with large amounts of interior space for the American public .

And overall , the Tempest sold quite well during the 1961 to 63 model years selling about 100,000 units in 1961 and about 100 and 50,000 units in 1962 .

Before sales settled down a bit in 1963 at about 75,000 units , there was an optional engine for the Tempest that was not a four cylinder during these years and it was G MS aluminum small block V eight .

We can talk more about that particular engine at another time .

I hope you enjoyed this special on the 1961 to 3 Tempus trophy four .

Let's close out now with an ad from 1963 for the Tempus that talks a bit about the trophy four and is the last year before the Tempus would be redesigned for 1964 and become a larger car that would also help spring another Pontiac legend , the G T O contact new temper series .

Fight with high wing bucket seats , full carpeting and four Pontiac punch and bus at a punches .

Hold to the idea that gas economy means you can get up to an honest 166 horsepower from the gas saving four in a campus is balanced like none of the others with engine in front transmission in the rear there for fighting traction and getaway bricks independent with swing axles help Tampas take ruts , grilled and hills in flat level dry if you want custom trim , full carpeting posh punch and low price sample .

Pontiacs , Tempus Leon at your Pontiac dealer .

Now .

Are you looking for a way to reach a wider audience and get more views on your videos?

Our innovative video to text transcribing service can help you do just that.

We provide accurate transcriptions of your videos along with visual content that will help you attract new viewers and keep them engaged. Plus, our data analytics and ad campaign tools can help you monetize your content and maximize your revenue.

Let's partner up and take your video content to the next level!

Contact us today to learn more.