https://youtu.be/kOhlxeHXfBA?si=L-wkqcD2Q9vH4BOW

Heidolph DAA Video

Come to the first video of our new series about excellence in evaporation .

Today , we want to introduce a smart feature to automate some of the most relevant process steps of rotor evaporation processes .

The dynamic autoaccurate or short DAA mode , it's a smart program to detect and to address a single or even a multiple boiling point automatically .

In this video , we will show you how this feature can boost the efficiency in your lap , can avoid undesirable side effects like foaming or bumping , and how it can ensure a stable , constant evaporation without readjustments or monitoring .

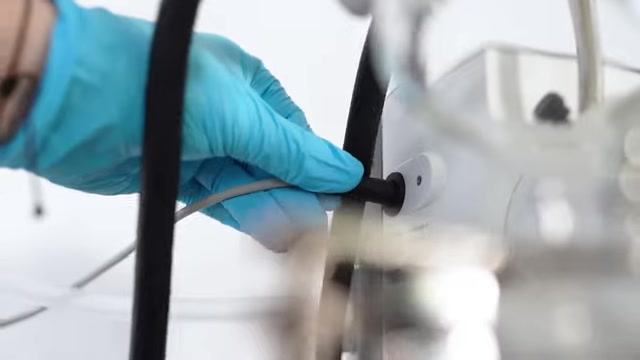

You can connect the outer accurate sensor , which is an optional accessory , to your High Vap Expert or Ultimate control unit .

The system will recognize the sensor automatically and will allow to start the so called dynamic outer accurate evaporation .

The first and most important change on the display is that you won't see the set vacuum anymore as the program automatically search for the right vacuum level , so you do not need to know the right parameter .

The system will do the job for you .

The process starts with an automatic self check to ensure that the temperature at the most relevant position , which is the lowest point of our condensation zone , is stable .

If this is the case , the program starts now to surge carefully and slow enough to the right vacuum level in order to trigger the initial boiling .

This is very important to avoid a too fast evacuation , which could lead to the occurrence of foam or splashes .

As soon as the first rising wafer increase the temperature at our point of measurement , the system reacts , and we keep the vacuum level and visit the wafer load on our condenser constant .

After a while of constant evaporation , the residue level of our focus solvent decreased and with it , the created and rising amount of wafer .

In a manual process , you would have to readjust the vacuum now manually or you accept a slow and not fully completed separation .

The DAA program will adjust the vacuum automatically several times to maintain an efficient and fast evaporation and a good separation from solvent to solvent or solvent from a solid or powder .

At the end , the system detect no vapor load anymore via a recovering temperature level on the sensor and will finish the process automatically .

But the DAA mode offers even more function .

For example , you can evaporate even multiple solvents 1 by 1 out of a complex mixture .

This helps to avoid the chaos of foaming and pumping inside of the glassware system , which could occur if you address different boiling points at the same time .

Also noteworthy , you can fine tune the efficiency of your automatic evaporation with an allowed delta t value .

For example , if you work with a strong cooling source , you can adjust the tolerance of the sensor to keep the automatic evaporation always on the most efficient level according to your physical system limits .

So summarizing , you saw that the dynamic auto accurate function allows you to run an evaporation process on a perfectly balanced and most efficient level without the need of monitoring .

You can invest this time into other research tasks .

Moreover , due to the very sensitive step by step evacuation process , it can avoid foaming and bumping , and it addresses and finds the boiling point automatically .

If you are interested , our application specialists are happy to assist you and to check which improvement potential the DAA mode offers for your specific application .

Well , I hope you enjoyed that information .

We We're always passionate to support you in your way to excellence in research , to your way to excellence in evaporation .

Thanks for watching .

Are you looking for a way to reach a wider audience and get more views on your videos?

Our innovative video to text transcribing service can help you do just that.

We provide accurate transcriptions of your videos along with visual content that will help you attract new viewers and keep them engaged. Plus, our data analytics and ad campaign tools can help you monetize your content and maximize your revenue.

Let's partner up and take your video content to the next level!

Contact us today to learn more.